A Construction Method of Large Section Concrete Y-shaped Column

A construction method and concrete technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of high installation and positioning accuracy requirements for Y-shaped space modeling, difficult processing of bending and torsion components, complicated installation, assembly and construction, and simplify technical preparations The effect of reducing the workload, simplifying the difficulty of construction, and saving the overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

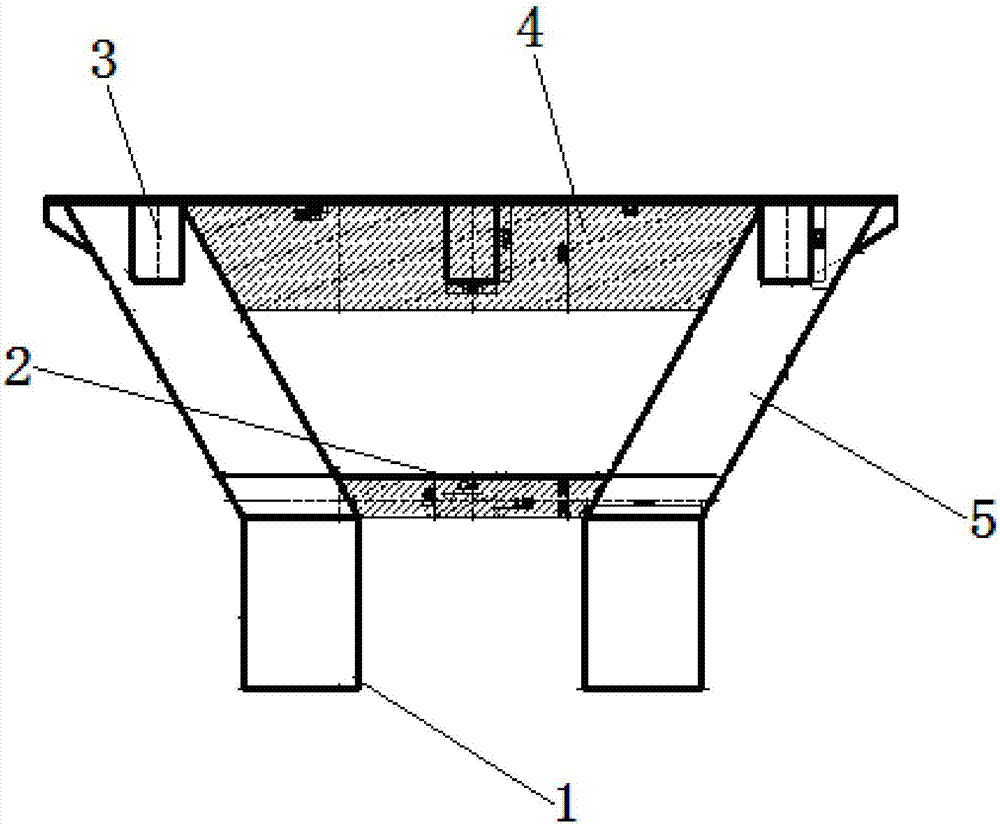

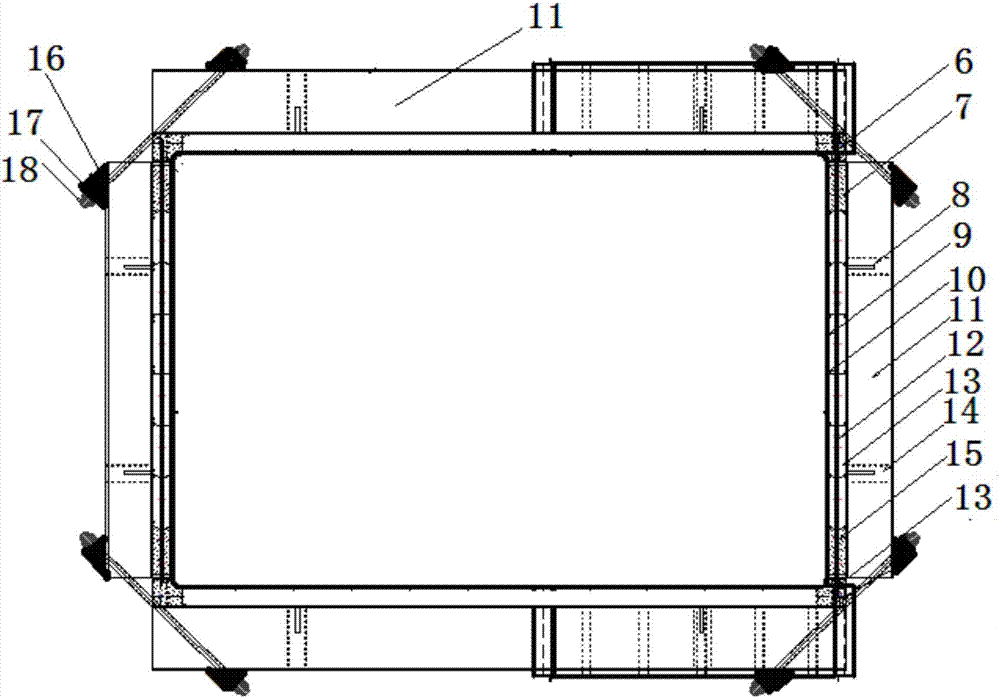

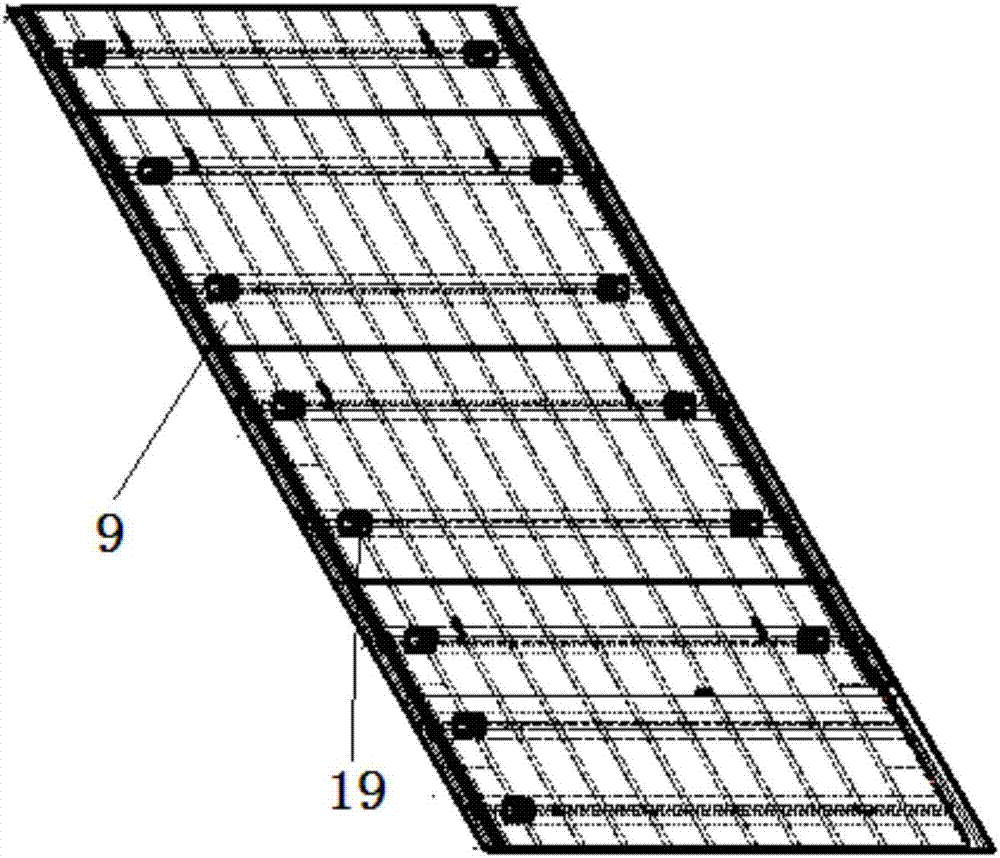

[0058] The construction process of a large-section concrete Y-shaped column construction method provided by the present invention is as follows: plane positioning and space line measurement → adjust the position of the steel bars below the joints of the inclined columns, tie the stirrups of the inclined columns below the joints → install the main reinforcement of the inclined columns Pull up in the opposite direction to the bottom formwork of the column → Bind the steel bars and stirrups above the mechanical connection joints → Check the hidden reinforcement of the inclined column → Formwork for the four-sided inclined column → Strengthen the formwork and support system for the inclined column, and correct the position of the inclined column again → Pour concrete for the inclined column → After the concrete strength reaches 1.2MPa, the inclined column fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com