A device and method for improving the performance of compact spinning yarn

A spinning yarn compacting technology, which is applied in the field of devices for improving the performance of compact spinning yarns, can solve the problems of large notch area, large negative pressure, unfavorable energy consumption reduction, etc., and achieves simple structure, low energy consumption, and convenient The effect of transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

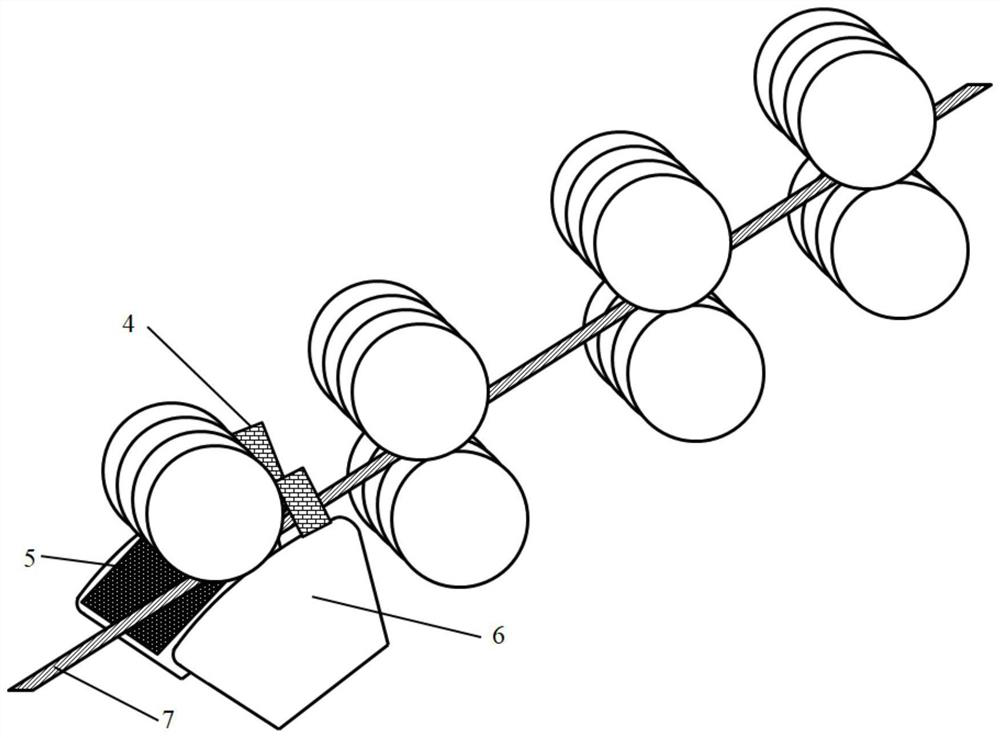

[0048] combine image 3 , a method for improving compact spinning performance, comprising the steps of:

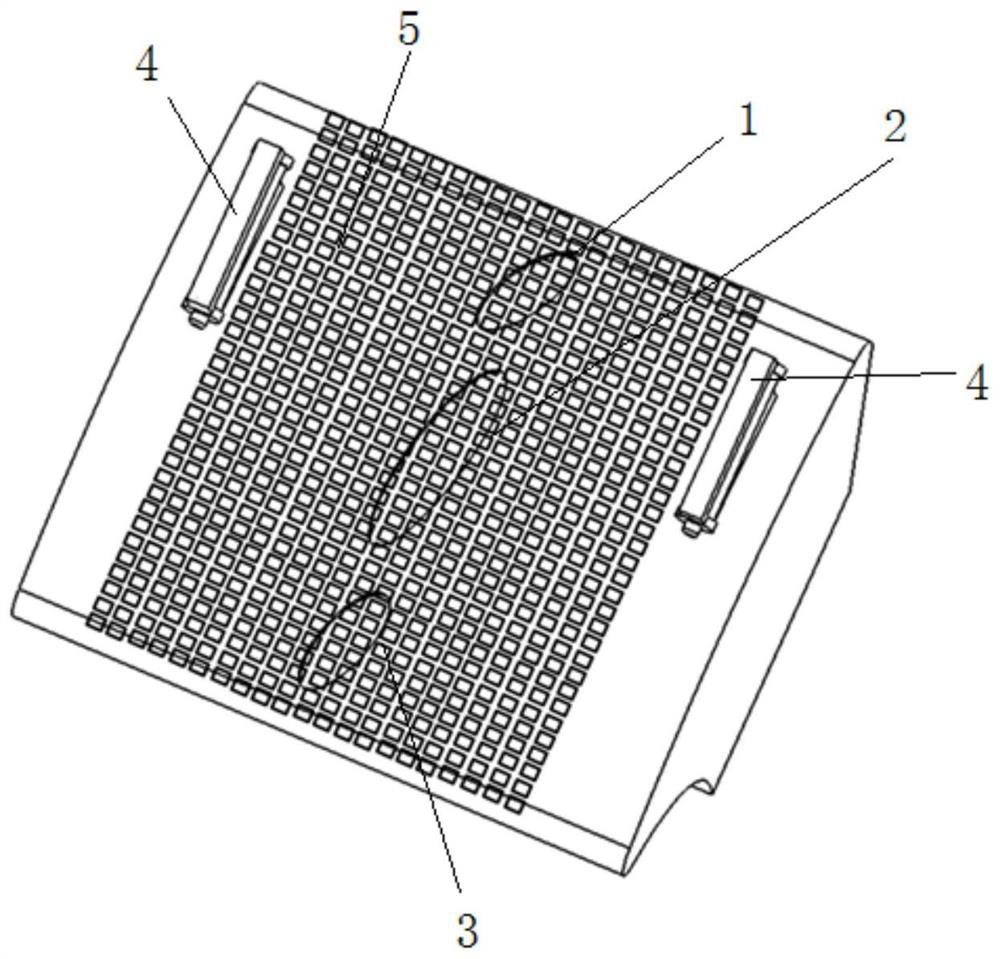

[0049] (1) The fineness of the yarn spun in this example is 14 lbs, and the yarn kind is 25 / 75 viscose / combed cotton blended yarn. Select the cover sheet whose first slit angle is 20°, the second slit angle is 15°, and the third slit angle is 13°, and fasten it on the compact spinning special-shaped tube 6 with four rollers and mesh ring 5 .

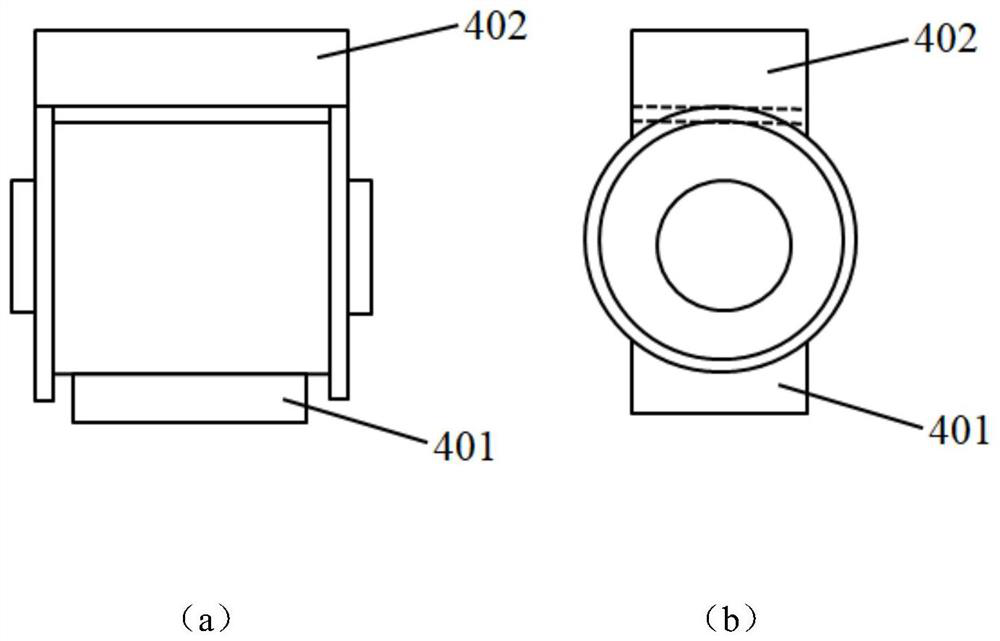

[0050] (2) According to the yarn fineness and variety, select the airflow guide piece 4 with a height of 5 mm, and insert it into the notch position on the cover piece, and set the angle of the angle-adjustable part 402 of the airflow guide piece 4 to -10 °, and then tighten the nuts to fix the airflow guide 4.

[0051] (3) Use a roving with a weight of 6.8g / 10m, and set the spindle speed to 12000r / min and the yarn twist to 550 twists / m according to the yarn fineness and variety.

[0052] (4) The yarn of this variety is relatively...

Embodiment 2

[0055] A method for improving the performance of compact spinning, comprising the steps of:

[0056] (1) The fineness of the yarn spun in this example is 21 pounds, and the yarn kind is viscose yarn. Select the cover sheet with the first incision angle of 16°, the second incision angle of 14°, and the third incision angle of 11°, and buckle it on the four-roller mesh ring-type compact spinning special-shaped tube.

[0057] (2) According to the yarn fineness and variety, select an airflow guide piece with a height of 7mm, and insert it into the notch on the cover piece, set the angle of the adjustable part of the airflow guide piece to 0°, and then tighten it Nuts to fix the air guide vane.

[0058] (3) Use a roving with a quantitative value of 5.1g / 10m, and set the spindle speed to 12000r / min and the yarn twist to 670 twists / m according to the yarn fineness and variety.

[0059] (4) According to the comprehensive consideration of yarn variety and roving quantity, adjust the ...

Embodiment 3

[0062] A method for improving the performance of compact spinning, comprising the steps of:

[0063] (1) The fineness of the yarn spun in this example is 30 pounds, and the yarn kind is 60 / 20 / 20 polyester / viscose / cotton blended yarn. Select the cover sheet with the first incision angle of 13°, the second incision angle of 12° and the third incision angle of 9°, and buckle it on the four-roller mesh ring type compact spinning special-shaped tube.

[0064] (2) According to the yarn fineness and variety, select an airflow guide with a height of 8mm, and insert it into the notch on the cover, set the angle of the adjustable part of the airflow guide to 15°, and then tighten it Nuts to fix the air guide vane.

[0065] (3) Use a roving with a weight of 6.2g / 10m, and set the spindle speed to 13000r / min and the yarn twist to 805 twists / m according to the yarn fineness and variety.

[0066] (4) According to the comprehensive consideration of yarn variety and roving quantity, adjust t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com