Device and installation method for precision control of pre-embedded components of push-pull device in nuclear power plant

A push-pull device and precision control technology, which is applied in nuclear power generation, nuclear power plant auxiliary equipment, nuclear engineering, etc., can solve the problems of difficult installation and precision control of push-pull device embedded parts, and achieve the effect of easy flexible operation and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

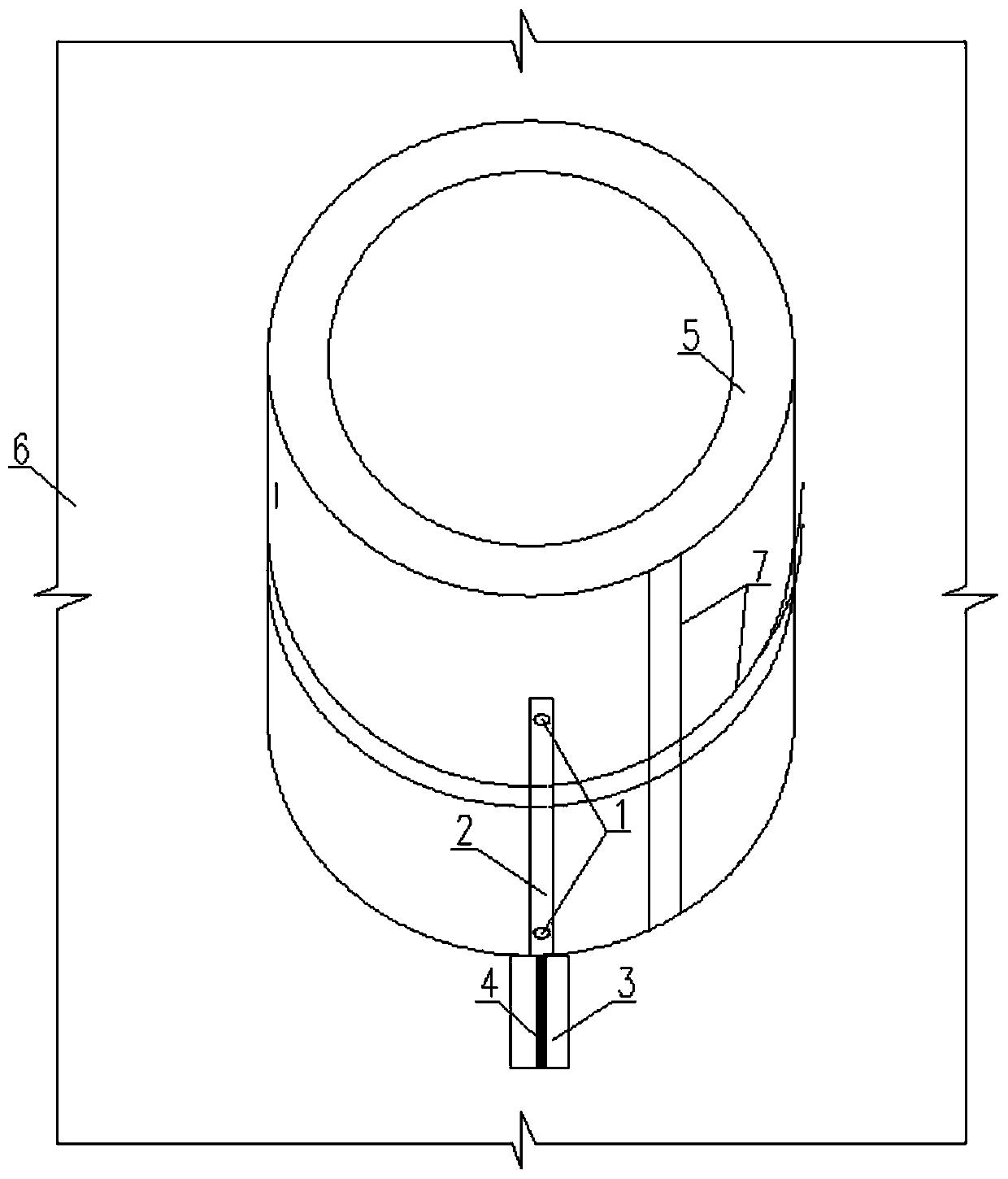

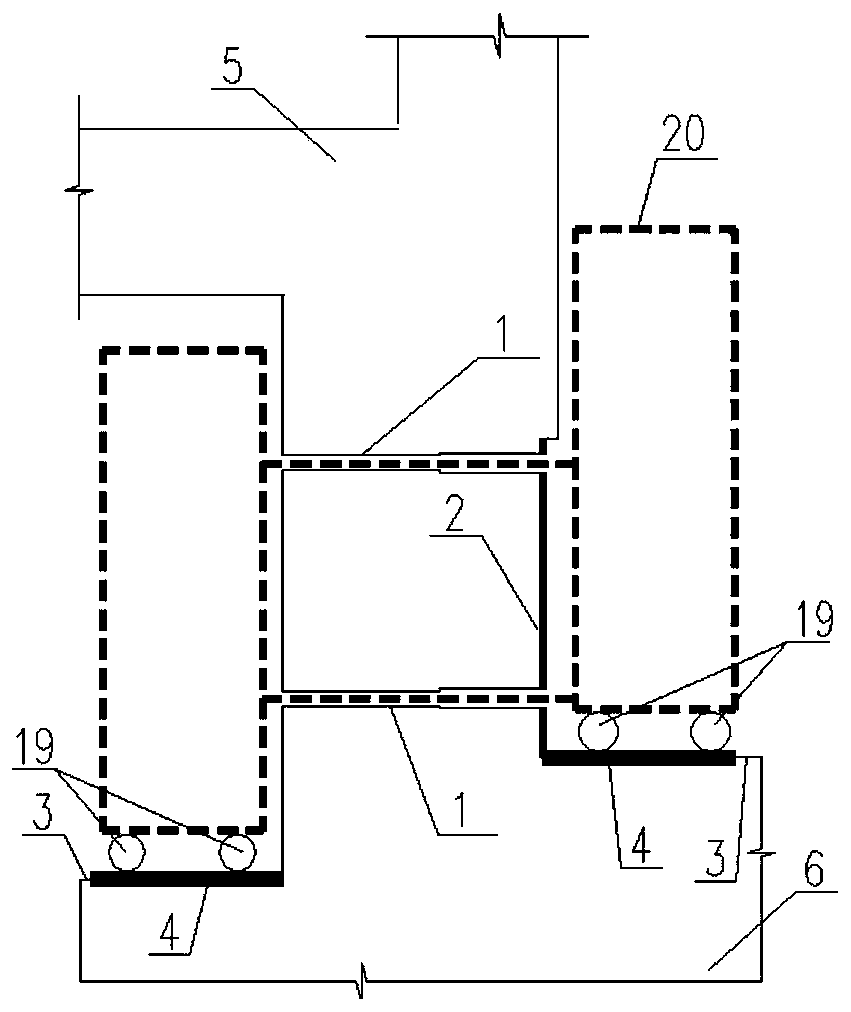

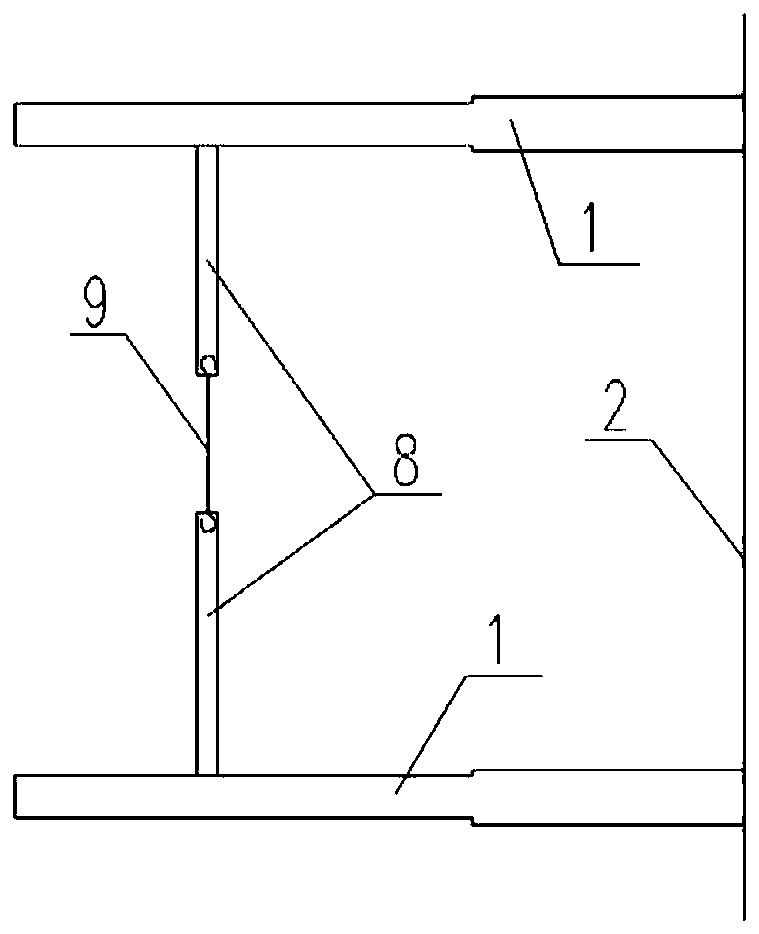

[0017] Attached below Figures 1 to 6 The present invention is further described with examples.

[0018] Step 1: Prefabricate the embedded casing 1 in the factory and weld it with the steel panel 2 to meet the vertical coplanarity of the center line of the casing; weld the angle steel 8 with the blue bolt 9, and weld the angle steel 8 with the angle steel connector 12 to form a detachable Adjust the support; connect the embedded casing and the detachable adjustable support through the hoop 10, and adjust the parallelism of the centerlines of the two embedded casings by adjusting the number of gaskets 11 and the threads of the blue bolts 9 to meet the horizontal parallelism Tolerance requirement ≦1mm, tighten the nut a13.

[0019] Step 2, prefabricate the embedded plate 3 in the factory, and connect the bolts 15 to the embedded plate 3 through perforated plug welding 16 .

[0020] Step 3, install the embedded slab 3 on the peripheral floor 6 on site, and adjust the centerline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com