Coal gas pressurizing machine

A pressurizer and gas technology, applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems affecting the safe operation of fans, gas leakage, etc., and achieve ingenious design and installation, high air tightness, and improved efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

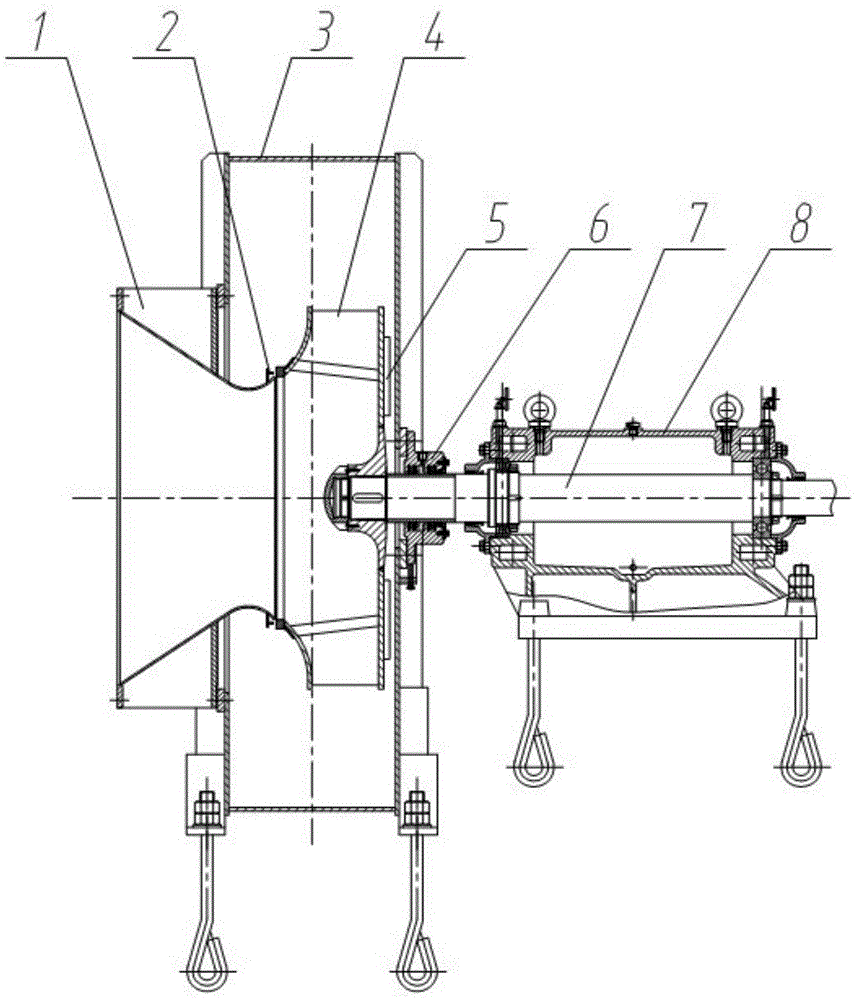

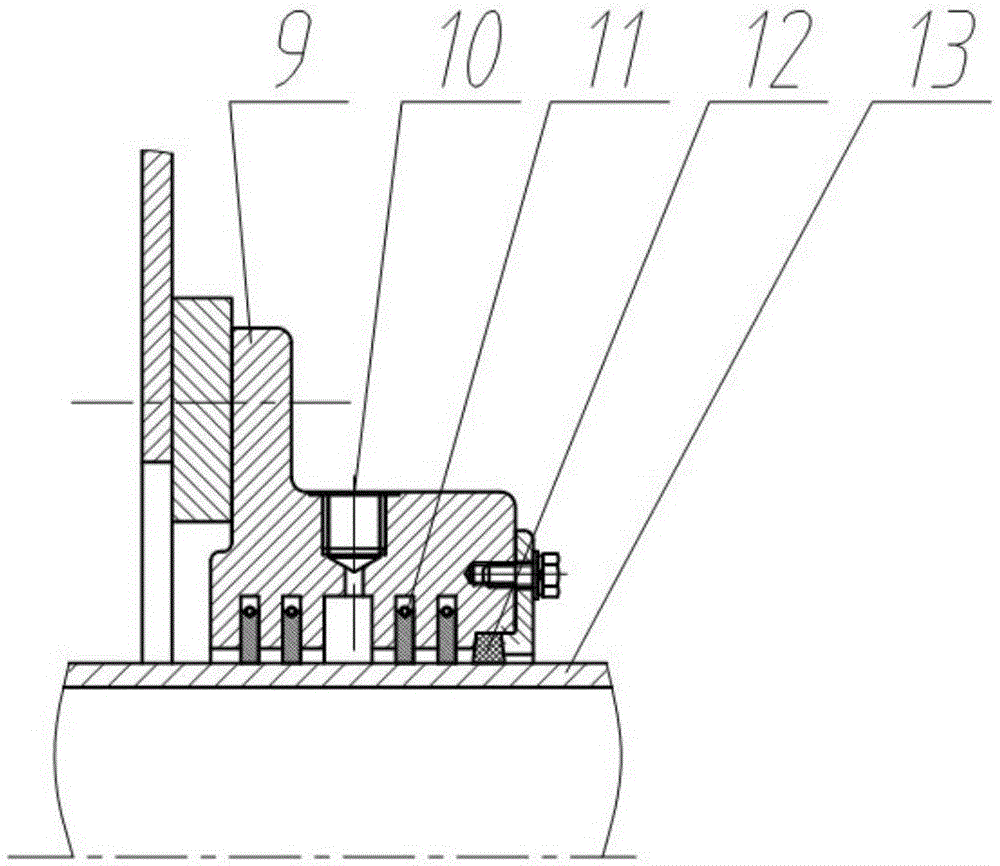

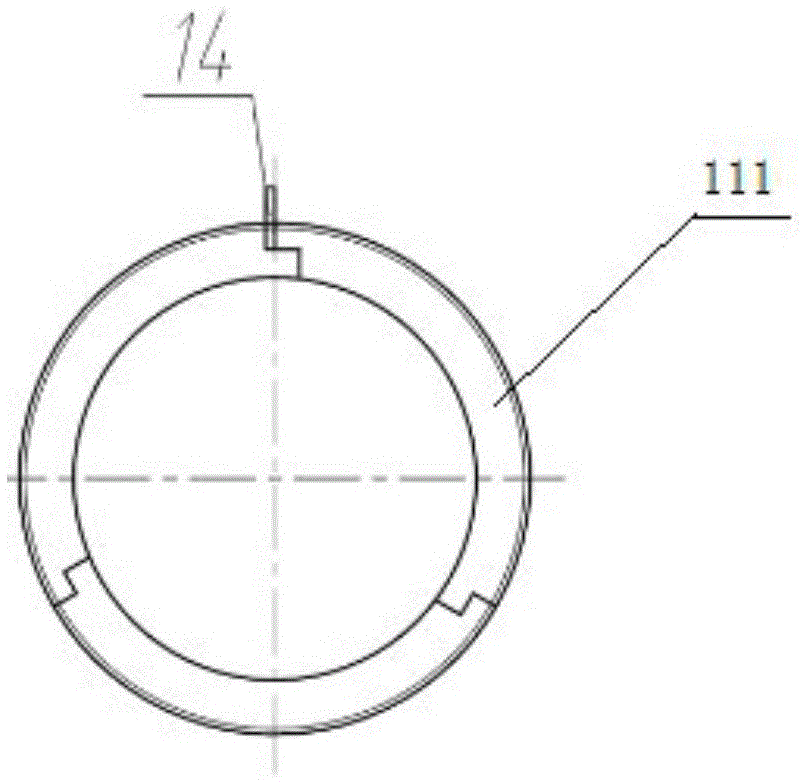

[0028] One embodiment of the present invention discloses a gas compressor, such as figure 1 Shown: including air inlet 1, casing 3, impeller 4, main shaft sealing device 6, main shaft 7 and bearing box 8; the front side of casing 3 is provided with a connecting flange surface, and air inlet 1 is fixed on the connecting flange by bolts On the surface, the impeller 4 is arranged in the casing 3, the main shaft 7 penetrates into the rear side of the impeller 4 in the casing 3, and the impeller 4 and the main shaft 7 can be connected by a flat key; the flat key connection can transmit torque and realize the radial direction of the impeller 4. At the same time, it is necessary to use the lock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com