Distributed carbon fiber reinforcement, preparation method and strain determination method

A determination method, carbon fiber technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve the problems of difficult to measure the stress state of carbon fiber reinforcement, high price of optical fiber, poor stability, etc., to achieve simple and reliable measurement principle, production Simple process, good corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

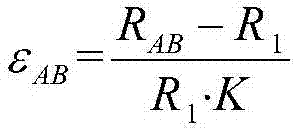

Examples

Embodiment 1

[0075] A method for manufacturing a distributed carbon fiber tendon sensor with self-sensing characteristics, comprising the following steps:

[0076] (1) Stir 60 parts by weight of E51 epoxy resin, 20 parts by weight of curing agent 591, 60 parts by weight of carbon powder, and 20 parts by weight of diluent acetone at a normal temperature of 10°C-40°C to obtain a mixture A;

[0077] (2) Soak the carbon fiber in the mixture A along the wire, and take out the carbon fiber after fully soaking;

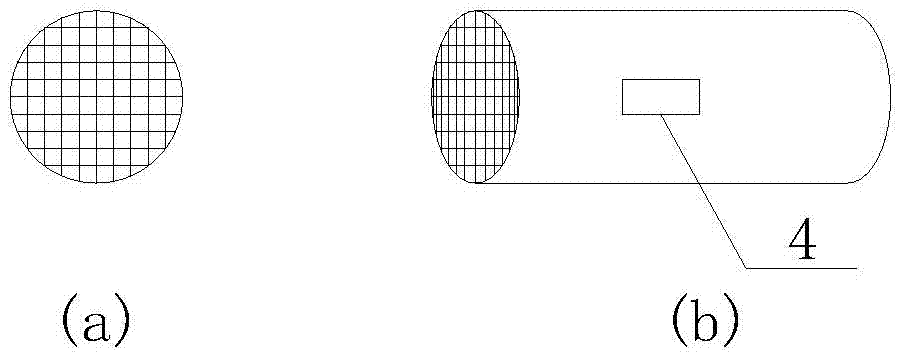

[0078] (3) Control the number of carbon fiber monofilaments in each bar, and filter out excess carbon fiber glue;

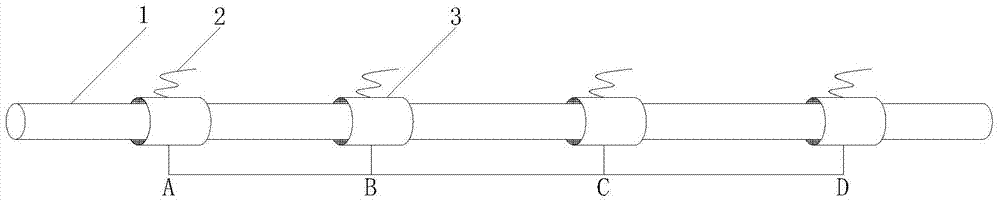

[0079] (4) Make the carbon fiber filament radially pass through a copper sleeve at intervals along the radial direction of the carbon fiber reinforcement, and lead out the surface electrodes of the copper sleeve with wires;

[0080] (5) Apply a release agent in the pre-prepared mold to facilitate subsequent demoulding;

[0081] (6) Place the carbon fiber reinforcement in ...

Embodiment 2

[0091] A method for manufacturing a distributed carbon fiber tendon sensor with self-sensing characteristics, comprising the following steps:

[0092] (1) Stir 60 parts by weight of E44 epoxy resin, 20 parts by weight of polyamide 650 curing agent, 60 parts by weight of carbon powder, and 20 parts by weight of diluent acetone at a normal temperature of 10°C-40°C to obtain a mixture A ;

[0093] (2) Soak the carbon fiber in the mixture A along the wire, and take out the carbon fiber after fully soaking;

[0094] (3) Control the number of carbon fiber monofilaments in each bar, and filter out excess carbon fiber glue;

[0095] (4) Make the carbon fiber filament radially pass through a copper sleeve at intervals along the radial direction of the carbon fiber reinforcement, and lead out the surface electrodes of the copper sleeve with wires;

[0096] (5) Apply a release agent in the pre-prepared mold to facilitate subsequent demoulding;

[0097] (6) Place the carbon fiber reinf...

Embodiment 3

[0107] A method for manufacturing a distributed carbon fiber tendon sensor with self-sensing characteristics, comprising the following steps:

[0108] (1) Stir 60 parts by weight of E51 epoxy resin, 20 parts by weight of curing agent 591, 60 parts by weight of copper powder, and 20 parts by weight of diluent acetone at a normal temperature of 10°C-40°C to obtain a mixture A;

[0109] (2) Soak the carbon fiber in the mixture A along the wire, and take out the carbon fiber after fully soaking;

[0110] (3) Control the number of carbon fiber monofilaments in each bar, and filter out excess carbon fiber glue;

[0111] (4) Make the carbon fiber filament radially pass through a copper sleeve at intervals along the radial direction of the carbon fiber reinforcement, and lead out the surface electrodes of the copper sleeve with wires;

[0112] (5) Apply a release agent in the pre-prepared mold to facilitate subsequent demoulding;

[0113] (6) Place the carbon fiber reinforcement in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com