Weight type steel pipe pile foundation of transmission line self-supporting rod

A technology for power transmission lines and steel pipe piles, applied in infrastructure engineering, construction, etc., can solve the problems of long construction period, short construction period, and large geological impact, and achieve the improvement of component bearing capacity, speed up construction progress, and increase lateral The effect of earth pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

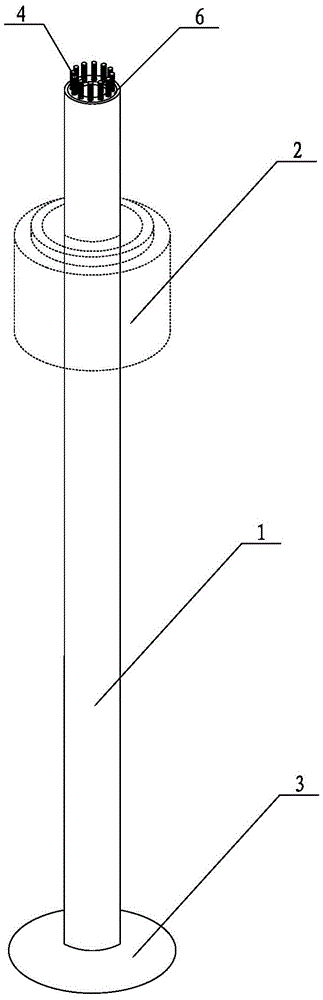

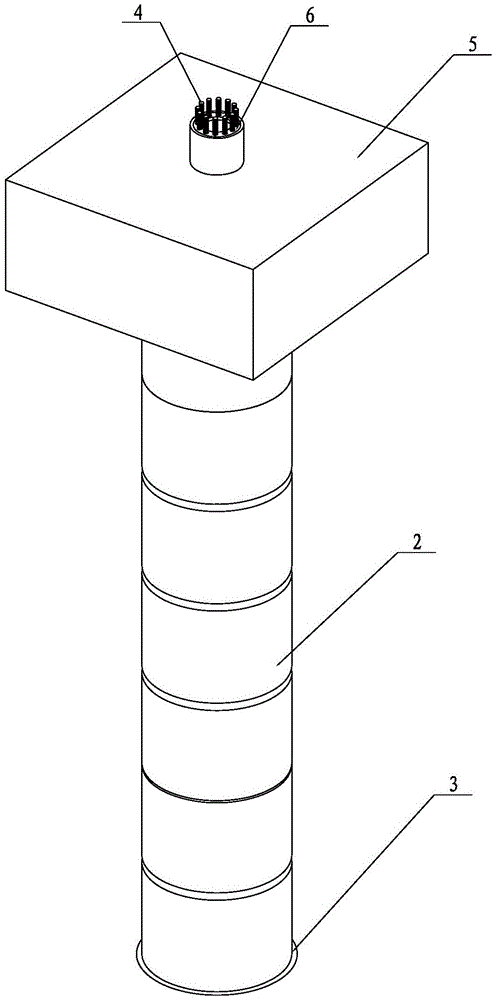

[0016] Such as Figure 1-2 As shown, a weight-type steel pipe pile foundation for a self-supporting pole of a power transmission line includes a steel pipe pile body 1, and several prefabricated concrete blocks 2 sleeved on the steel pipe pile body 1, and the steel pipe pile body 1 There is a steel plate 3 at the bottom, and the steel plate 3 is used to carry each precast concrete block 2. The precast concrete blocks 2 on the steel pipe pile body 1 are connected in series to form a weight group, and the top of the weight group is covered with a precast concrete cap 5 , the top of the steel pipe pile body 1 is provided with a flange 6, the flange 6 is located inside the steel pipe pile body 1, and the flange 6 is provided with a bolt 4 for installing a steel pipe. Each prefabricated concrete block 2 of the weight group is cylindrical and has the same size and size. There is a through hole in the middle of the prefabricated concrete block 2 for the steel pipe pile body 1 to pass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com