Method for one-key turning on/off of chemical engineering equipment

A chemical and control technology, applied in the direction of comprehensive factory control, comprehensive factory control, program control, etc., can solve problems such as nonlinearity, complex start-up and shutdown process, etc., to improve accuracy and timeliness, reduce operation and production risks, realize The effect of intelligent automation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

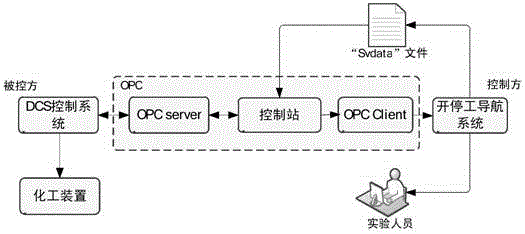

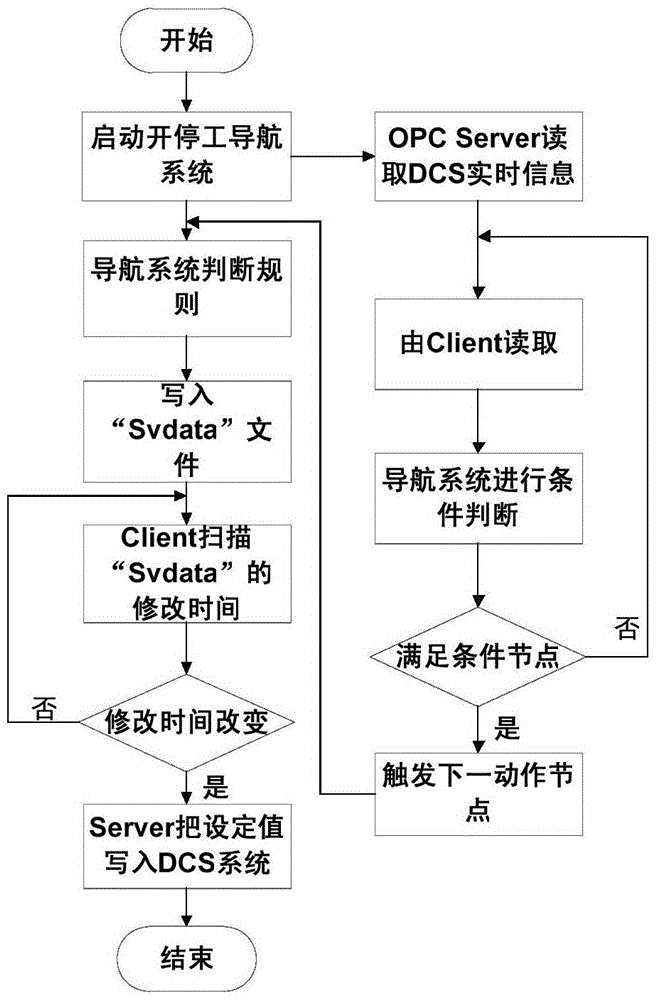

[0031] Such as figure 1 and figure 2 As shown, a method for one-key startup and shutdown of a chemical plant includes a controller, a controlled party, and an OPC interface. Valves in the device, etc., the data scheduling between the start-stop navigation system and the DCS control system realizes data transmission through the OPC interface, and its control steps are as follows:

[0032] (1) Install the start-stop navigation system on a notebook or desktop, and configure OPCClient and OPCServer. The OPCServer collects data for the OPCClient to connect with a standard interface, and connects the start-stop navigation system with the DCS control system through a network cable to ensure that the notebook or desktop The computer and the DCS control system are in the same local area network;

[0033] (2) OPCServer collects real-time data from the DCS control system, and transmits the data to OPCClient, and OPCClient transmits the data to the custom byte position of the control s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com