Aluminum alloy decorative panel with glass-like effect

A decorative panel and glass effect technology, applied in special decorative structures, decorative arts, metal layered products, etc., can solve the problems of falling off, not environmentally friendly, easy to wear patterns, etc., to achieve full color, prevent yellowing, and strong three-dimensional effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

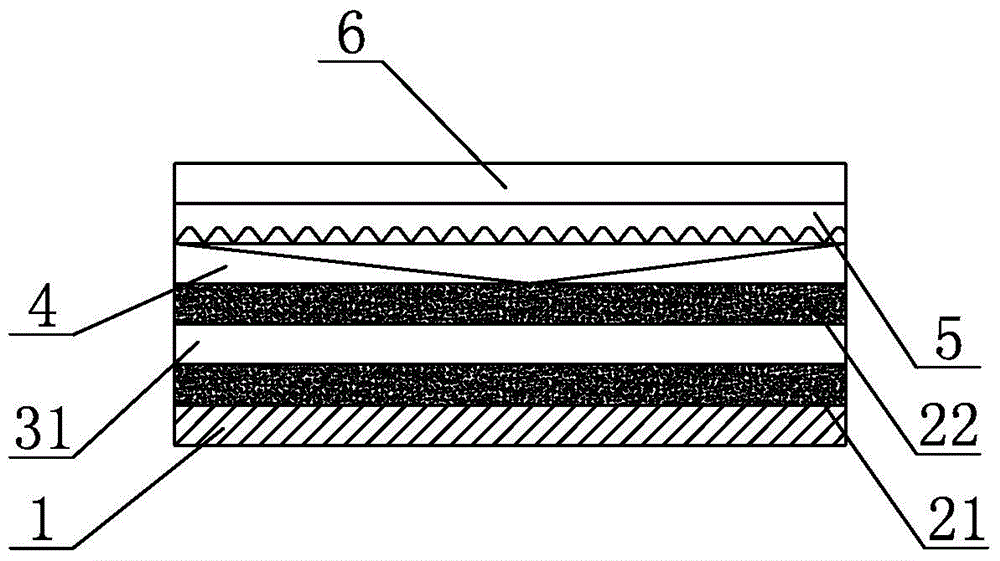

[0029] Such as figure 1 As shown, an aluminum alloy decorative panel with imitation glass effect includes an aluminum alloy substrate 1, an intermediate layer, a color layer 31, a texture layer 4, a brightening layer 5 and a hardened resin layer 6; the aluminum alloy substrate is surface cleaned Afterwards, the intermediate layer one 21 is coated on its surface and dried, and the color layer is coated on the surface of the intermediate layer one and dried, and the surface of the color layer is coated with the intermediate layer two 22, and the intermediate layer After the two surfaces are coated with a texture layer, the texture is embossed with a mold, the surface of the texture layer is coated with the brightness-enhancing layer, and the brightness-enhancing layer is externally coated with the hardened resin layer; the middle layer 1 and middle layer 2 Both are epoxy resin layers; the texture of the texture layer is a texture structure designed according to needs; the surfac...

Embodiment 2

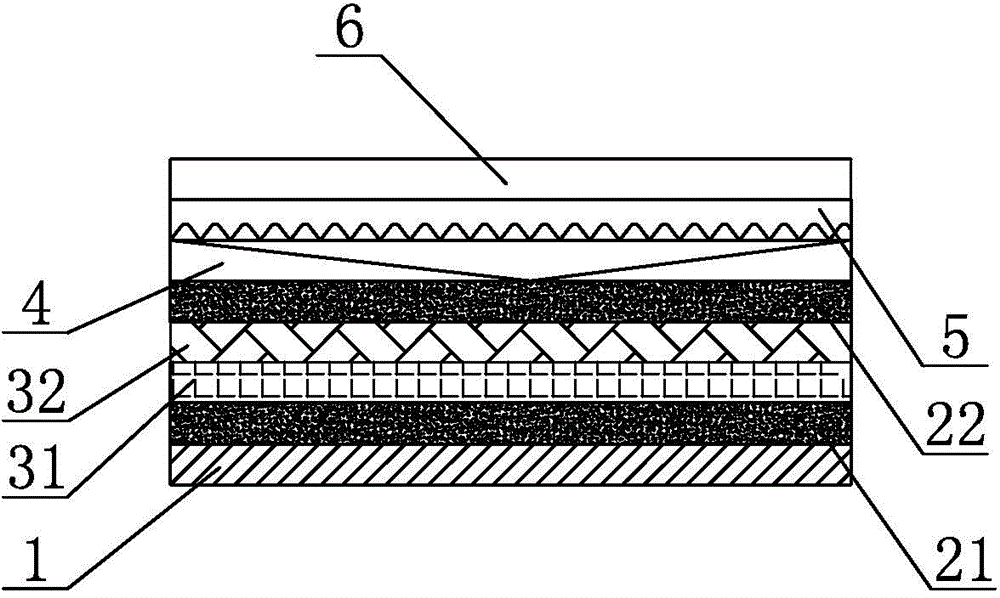

[0031] Such as figure 2 As shown, an aluminum alloy decorative panel with imitation glass effect includes an aluminum alloy substrate 1, an intermediate layer, a color layer 31, a texture layer 4, a brightening layer 5 and a hardened resin layer 6; the aluminum alloy substrate is surface cleaned Afterwards, the intermediate layer one 21 is coated on its surface and dried, and the color layer is coated on the surface of the intermediate layer one and dried, and the surface of the color layer is coated with the intermediate layer two 22, and the intermediate layer After the two surfaces are coated with a texture layer, the texture is embossed with a mold, the surface of the texture layer is coated with the brightness-enhancing layer, and the brightness-enhancing layer is externally coated with the hardened resin layer; the middle layer one and the middle layer two Both are epoxy resin layers; the texture of the texture layer is the texture structure of radiation; the surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com