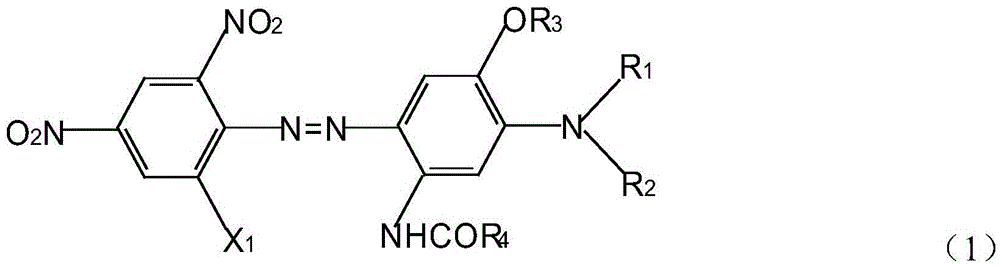

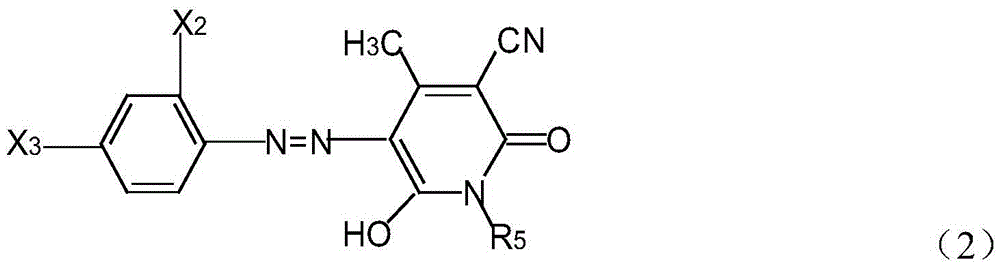

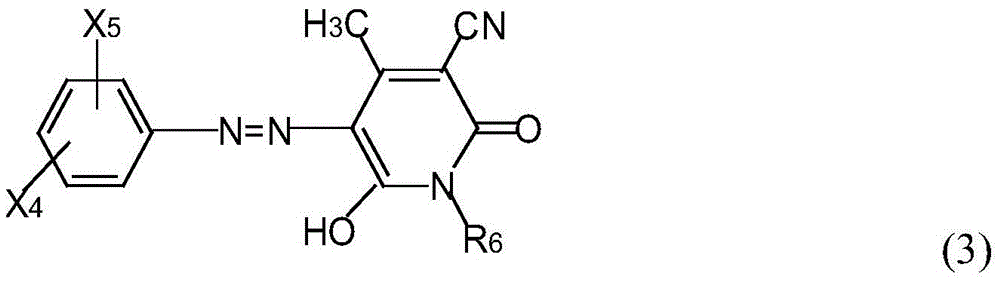

Disperse dye combination, disperse dye and preparation method and application thereof

A technology of disperse dyes and compositions, which is applied in dyeing methods, organic dyes, textiles and papermaking, etc. It can solve the problems of heavy staining of spandex, inability to dye and print polyester-spandex and polyester-cotton blended fabrics, and achieve high cost performance, Good washing fastness, light fastness and perspiration fastness have obvious advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] With 58 grams of component A of formula (1-1), 13.9 grams of formula (2-2) component B, 9.4 grams of component C shown in formula (3-4), 5.6 grams of formula (4-1 ) shown in Component D, 13.1 grams of Component E shown in formula (5) and 130 grams of imported lignin 85A, after adding 390 grams of water and blending, grinding with a sand mill, spray drying and making disperse dyes.

Embodiment 2

[0091] With 54 grams of component A of formula (1-2), 10 grams of formula (2-2) component B, 8 grams of component C shown in formula (3-2), 10 grams of formula (4-1 ) shown in component D, 18 grams of component E shown in formula (5) and 120 grams of diffusing agent CNF, after adding 390 grams of water and blending, grinding with a sand mill, spray drying to make disperse dyes.

Embodiment 3-14

[0102] According to the same method of embodiment 1, according to the composition formula in table 3, blue disperse dyes are made as shown in table 3.

[0103] Table 3 Weight unit: grams

[0104]

[0105]

[0106] The dyestuffs of Examples 3-14 were subjected to performance tests respectively.

[0107] The specific test method is as follows:

[0108] With reference to the method of GB / T2394-2006, take by weighing 0.5 gram of the disperse dye that embodiment 3-14 makes respectively in the 500ml volumetric flask, make disperse dye suspension, draw 60ml disperse dye suspension and mix with the water of 40ml, use Adjust the pH of the dyeing bath to 5 with acetic acid, and then raise the temperature to 60°C. 2g of polyester-spandex blended fabric is dyed under high temperature and high pressure. The temperature is raised to 130°C within 35 minutes, kept for 45 minutes, and cooled to 80°C for sampling.

[0109] Observe the color light of the cloth samples and measure their s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com