Novel optical lens acquiring long focal depth Bessel gauss light beams through focusing

A technology of optical lens and focusing spot, which is applied in the direction of optics, lens, optical components, etc., can solve the problem of extremely high precision of mechanical assembly, and achieve the effect of improving laser fine processing technology and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

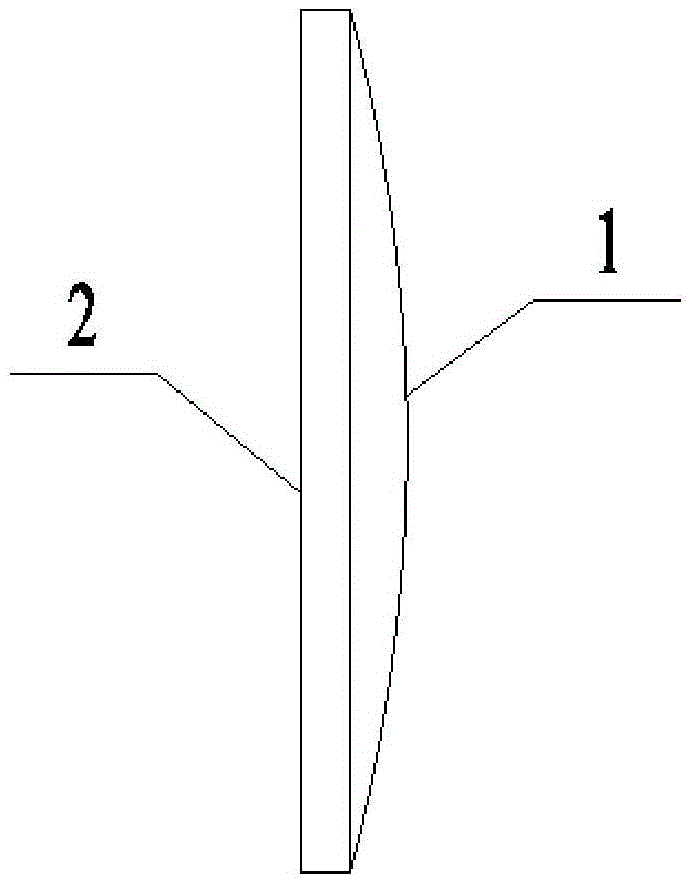

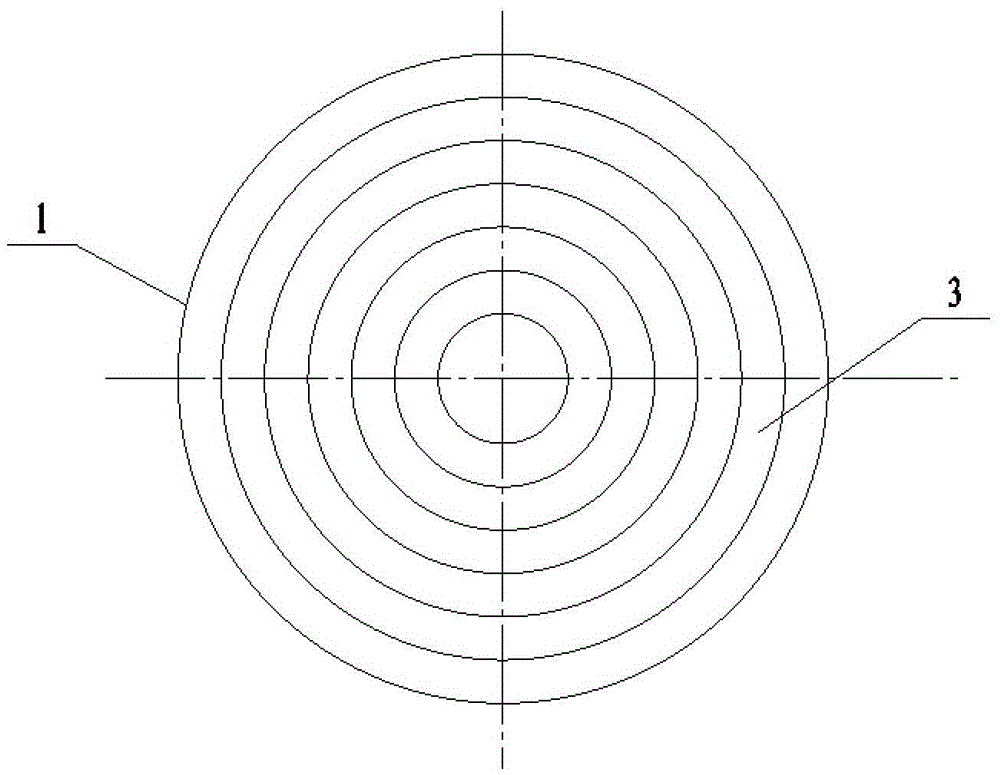

[0033] The rings of the coaxial multi-ring Gaussian mirror are equally spaced, and the width of the rings 3 is T, which is conducive to improving the stability of the lens in different laser modes. Each ring 3 is a spherical ring, and the spherical radius is equal to R0 , another spherical radius is R1. The lens diameter depends on the incident spot size.

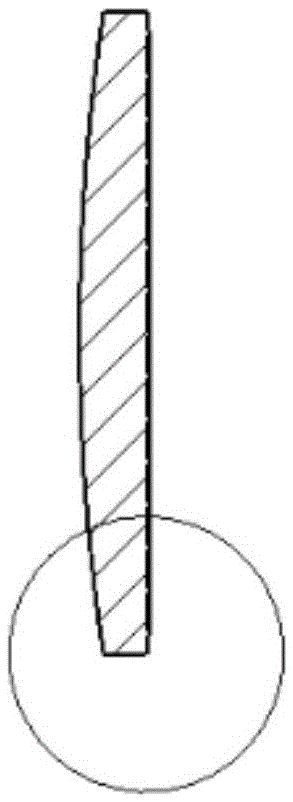

[0034] Such as Figure 6 As shown, taking circular parallel or near-parallel light incidence as an example, D is the total diameter of the focused spot, and BFL1 and BFL2 correspond to the back focal length formed by spherical radius R1, lens thickness, and refractive index in the corresponding assembly mode. Wherein, the focus spot diameter D is proportional to the radius R1 of the spherical surface and the width T of the ring zone, and inversely proportional to the radius of the spherical surface of the ring zone 3, and the theoretical proportional coefficient is about 1. Such as Figure 8 It can be seen that the total...

Embodiment 2

[0036] Since the lens can be assembled front and back, such as Figure 7 As shown, taking circular parallel or near-parallel light incidence as an example, D is the total diameter of the focused spot, and BFL1 and BFL2 correspond to the back focal length formed by spherical radius R1, lens thickness, and refractive index in the corresponding assembly mode. Wherein, the focus spot diameter D is proportional to the radius R1 of the spherical surface and the width T of the ring zone, and inversely proportional to the radius of the spherical surface of the ring zone 3, and the theoretical proportional coefficient is about 1. Depend on Figure 9 The total spot diameter of any cross-section in the focal depth section of the visible lens is D1, and D1 increases with the increase of the defocus distance, and the actual available high power density distribution spot diameter d is basically unchanged. In the focal depth range, there is little difference in the peak power density of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com