Movable sand blowing polishing machine achievement method

A realization method, polishing machine technology, applied in grinding/polishing equipment, non-mechanical abrasive jet generation equipment, explosion generation devices, etc., can solve the problems of easy blocking of sandblasting pipes, etc., to reduce wear, The effect of reducing work intensity and increasing effective power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

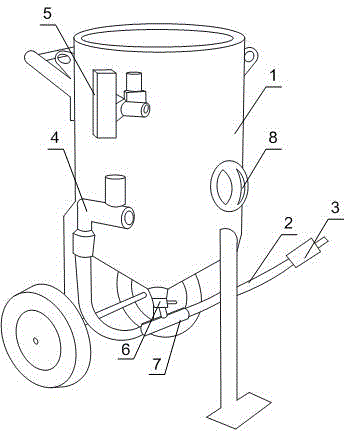

[0019] like figure 1 As shown, this embodiment includes a box body 1, a sandblasting pipe 2 and a nozzle 3, the box body 1 is provided with an air intake control valve 4 and an exhaust control valve 5, and the sand outlet at the bottom of the box body 1 is installed with a Butterfly sand control valve 6, one end of sandblasting pipe 2 is connected to box body 1 through air intake control valve 4, and the other end is connected to butterfly sand control valve 6 and nozzle 3 respectively through thickened sand outlet tee 7, and also includes The two casters and the supporting feet arranged on the bottom of the box body 1 are distributed in a triangular shape. According to the stability of the triangle, the combination of casters and feet can provide stable support and fixation during the polishing process; when moving, just tilt one end of the cabinet 1 and push the cabinet 1, and the casters can roll Quickly move the sandblasting machine, reducing the work intensity of workers...

Embodiment 2

[0022] like figure 1 As shown, on the basis of Embodiment 1, this embodiment also includes an observation port 8 arranged in the middle of the box body 1 , and tempered glass is installed on the observation port 8 . An observation port 8 is set in the middle and lower part of the box body 1, which can be used by the operator to check the remaining amount of abrasive at any time, which is convenient for adding abrasive in time to ensure sandblasting efficiency; the installation of high-strength tempered glass can avoid abrasive Continuous impact on the observation port 8 will cause the glass to break.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com