Low-dielectric high-Q lithium magnesium phosphate dielectric material and preparation method thereof

A lithium-magnesium-phosphorus-based, dielectric material technology, applied in the field of ceramic materials, can solve the problem of low Q×f value of dielectric materials, and achieve the effects of simple preparation process, excellent microwave dielectric properties, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

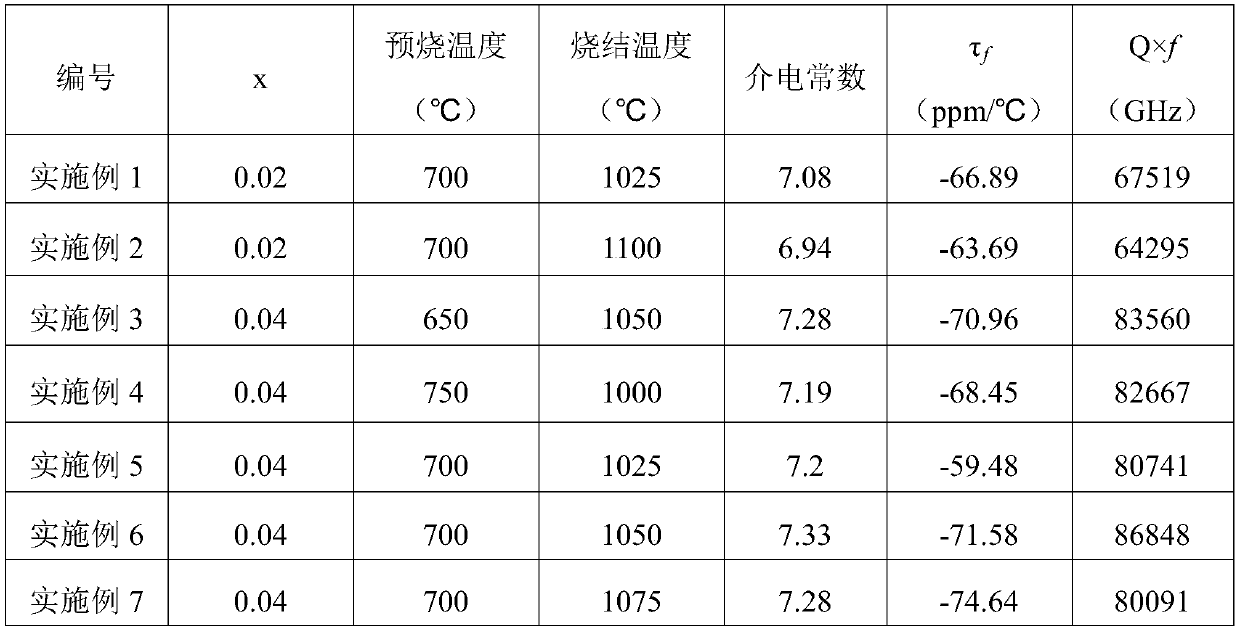

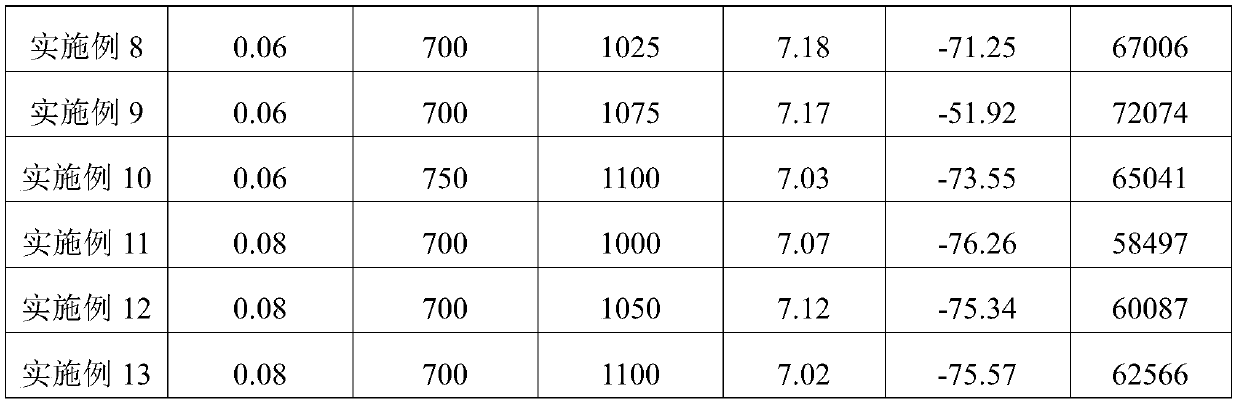

Examples

Embodiment 1

[0028] 1. According to LiMg(P 0.98 Nb 0.02 )O 4 , called Li 2 CO 3 -5.7538g, MgO-6.2769g, NH 4 h 2 PO 4 -17.5554g, Nb 2 o 5 -0.4140g of ingredients, 30g in total; the mixed powder is added to a polyester tank, after adding 180ml of deionized water and 160g of zirconium balls, ball milled on a planetary ball mill for 3 hours, and the speed of the ball mill is 250 rpm;

[0029] 2. Place the ball-milled raw materials in a drying oven to dry and pass through a 40-mesh sieve to obtain a powder with uniform particles;

[0030] 3. First heat the powder to 550°C for 1 hour, and then continue to heat up to 700°C for 4 hours;

[0031] 4. Put the calcined powder into a polyester tank, ball mill it for 6 hours for the second time, dry it after discharge, and pass through a 40-mesh sieve; then add 7% paraffin wax as a binder for granulation, and Pass through an 80-mesh sieve; then press a powder tablet press with a pressure of 4MPa to form a green body with a diameter of 10mm and...

Embodiment 2

[0035] 1. According to LiMg(P 0.98 Nb 0.02 )O 4 , called Li 2 CO 3 -5.7538g, MgO-6.2769g, NH 4 h 2 PO 4 -17.5554g, Nb 2 o 5 -0.4140g of ingredients, 30g in total; the mixed powder is added to the polyester tank, after adding 180ml of deionized water and 160g of zirconium balls, ball mill on a planetary ball mill for 1 hour, and the speed of the ball mill is 250 rpm;

[0036]2. Place the ball-milled raw materials in a drying oven to dry and pass through a 40-mesh sieve to obtain a powder with uniform particles;

[0037] 3. First heat the powder to 500°C for 2 hours, and then continue to heat up to 700°C for 5 hours;

[0038] 4. Put the calcined powder into a polyester tank, ball mill it for the second time for 7 hours, dry it after discharge, and pass through a 40-mesh sieve; then add 8% paraffin wax as a binder for granulation, and Pass through an 80-mesh sieve; then press a powder tablet press with a pressure of 4MPa to form a green body with a diameter of 10mm and ...

Embodiment 3

[0042] 1. According to LiMg(P 0.96 Nb 0.04 )O 4 , called Li 2 CO 3 -5.7431g, MgO-6.2652g, NH 4 h 2 PO 4 -17.1653g, Nb 2 o 5 -0.8264g of ingredients, 30g in total; the mixed powder was added to a polyester tank, after adding 180ml of deionized water and 160g of zirconium balls, ball milled on a planetary ball mill for 2 hours, and the speed of the ball mill was 250 rpm;

[0043] 2. Place the ball-milled raw materials in a drying oven to dry and pass through a 40-mesh sieve to obtain a powder with uniform particles;

[0044] 3. First heat the powder to 550°C for 3 hours, and then continue to heat up to 650°C for 6 hours;

[0045] 4. Put the calcined powder into a polyester tank, ball mill it twice for 8 hours, dry it after discharge, and pass through a 40-mesh sieve; then add 8% paraffin wax as a binder for granulation, and Pass through an 80-mesh sieve; then press a powder tablet press with a pressure of 4MPa to form a green body with a diameter of 10mm and a thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com