Graphene transparent electrode, fabrication method thereof and display device

A production method and transparent electrode technology, which is applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of large surface fluctuations and large resistance of transparent electrodes, and achieve the effect of simple production method and high flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

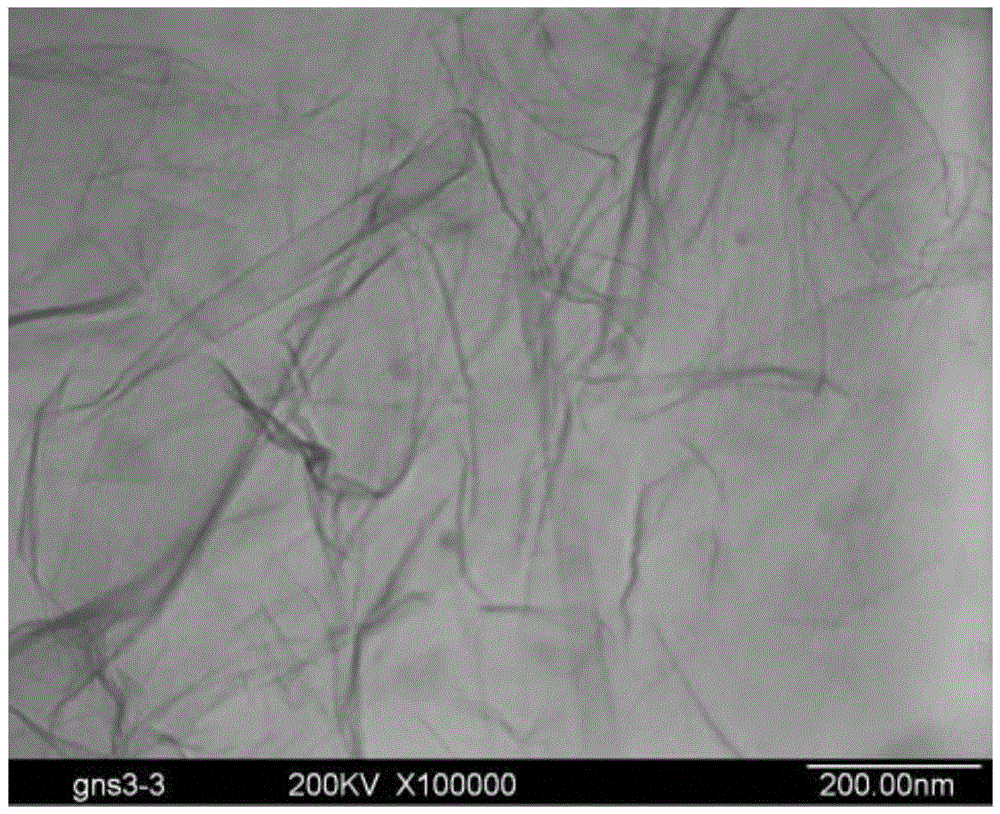

[0031] The specific implementations of the graphene transparent electrode provided by the embodiments of the present invention, its manufacturing method and the display device will be described in detail below with reference to the accompanying drawings.

[0032] Wherein, the size and shape of each structure in the drawings do not reflect the real proportion of the graphene transparent electrode, and the purpose is only to schematically illustrate the content of the present invention.

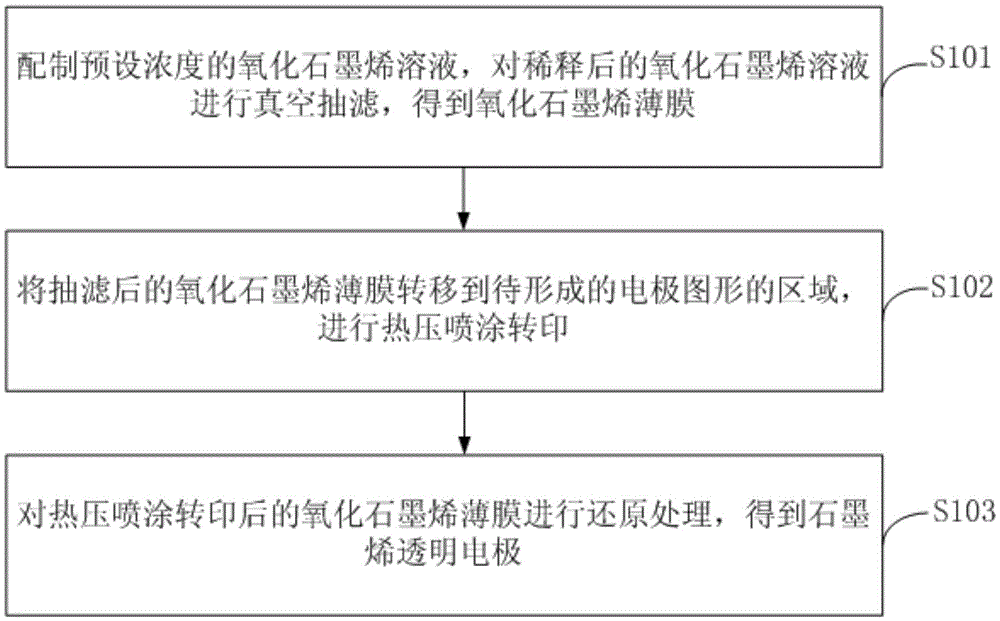

[0033] Embodiments of the present invention provide a method for making a graphene transparent electrode, such as figure 1 shown, including:

[0034] S101. Prepare a graphene oxide solution with a preset concentration, and perform vacuum filtration on the diluted graphene oxide solution to obtain a graphene oxide film;

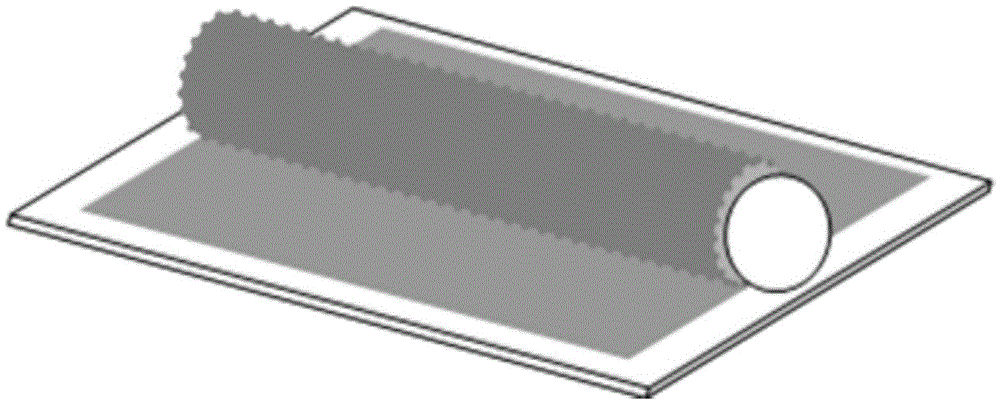

[0035] S102. Transfer the suction-filtered graphene oxide film to the area of the electrode pattern to be formed, and perform hot-press spraying transfer printing;

[0036]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com