Brass alloy smelting device and brass alloy smelting method

A brass alloy and alloy technology, applied in the field of brass alloy smelting equipment, can solve problems such as uneven distribution, uneven flame phenomenon, and uneven temperature of alloy melt, so as to reduce the degree of macro segregation and the degree of macro segregation The effect of reducing and precisely controlling the pouring temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

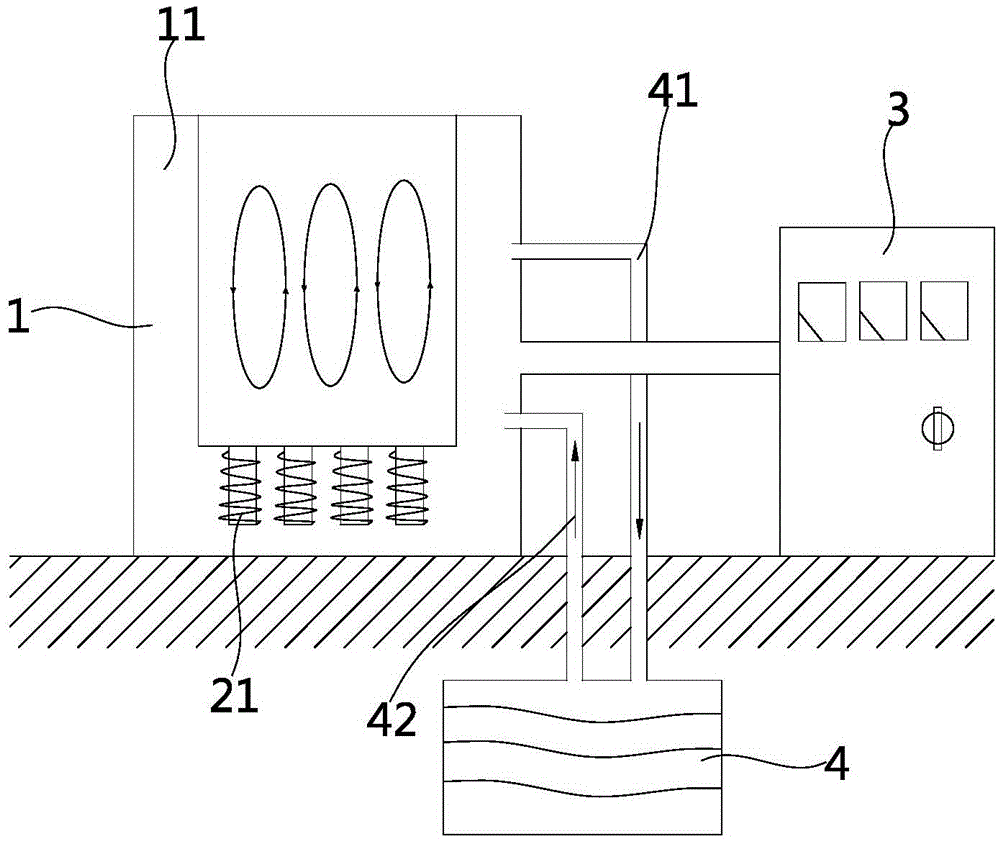

[0030] Such as figure 1As shown, the electromagnetic generator includes a first electromagnetic generator 21, the first electromagnetic generator 21 is installed at the bottom of the smelting furnace 1, the first electromagnetic generator 21 will generate an alternating magnetic field when energized, because the alloy melt has a conductive Therefore, the alloy melt will be subjected to the Lorentz force F, and the expression of the Lorentz force F is:

[0031] F = ( 1 / μ m ) ( ▿ × B ) × B Formula 1)

[0032] In the formula: is the Hamiltonian, B is the magnetic induction, μ m is the magnetic permeability.

[0033] Since the alternating magnetic field will produce different magnetic induction intensities, the Lorentz force F generated in the alloy me...

Embodiment 2

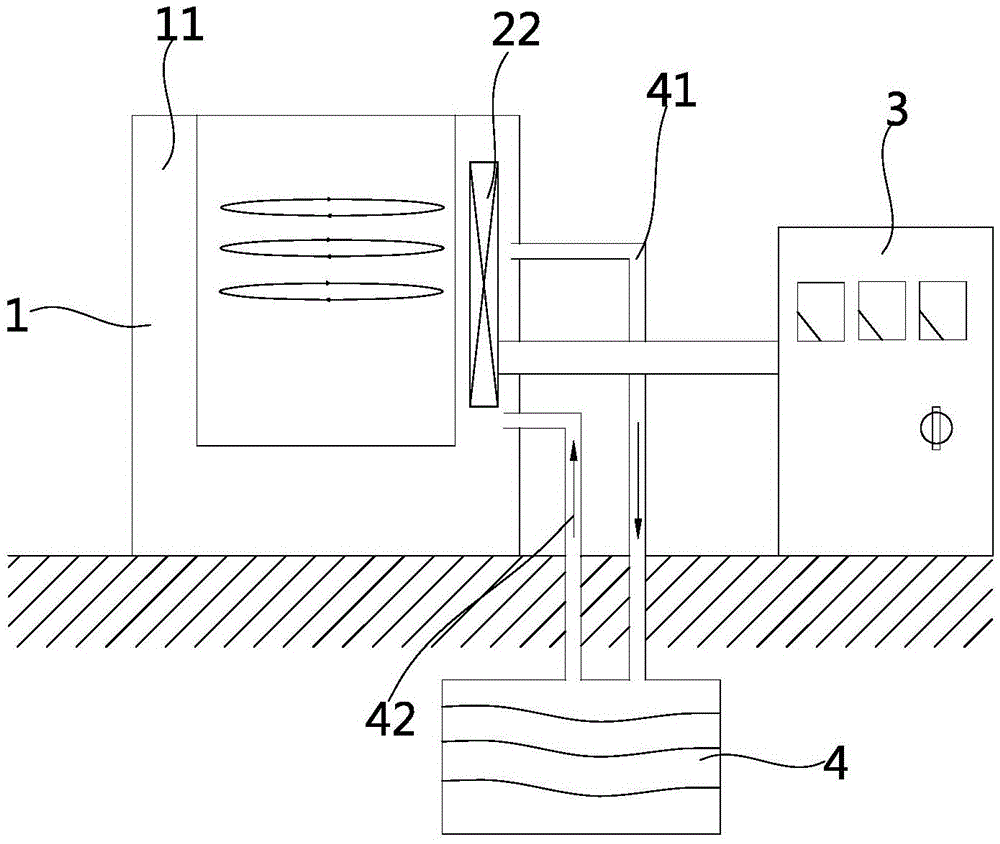

[0040] Such as figure 2 As shown, the electromagnetic generator includes a second electromagnetic generator 22, and the second electromagnetic generator 22 is installed on the side of the melting furnace 1. When the second electromagnetic generator 22 is energized, according to the formula (1) to the formula ( 3) It can be seen that the second electromagnetic generator 22 will cause the alloy melt to generate horizontal convection, and the horizontal convection of the alloy melt has the following benefits: 1. The alloy melt with a low temperature in the center of the melting furnace 1 and the two Heat transfer occurs between the alloy melts with high side temperature, thereby reducing the temperature gradient of the alloy melt, and promoting the uniform fire phenomenon; 2. The zinc element can be evenly distributed in the alloy melt, reducing the macro segregation of the ingot degree.

Embodiment 3

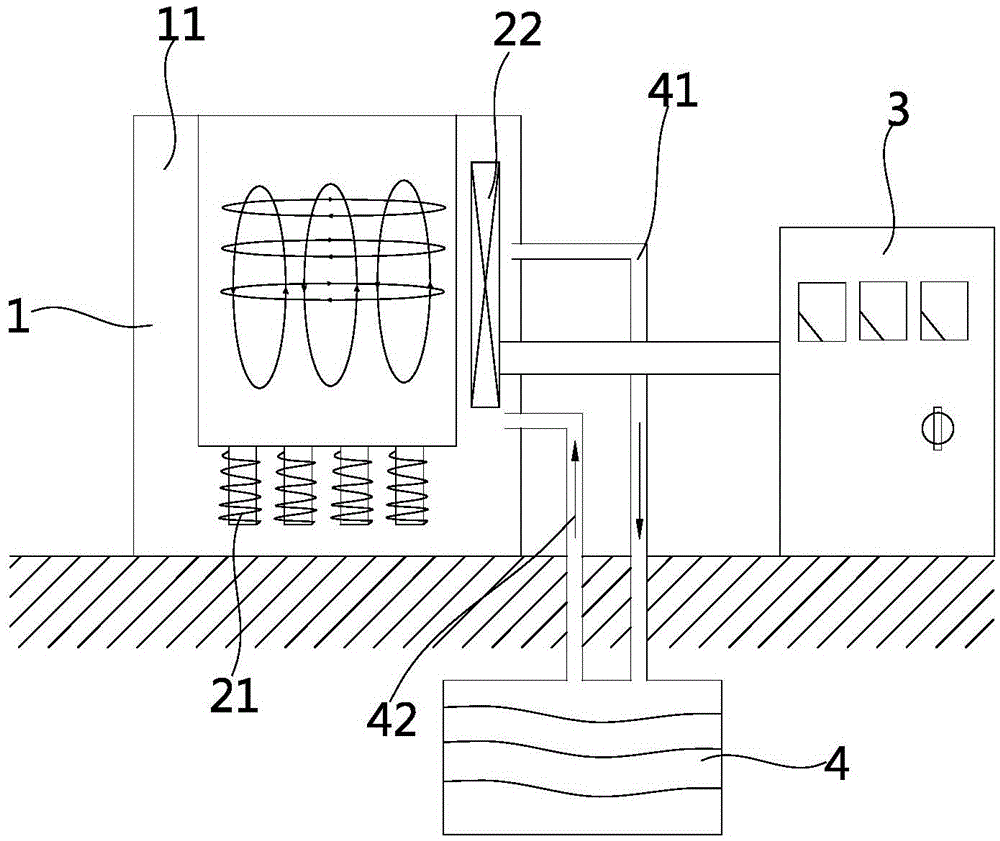

[0042] Such as image 3 As shown, the electromagnetic generator includes a first electromagnetic generator 21 and a second electromagnetic generator 22. The first electromagnetic generator 21 is installed at the bottom of the melting furnace 1, and the second electromagnetic generator 22 is installed at the side of the melting furnace 1. The magnetic induction of the electromagnetic generator 21 and the second electromagnetic generator 22 is coupled to each other, so that the flow of the alloy melt can flow in the vertical direction and the horizontal direction. Compared with the first embodiment and the second embodiment, the alloy melt in this embodiment The flow in the vertical direction and the horizontal direction has the following benefits: 1, heat transfer can occur between the low temperature alloy melt and the high temperature alloy melt in the smelting furnace 1, and the low temperature of the central part in the smelting furnace 1 Heat transfer occurs between the al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com