Method for reducing fiber hairiness of polytetrafluoroethylene membrane cracks

A technology of polytetrafluoroethylene film and fiber, which is applied in the direction of suction liquid/gas/vapour removal, textile and papermaking, fabric surface trimming, etc. Problems such as large pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

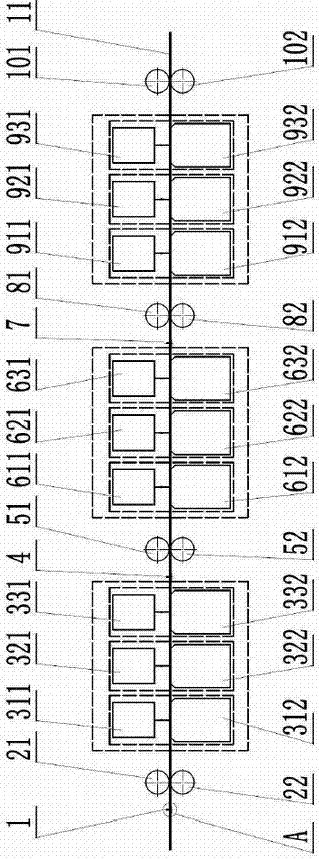

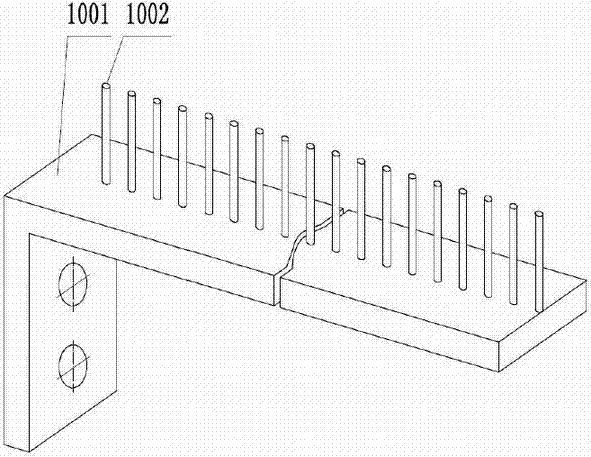

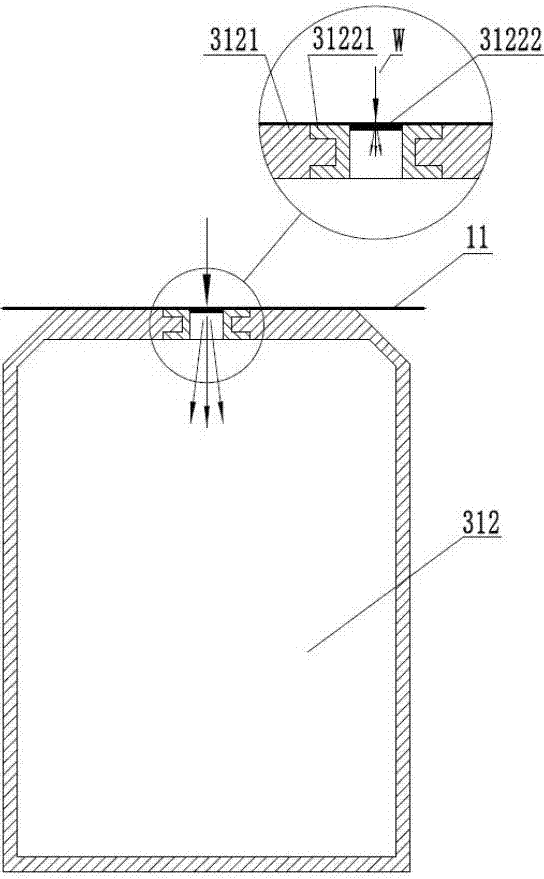

[0071] The polytetrafluoroethylene film-split fiber tow with a linear density of 2000 denier and a number of hairiness per unit length of 48 produced by the conventional film-split method is used as the primary tow, and then 50 of them are flattened into a layer with a width of 250 mm. 1. The tow layer with a thickness of 1.5 mm is regularly arranged after being combed by the comb needles 1002 of the first comb part 1, and fed into the first horizontal layer with three spunlace head parts through the first pair of rubber feeding roller parts. Type spunlace unit performs the first horizontal spunlace impact dehairing, and its process parameters are: the surface linear speed of the first upper rubber feed roller and the first lower rubber feed roller are both 10 m / min, and the spunlace head The distance between the parts and the top of the dehydration box is 30 mm, the water pressure of the water thorn head parts is 20 MPa, the diameter of the water jets injected from top to bott...

Embodiment 2

[0073] The polytetrafluoroethylene membrane split fiber tow that is 2200 and the number of hairs per unit length is 46 as the primary tow is the linear density obtained by the conventional membrane split method, and then its 40 bundles are tiled into a layer with a width of 200 mm. The tow layer with a thickness of 1.5 mm is regularly arranged after being combed by the comb needles 1002 of the first comb part 1, and then fed into the first horizontal type with three hydroentanglement head parts through the first pair of rubber feeding roller parts. The spunlace unit performs the first horizontal spunlace impact dehairing, and its process parameters are: the surface linear speed of the first upper rubber feed roller and the first lower rubber feed roller are both 6.5 m / min, the spunlace head The distance between the parts and the top of the dehydration box is 20 mm, the water pressure of the water thorn head part is 17 MPa, the diameter of the water jets injected from top to bot...

Embodiment 3

[0075]The polytetrafluoroethylene film-split fiber tow with a linear density of 2400 denier and a number of hairiness per unit length of 45 produced by the conventional film-split method is used as the primary tow, and then 30 bundles are flattened into a layer with a width of 150 mm. 1. The tow layer with a thickness of 1.5 mm is regularly arranged after being combed by the comb needles 1002 of the first comb part 1, and fed into the first horizontal layer with three spunlace head parts through the first pair of rubber feeding roller parts. Type spunlace unit performs the first horizontal spunlace impact dehairing, and its process parameters are: the surface linear speed of the first upper rubber feed roller and the first lower rubber feed roller are both 3 m / min, the spunlace head The distance between the part and the top of the dehydration box is 10 mm, the water pressure of the water thorn head part is 15 MPa, the diameter of the water jet injected from top to bottom is 0.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com