Rumex hanus plant protein tea and making process thereof

A technology of plant protein and production process, which is applied in the field of leaf-eating herb plant protein tea, can solve the problems of large gap between the outer dryness and inner humidity of tea leaves, dry and cracked tea skin, and affect the quality of leaf-eating herb tea, so as to improve the quality and fully dry the tea Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

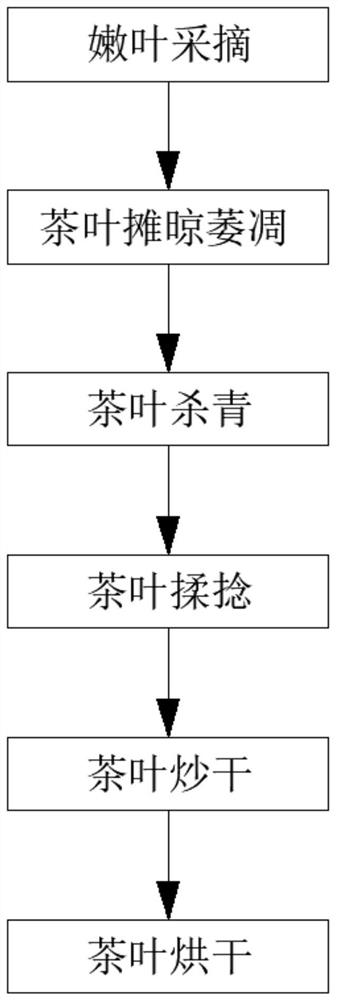

[0026] see figure 1 , The present invention provides a technical scheme: a leaf-eating herbal vegetable protein tea, including the leaf-eating herb.

[0027] In addition, the present invention also provides a process for making leaf-eating herbal vegetable protein tea, comprising the following steps:

[0028] S1. Picking of tender leaves: After picking the leaf buds of the leaf-eating grass, pick out the petals, incomplete leaf buds and yellow leaves, wash the tea leaves, put the leaf buds into a cleaning tank, and use the sprayer and water pump to dilute the The barley enzyme cleaning agent is sprayed into the cleaning tank, and the leaf buds in the cleaning tank are cleaned. The temperature in the cleaning tank is kept at 15-20 degrees Celsius, and the activity of the barley enzyme is maintained. The activity concentration of the barley enzyme is 0.1 -0.25u / ml, after the cleaning agent is injected into the cleaning tank, soak the leaf buds of the leaf-eating grass in the cl...

Embodiment 2

[0035] For the sake of simplicity, only the points of difference from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is:

[0036] In S3, the withered tea leaves are placed in the greening machine, and the tea leaves are preheated at a temperature of 220 degrees Celsius for 5 minutes, then heated to 300 degrees Celsius, and the greening time is 8 minutes, and the water in the tea leaves is extracted. After completion, the drum used for fixing continues to rotate, and when the tea leaves are naturally cooled to 60-70 degrees Celsius, the tea leaves are subjected to high temperature fixing, and the temperature is 400 degrees Celsius, and the tea leaves are subjected to secondary fixing;

[0037] In S4, the cooled green leaves are sent into the mechanical rolling machine. The rotating speed of the rolling machine in the early stage is 35r / min. After rolling for 6 minutes, the speed increases slowly until it increases to 70r / min. Aft...

Embodiment 3

[0039] The difference between this embodiment 3 and embodiment 2 is:

[0040] In S3, the withered tea leaves are placed in the green-fixing machine, and the tea leaves are preheated at a temperature of 220 degrees Celsius for 8 minutes, then heated to 270 degrees Celsius, and the greening time is 10 minutes, and the water in the tea leaves is extracted. After completion, the drum used for fixing continues to rotate, and when the tea leaves are naturally cooled to 60-70 degrees Celsius, the tea leaves are subjected to high temperature fixing, and the temperature is 350 degrees Celsius, and the tea leaves are subjected to secondary fixing;

[0041] In S4, the cooled green leaves are sent into the mechanical rolling machine. The rotating speed of the rolling machine in the early stage is 40 r / min. After rolling for 5 minutes, the speed increases slowly until it increases to 75 r / min. After rolling for 2 hours, the tea leaves in the mechanical rolling machine are naturally cooled f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com