Stress application centrifugal pump with pressurization hole

A technology of booster hole and centrifugal pump, which is applied to the parts, pumps and pump elements of the pumping device for elastic fluids, can solve the problems of cavitation damage of the afterburner centrifugal pump, prolong the service life and ensure the operation. Safety and avoidance of cavitation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

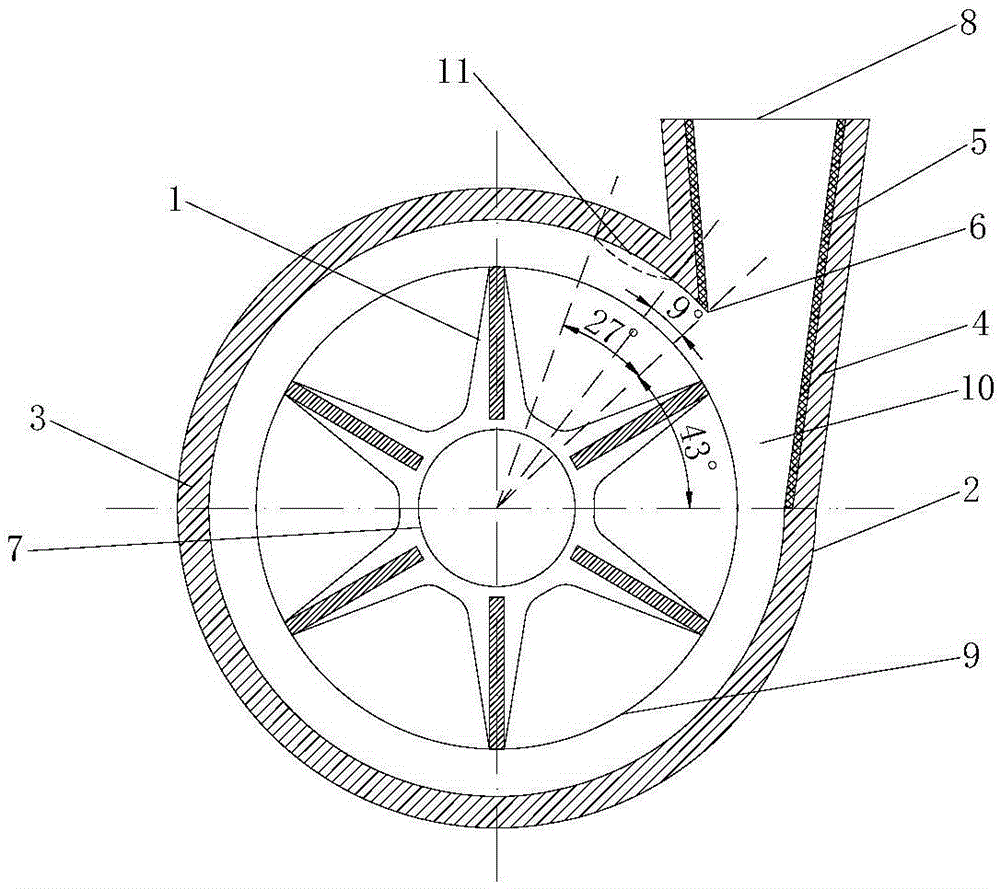

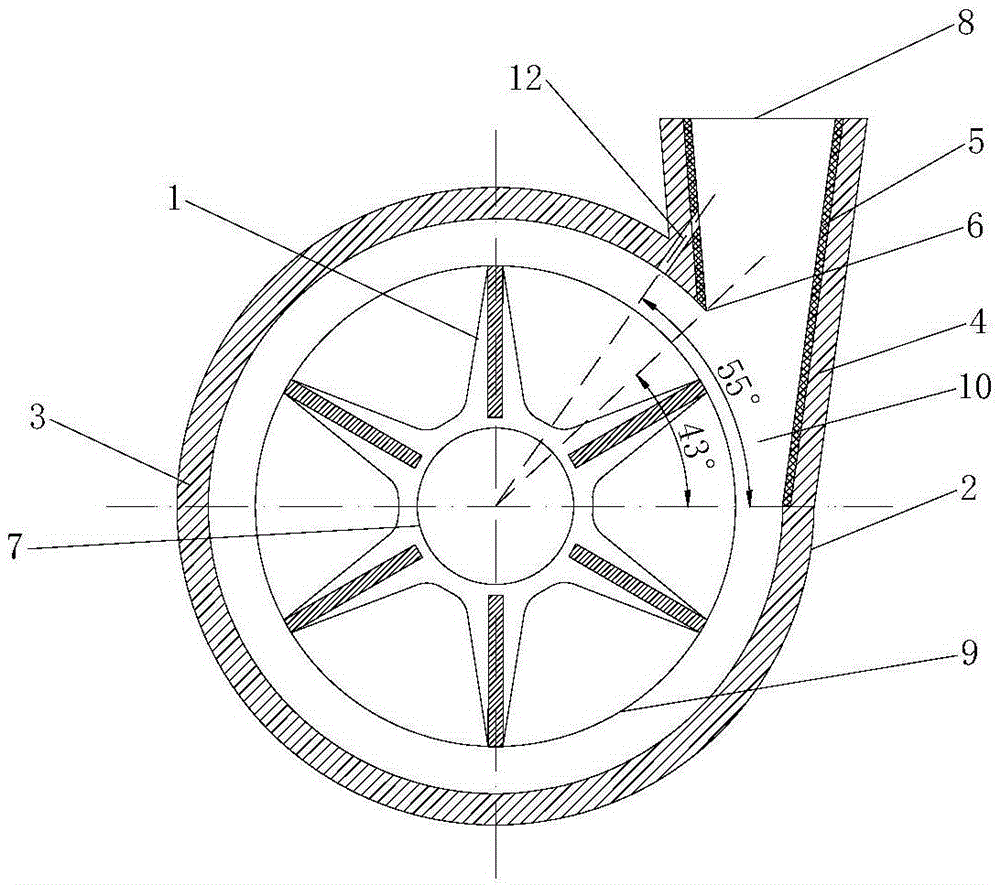

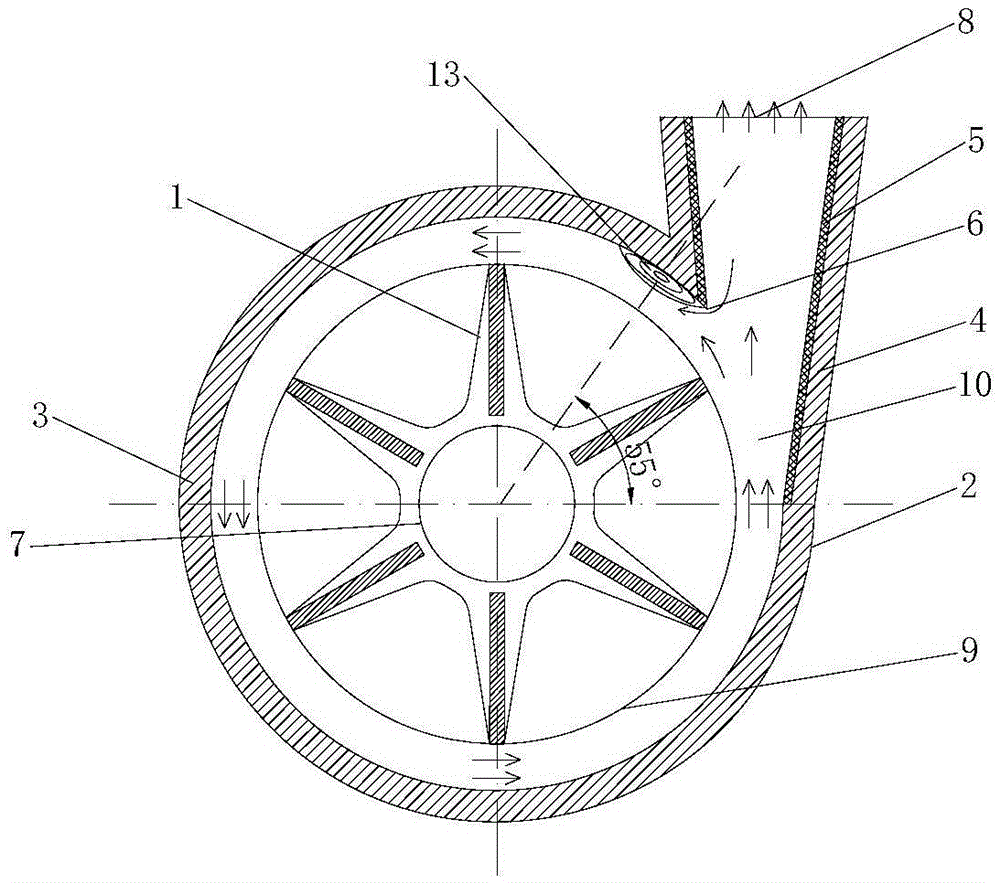

[0014] The present invention proposes a booster centrifugal pump structure with booster holes, such as figure 2 shown. The booster centrifugal pump is an improvement to the existing booster centrifugal pump, and is composed of an impeller 1 and a casing 2 , and the casing 2 includes a volute 3 and a diffuser tube 4 . The impeller 1 adopts a radial straight impeller, and the volute 3 adopts a concentric volute with a semicircular section shape, and the impeller 1 is installed in the volute 3 . The diffuser 4 is a conical diffuser, and the diffuser 4 communicates with the volute 3 . A tapered sleeve 5 is provided on the inner wall of the diffuser 4 . A partition tongue 6 is formed at the junction of the volute 3 and the tapered casing 5, and the installation angle of the partition tongue 6 is 43°. A pump inlet 7 concentric with the impeller is provided at the center of the volute 3 , the outlet of the diffuser pipe 4 is the pump outlet 8 , and the outline formed by the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com