Rebar-embedded steel-pipe-coated buckling restrained brace

A technology of outsourcing steel pipes and buckling constraints, which is applied to building components, earthquake resistance, etc., can solve the problems of affecting the range of support, large size of support components, and large moment of inertia of the core material section.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

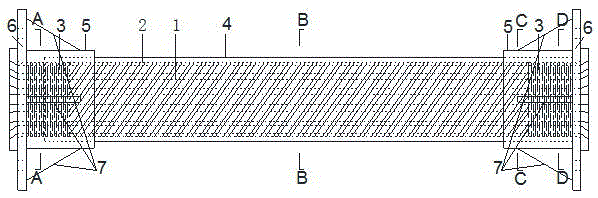

[0022] Attached below Figure 1-Figure 9 The present invention is further described.

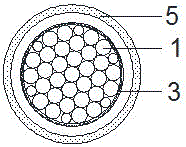

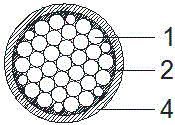

[0023] A schematic diagram of the structure and components of a buckling-restrained brace with embedded steel bars and outsourced steel pipes is shown in Figure 1-Figure 9 shown. Determine the length of the smooth round steel bar 1 according to the support arrangement and the height of the storey, and determine the diameter and number of a single smooth round steel bar 1 according to the limit value of the interstory displacement angle, and then determine the length and cross-sectional size of the restrained steel pipe 4 to restrain the steel pipe 4 and one end of the end reinforcement pipe 5 is turned outside. Multiple light round steel bars 1 are straightened and aligned at both ends. According to needs, they are combined into a circular or rectangular cross section. One end of the mechanical pier head needs to be polished. The section size of the pier head after processing should be la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com