Improved light emitting diode (LED) package structure

A technology of LED packaging and sealing sleeves, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as poor waterproof performance and sealing performance, user loss, luminous efficiency, low power consumption, low response speed, etc., to extend service life. , Prevent damage and scrap, and the effect of LED package structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

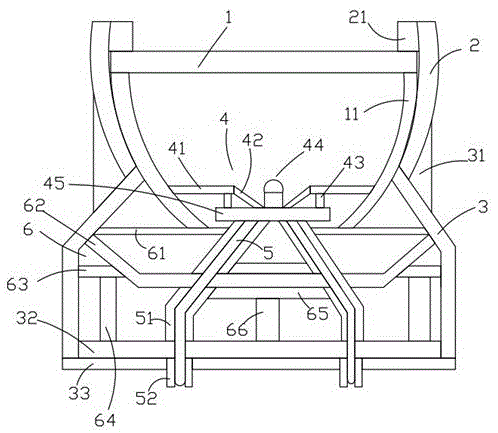

[0019] like figure 1 As shown, the improved LED packaging structure of the present invention includes a transparent plate 1, an upper case 2 located outside the transparent plate 1, a lower case 3 located below the upper case 2, a light emitting device 4 located inside, and a The conductive rod 5 below the light emitting device 4 and the fixing device 6 arranged inside the lower casing 3 .

[0020] like figure 1 As shown, the transparent plate 1 is a cylinder, the transparent plate 1 is placed horizontally, the transparent plate 1 is made of transparent material, and the transparent plate 1 is provided with a reflection bucket 11 located below, and the reflection bucket 11 is hemispherical, and the inner surface of the reflective bucket 11 is provided with a reflective layer, which can reflect light.

[0021] like figure 1 As shown, the upper casing 2 is ring-shaped, the outer surface of the reflection bucket 11 is fixedly connected with the inner surface of the upper casin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com