Convenient transition clamp of magnetic worktable

A workbench, convenient technology, applied in the direction of manufacturing tools, clamping, electric machining equipment, etc., can solve the problems of low efficiency, high cost, material waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

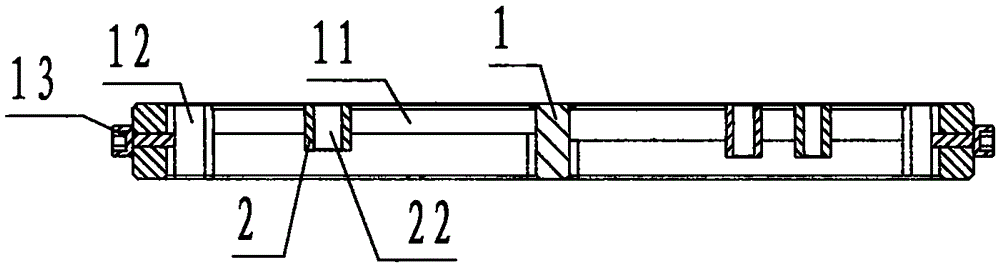

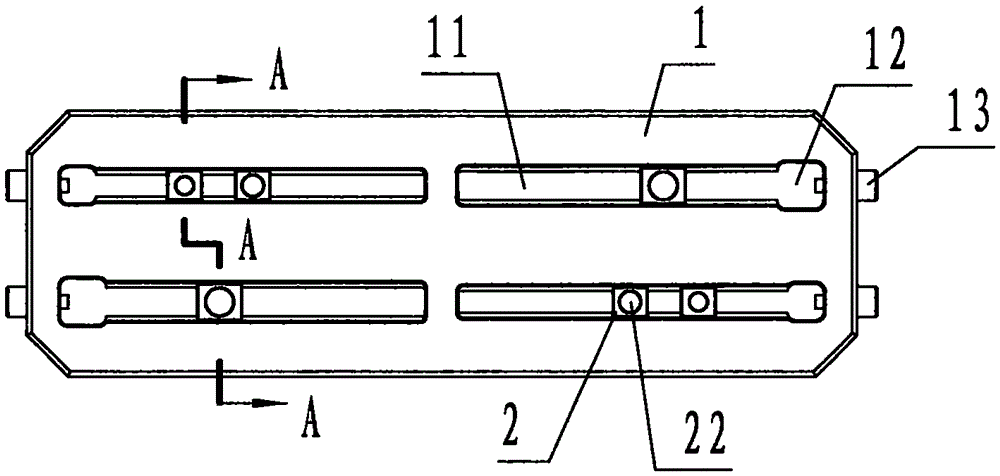

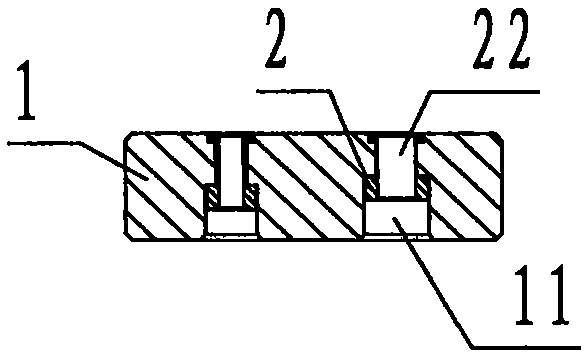

[0022] refer to Figure 1 to Figure 8 , a convenient transition fixture for a magnetic workbench of the present invention includes a base 1 and an I-shaped slider 2, wherein: the base 1 is a steel member in the shape of a rectangular plate, and the base 1 is equipped with four The cross-section is I-shaped, and it is a long rectangular through hole in the left and right directions when viewed from above. The through hole is called I-shaped rail 11; each of the I-shaped rails 11 is located at one end corresponding to the left or right side of the base 1 A rectangular reaming hole with a side length greater than the front and rear side width of the I-shaped rail 11 is provided and is called a block hole 12; the left and right sides of the base 1 are respectively provided with plug screws 13 corresponding to the block hole 12;

[0023] The I-shaped slider 2 is a block-shaped steel member with an I-shaped cross-section and a rectangular shape when viewed from above. The groove 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com