Rapid-construction method used for overall installation of large-span steel truss

A technology of overall installation and construction method, applied in the processing of building materials, construction, building structure, etc., can solve the problems of short operation time, high safety risk, long construction period, etc., to achieve shortened construction period, simple construction technology, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0026] Take the overall installation and construction of a long-span steel truss as an example.

[0027] Specific steps:

[0028] 1), steel truss structure;

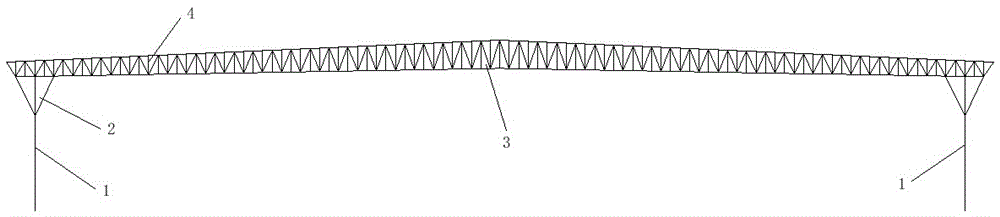

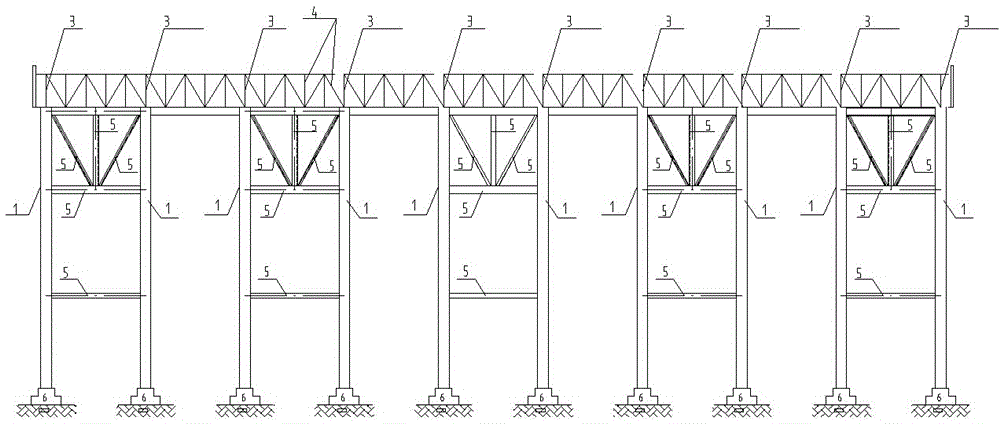

[0029] The steel truss structure can be a single-piece steel truss. The main truss 3 adopts a 58.8m single-span steel truss. The rod adopts ∠80×8 angle steel, the web rod adopts [6.3, [8; the steel column 1 adopts φ720×12 steel pipe, and the steel column diagonal brace 2 adopts [22a; the foundation 6 adopts column-type enlarged foundation.

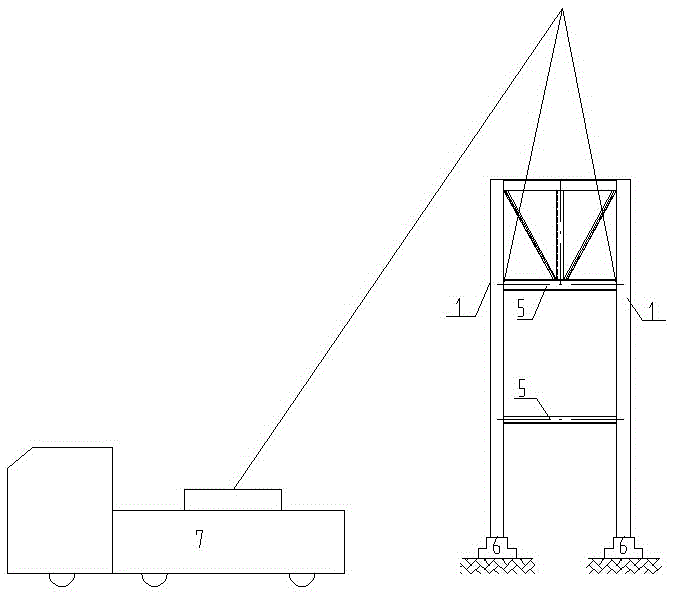

[0030] 2), steel column installation;

[0031] The hoisting of steel column 1 adopts the direct hoisting method. Two steel columns 1 are assembled into a unified whole by using inter-column supports 2, and placed on the ground lying flat; when lifting, the crane hook directly raises the column body so that the column body is in a vertical state, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com