Betel nut fiber pillow core and preparation method thereof

A technology of betel nut and fiber, which is applied in the field of betel nut fiber pillow and its preparation, can solve the problems of pillow core that have not been reported yet, and achieve the effects of benefiting sleep, avoiding damage, and rationally utilizing resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

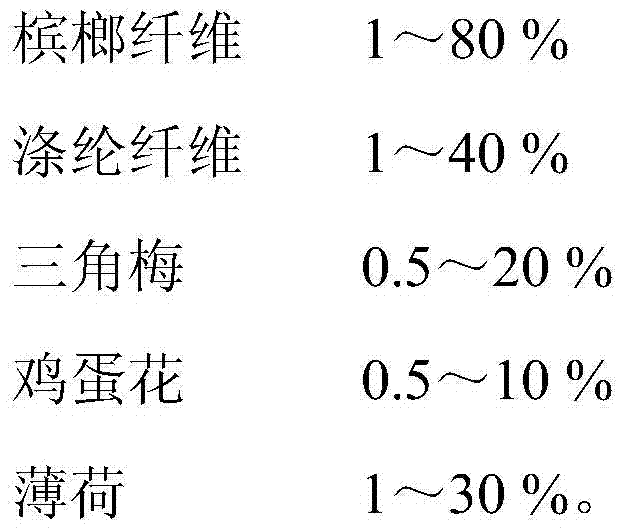

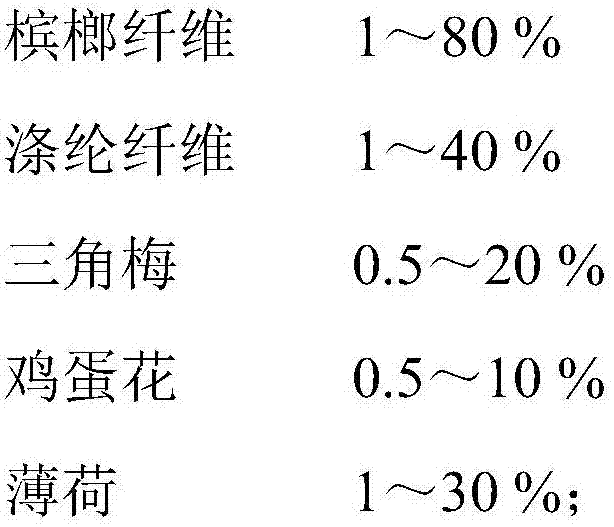

[0024] A kind of betel nut fiber pillow, its preparation steps are as follows:

[0025] (1) Raw material processing: remove impurities from betel nut fiber and polyester fiber and wash them; remove long-stalked branches and leaves and impurities after picking bougainvillea and frangipani; remove impurities from mint and wash;

[0026] (2) Drying: Sterilize, dry or air-dry the various raw materials prepared above until the water content is ≤4% for later use, the drying temperature is 70°C, and the drying time is 20 minutes;

[0027] (3) Crushing: smash or grind the sterilized and dried raw materials in step (2), pass through a 10-mesh sieve, and set aside;

[0028] (4) Filling material preparation: pour 75kg of crushed betel nut fiber, 5kg of polyester fiber, 5kg of bougainvillea, 5kg of frangipani, and 10kg of mint into the stacker, and pour it into the turnover box for distribution after being evenly stirred;

[0029] (5) Bagging and sewing: The filling material mixed in ste...

Embodiment 2

[0031] A kind of betel nut fiber pillow, its preparation steps are as follows:

[0032] (1) Raw material processing: remove impurities from betel nut fiber and polyester fiber and wash them; remove long-stalked branches and leaves and impurities after picking bougainvillea and frangipani; remove impurities from mint and wash;

[0033] (2) Drying: Sterilize, dry or air-dry the various raw materials prepared above until the water content is ≤4% for later use. Drying temperature 80°C, time 30 minutes;

[0034] (3) Crushing: crush or grind the sterilized and dried raw materials in step (2) into granules, pass through a 40-mesh sieve, and set aside;

[0035] (4) Filling preparation: pour 55kg of betel nut fiber, 30kg of polyester fiber, 5kg of bougainvillea, 5kg of frangipani, and 5kg of mint into the stacking machine after being evenly stirred, and then pour into the turnover box for distribution;

[0036] (5) Bagging and sewing: The filling material mixed in step (4) is re-drie...

Embodiment 3

[0038] A kind of betel nut fiber pillow, its preparation steps are as follows:

[0039] (1) Raw material processing: remove impurities from betel nut fiber and polyester fiber and wash them; remove long-stalked branches and leaves and impurities after picking bougainvillea and frangipani; remove impurities from mint and wash;

[0040] (2) Drying: Sterilize, dry or air-dry the various raw materials prepared above until the water content is ≤4% for later use; the drying temperature is 100°C, and the time is 40 minutes;

[0041] (3) Crushing: smash or grind the sterilized and dried raw materials in step (2) into granules, pass through an 80-mesh sieve, and set aside;

[0042] (4) Filling material preparation: pour 40kg of crushed betel nut fiber, 20kg of polyester fiber, 10kg of bougainvillea, 5kg of frangipani, and 25kg of mint into the stacker, and pour it into the turnover box for distribution after being evenly stirred;

[0043] (5) Bagging and sewing: The filling material m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com