Underwater electric steering engine and rudder angle detection method

A technology of electric steering gear and rudder angle, which is applied in the direction of rudder steering, measuring device, and electric device, etc., which can solve the problem that autonomous underwater robots cannot meet the navigation requirements, the pressure bearing capacity requirements also rise sharply, and the shell cannot provide Sufficient positive buoyancy and other issues to achieve the effect of simple rudder angle detection method, compact structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

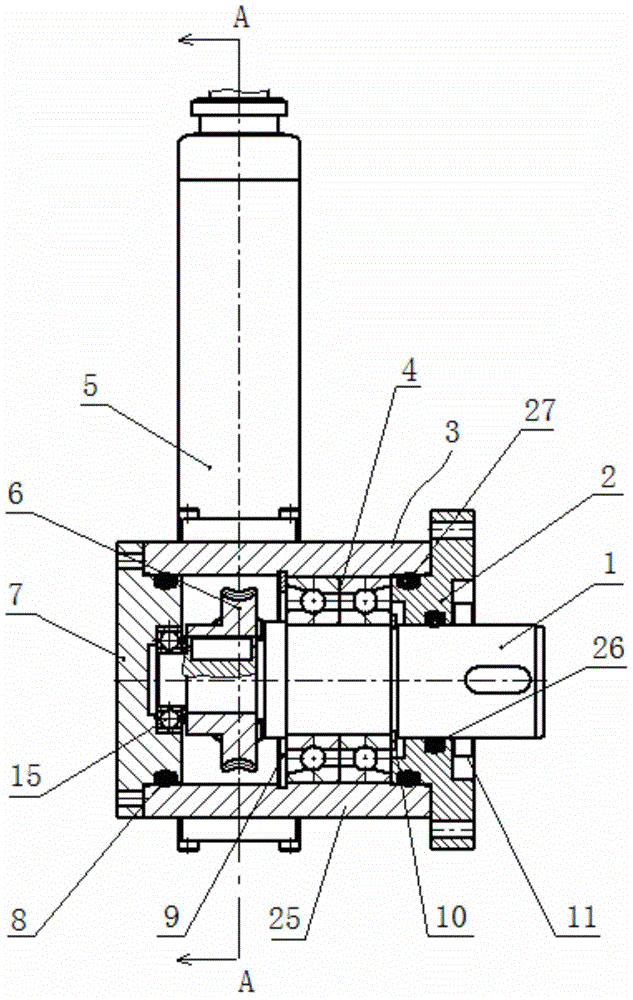

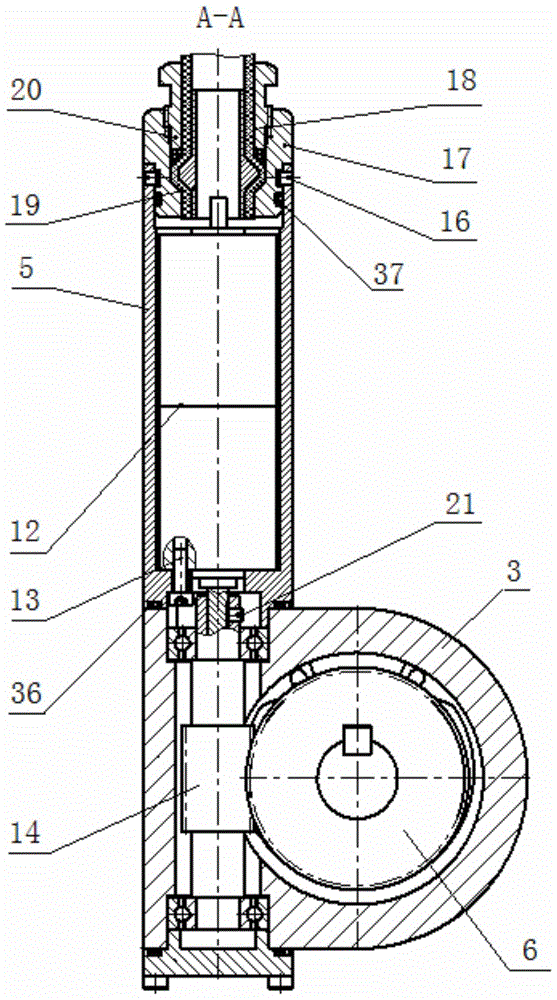

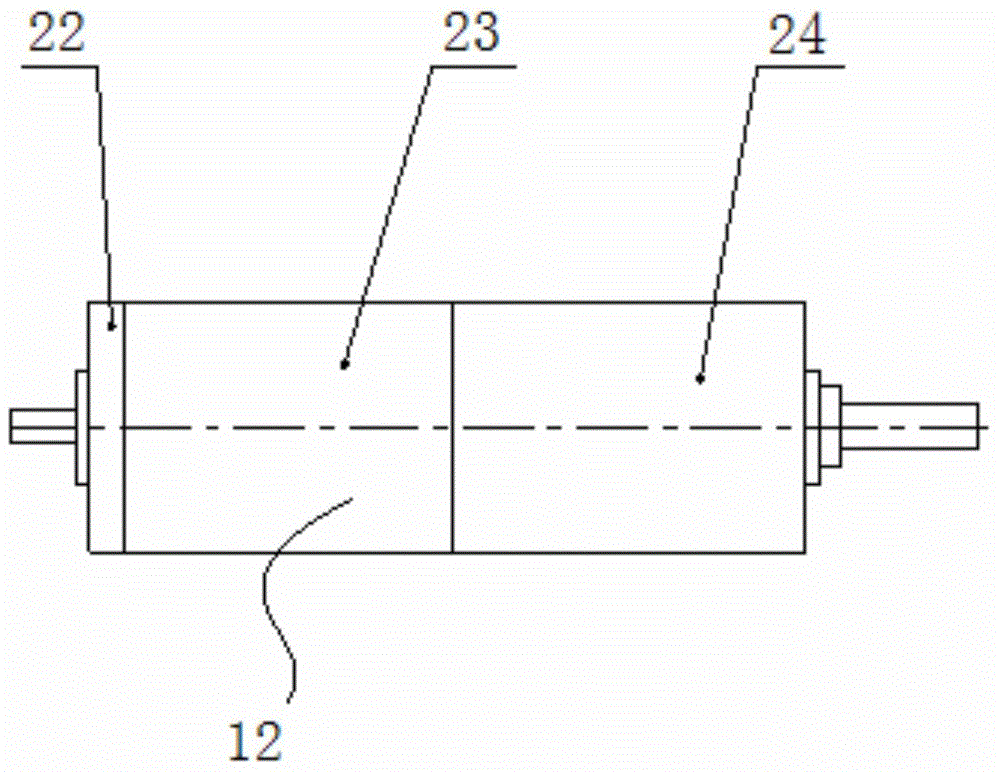

[0028] Such as Figure 1~2 As shown, the present invention includes output shaft 1, machine base 3, worm gear 6, worm screw 14, power system 12 and steering gear controller, wherein the two ends of seat body 25 of said machine base 3 are respectively provided with side end cover 7 and shaft The end cover 2, the output shaft 1, the worm wheel 6 and the worm 14 are all arranged in the base 3, as figure 1 As shown, the output shaft 1 is supported and installed in the machine base 3 through the first bearing 4 and the second bearing 15, and the output shaft 1 protrudes from the end of the machine base 3 provided with the shaft end cover 2, and the first A bearing 4 is arranged in the seat body 25 of the machine base 3 and axially positioned in the middle of the output shaft 1 through a circlip 9 for a hole, a circlip 10 for a shaft and the shaft end cover 2, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com