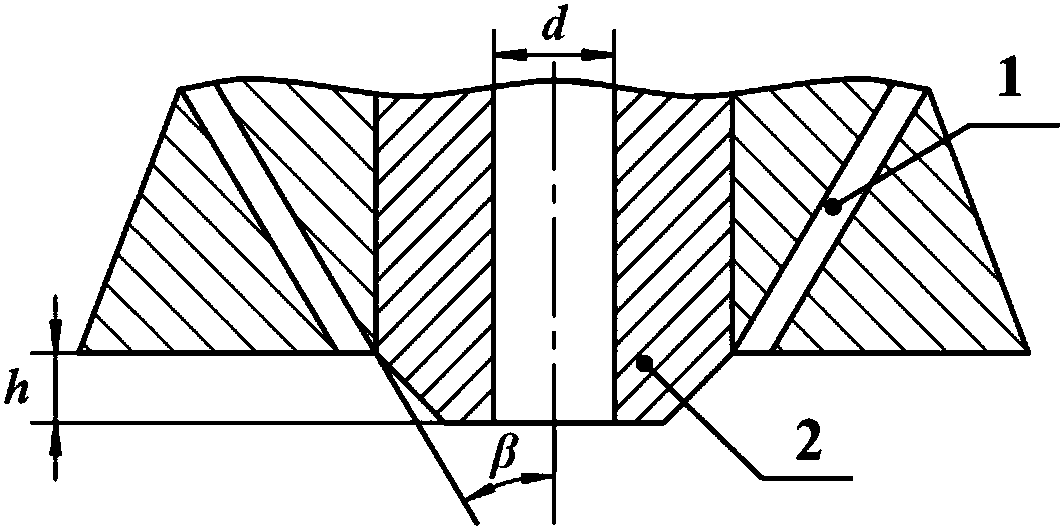

A Supersonic Atomizing Nozzle with Adjustable Structural Parameters

A technology for atomizing nozzles and structural parameters, which is applied in the field of supersonic atomizing nozzles, can solve the problems of flexible adjustment of the protruding length of the gas mass flow diversion pipes with difficult structures, reducing the versatility of atomizing nozzles, etc., so as to prevent pollution and improve the universality. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

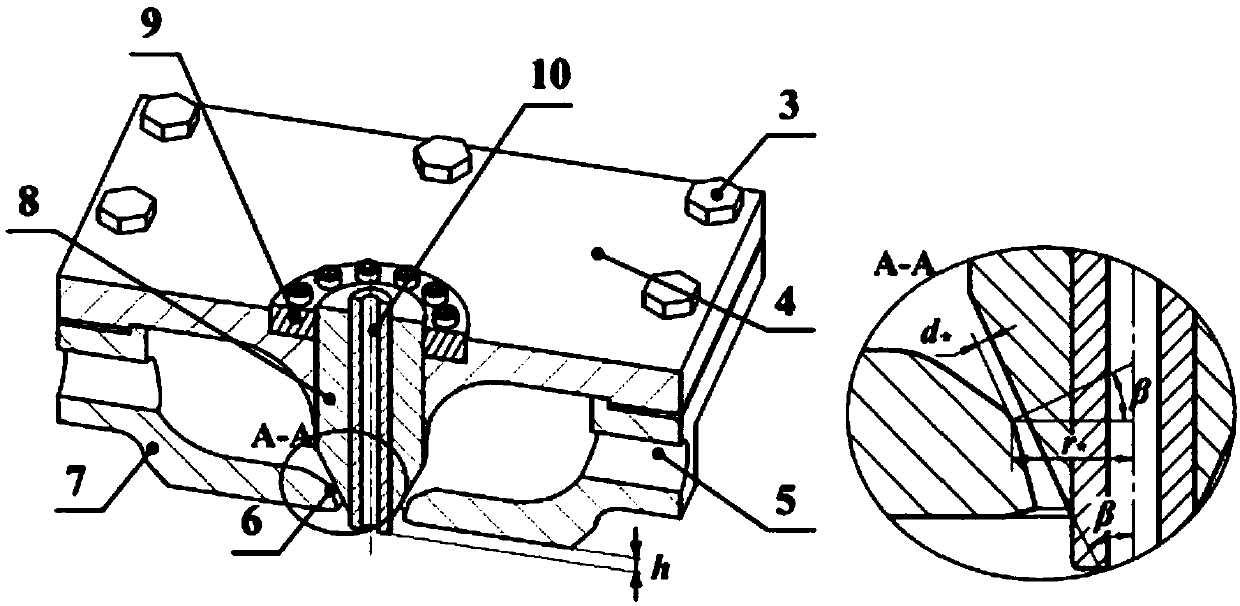

[0029] Taking the atomization of the 7055 alloy by the flexible supersonic atomizing nozzle involved in the present invention as an example, the specific embodiments of the present invention are as follows:

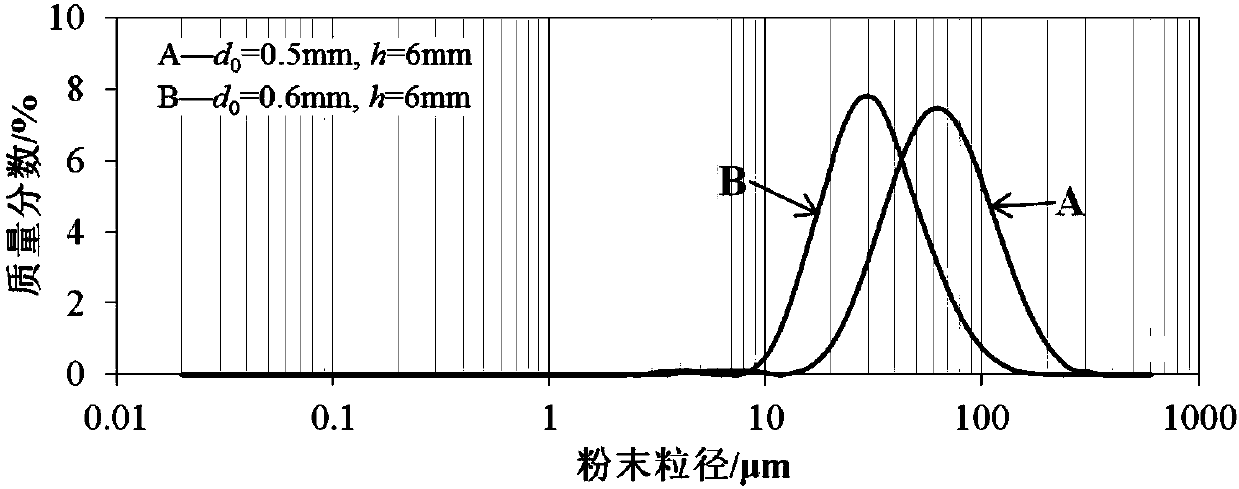

[0030] (1) Adjust the structural parameters of the nozzle, select the protruding length of the draft tube h = 6mm, and the width of the air outlet d 0 =0.5mm;

[0031] (2) Melting the 7055 parent alloy to 800°C in a vacuum or inert gas protection atmosphere;

[0032] (3) The molten metal melt enters the high-speed gas atomization zone through the guide tube 10, and the atomization argon gas supply device is opened at the same time, and the molten 7055 alloy is atomized when the atomization pressure is 0.8MPa;

[0033] (4) Collect the metal powder after the atomization is completed, and select the test sample A;

[0034] (5) Readjust the structural parameters of the nozzle and select the width d of the air outlet 0 =0.6mm, repeat steps (2)~(4) to obtain test sample B; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com