Annular type combined password locking control valve

A combination of password and control valve technology, which is applied in the direction of valve details, valve devices, and devices to prevent accidental or unauthorized actions, can solve problems that plague enterprises such as energy-saving and efficient development, difficulty in adapting quickly and effectively, and increased production and operation costs. , to achieve the effect of solving economic losses and troubles, perfect functional design, and high security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

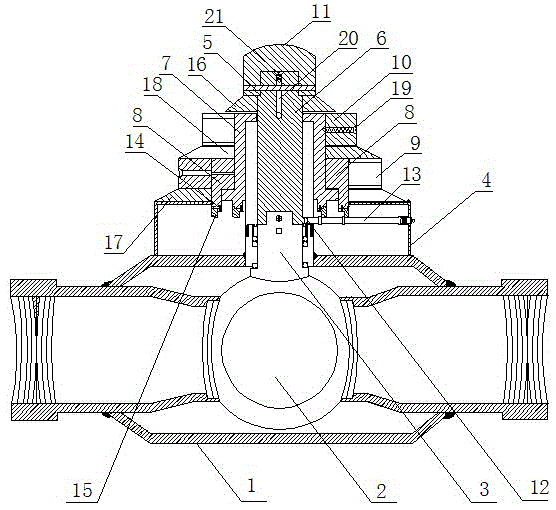

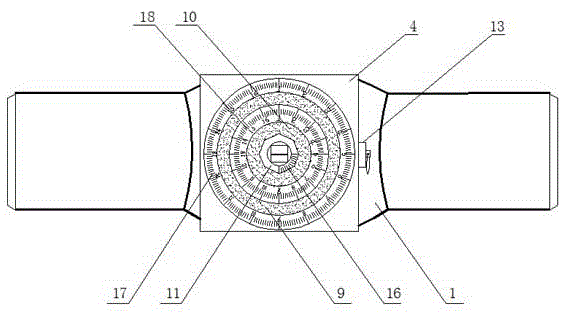

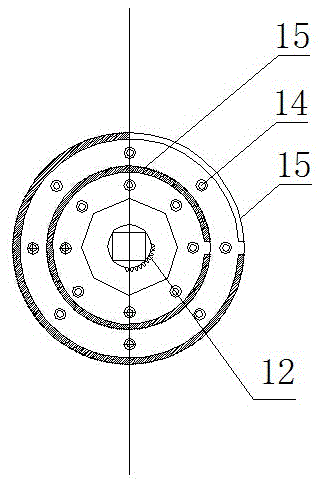

[0018] The ring-type combined password lock control valve of the present invention is composed of a valve housing 1, a valve core 2, a valve shaft 3 and a password lock mechanism, and a built-in lock fixing box 4 and a valve housing 1 are fixed directly above the valve housing 1. The valve shaft 3 connected to the top of the core 2 is placed in the built-in lock fixing box 4, and the bottom end of the diameter valve shaft 6 is placed in the built-in lock fixing box 4 and is fixedly connected with the top of the valve shaft 3 through a pin shaft. The middle and lower part of the diameter valve shaft 6 is sequentially set with the lock code ring I7 and the lock code ring II8 from the inside to the outside. The bottoms of the lock code ring I7 and the lock code ring II8 are placed in the built-in lock fixing box 4. Coded manual handle II9 is set on the code lock ring II8, coded manual handle I10 is set on the lock code ring I7 above the coded manual handle II9, and the valve sha...

Embodiment 2

[0020] The ring-type combined password lock control valve of the present invention is composed of a valve housing 1, a valve core 2, a valve shaft 3 and a password lock mechanism, and a built-in lock fixing box 4 and a valve housing 1 are fixed directly above the valve housing 1. The valve shaft 3 connected to the top of the core 2 is placed in the built-in lock fixing box 4, and the bottom end of the diameter valve shaft 6 is placed in the built-in lock fixing box 4 and is fixedly connected with the top of the valve shaft 3 through a pin shaft. The middle and lower part of the diameter valve shaft 6 is sequentially set with the lock code ring I7 and the lock code ring II8 from the inside to the outside. The bottoms of the lock code ring I7 and the lock code ring II8 are placed in the built-in lock fixing box 4. Coded manual handle II9 is set on the code lock ring II8, coded manual handle I10 is set on the lock code ring I7 above the coded manual handle II9, and the valve sha...

Embodiment 3

[0022] The ring-type combined password lock control valve of the present invention is composed of a valve housing 1, a valve core 2, a valve shaft 3 and a password lock mechanism, and a built-in lock fixing box 4 and a valve housing 1 are fixed directly above the valve housing 1. The valve shaft 3 connected to the top of the core 2 is placed in the built-in lock fixing box 4, and the bottom end of the diameter valve shaft 6 is placed in the built-in lock fixing box 4 and is fixedly connected with the top of the valve shaft 3 through a pin shaft. The middle and lower part of the diameter valve shaft 6 is sequentially set with the lock code ring I7 and the lock code ring II8 from the inside to the outside. The upper part of the code circle II8 is fixedly connected with the password manual handle II9, and the upper part of the code lock ring I7 above the password manual handle II9 is set with the password manual handle I10, and the top of the diameter valve shaft 6 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com