An all-in-one machine for degassing, capping, and leveling for automatic production of magnesite bricks

An automatic production and integrated machine technology, applied in ceramic molding machines, ceramic molding workshops, auxiliary molding equipment, etc., can solve the problems of inability to realize the automatic production requirements of magnesite bricks, complex structure, etc., to reduce personnel costs and equipment costs, The effect of high work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings. It is only stated here that the words for directions such as up, down, left, right, front, back, inside, and outside that appear or will appear in the text of the present invention are only based on the accompanying drawings of the present invention, and are not specific to the present invention. limited.

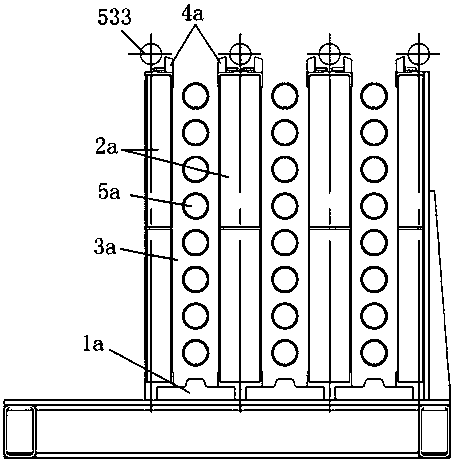

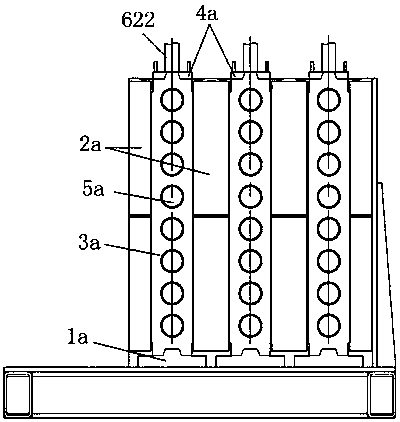

[0031] It should be noted that the mold structure diagram of the automatic production line of magnesite bricks is as attached figure 1 And attached figure 2 Shown, comprise bottom mold 1a, side mold 2a, mold cavity 3a, adjacent side mold 2a forms mold cavity 3a, the top of mold cavity is an open structure, by setting upper cover 4a on the top of side mold to form mold The cavity 3a is covered, and one mold cavity 3a is provided with corresponding left and righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com