Heat Exchanger

A heat exchanger and heat exchange unit technology, applied in evaporators/condensers, lighting and heating equipment, refrigeration components, etc., can solve the problems of large temperature difference and uneven air temperature, and achieve uniform and distributed air temperature. Uniform and high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

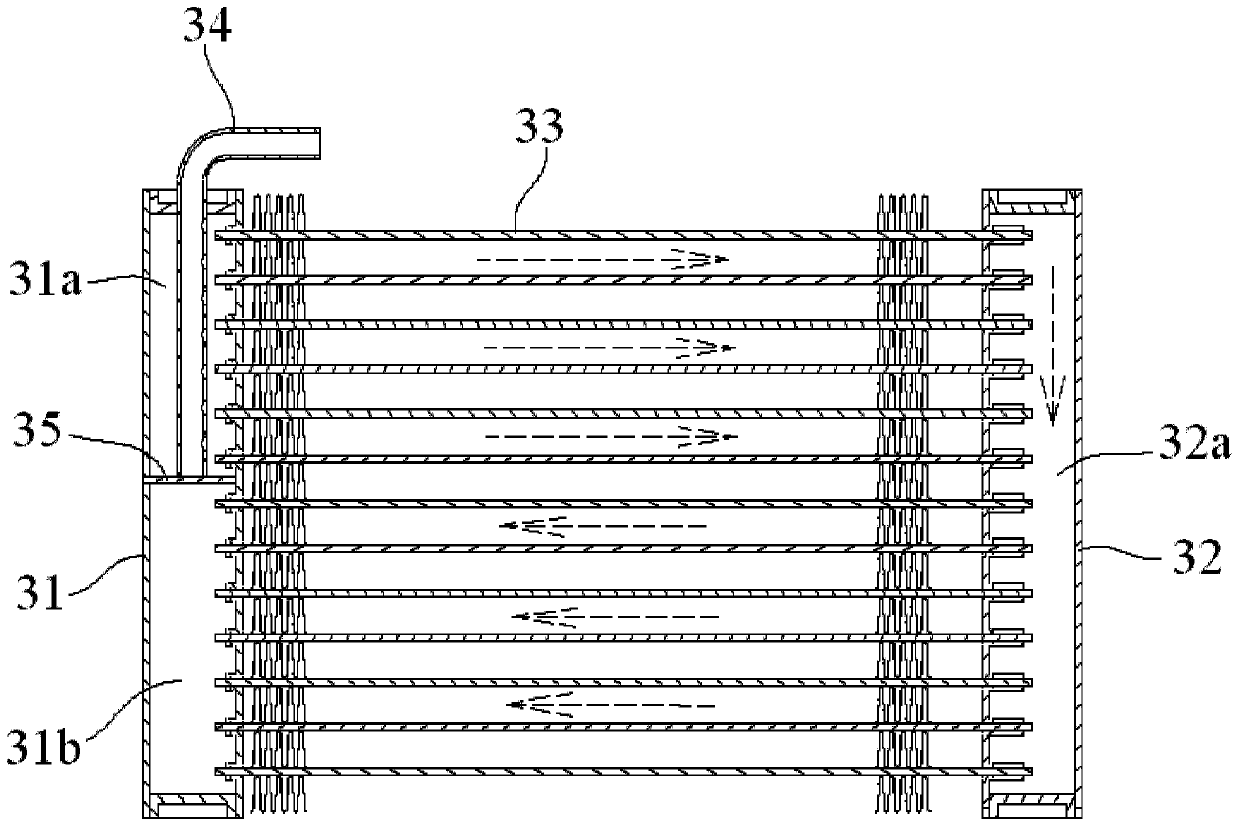

[0055] Figure 4 A schematic perspective view showing the heat exchanger 100 according to the first embodiment of the present invention; Figure 5 show Figure 4 A partially enlarged schematic diagram of the heat exchanger 100 shown; Figure 6 show Figure 4 and Figure 5 An enlarged schematic view of the connecting component 140 in .

[0056] Such as Figure 4 As shown, in the first embodiment of the present invention, a heat exchanger 100 is disclosed. The heat exchanger 100 mainly includes an inlet header 111, a first header 121, and a second header 122. , an outlet pipe 112 , a plurality of first flat pipes 131 , a plurality of second flat pipes 132 and a communication part 140 .

[0057] Please continue to see Figure 4 , in the illustrated embodiment, the inlet header 111 and the first header 121 are in fluid communication with each other through a plurality of first flat tubes 131, and the outlet tube 112 and the second header 122 are in fluid communication with ...

no. 2 example

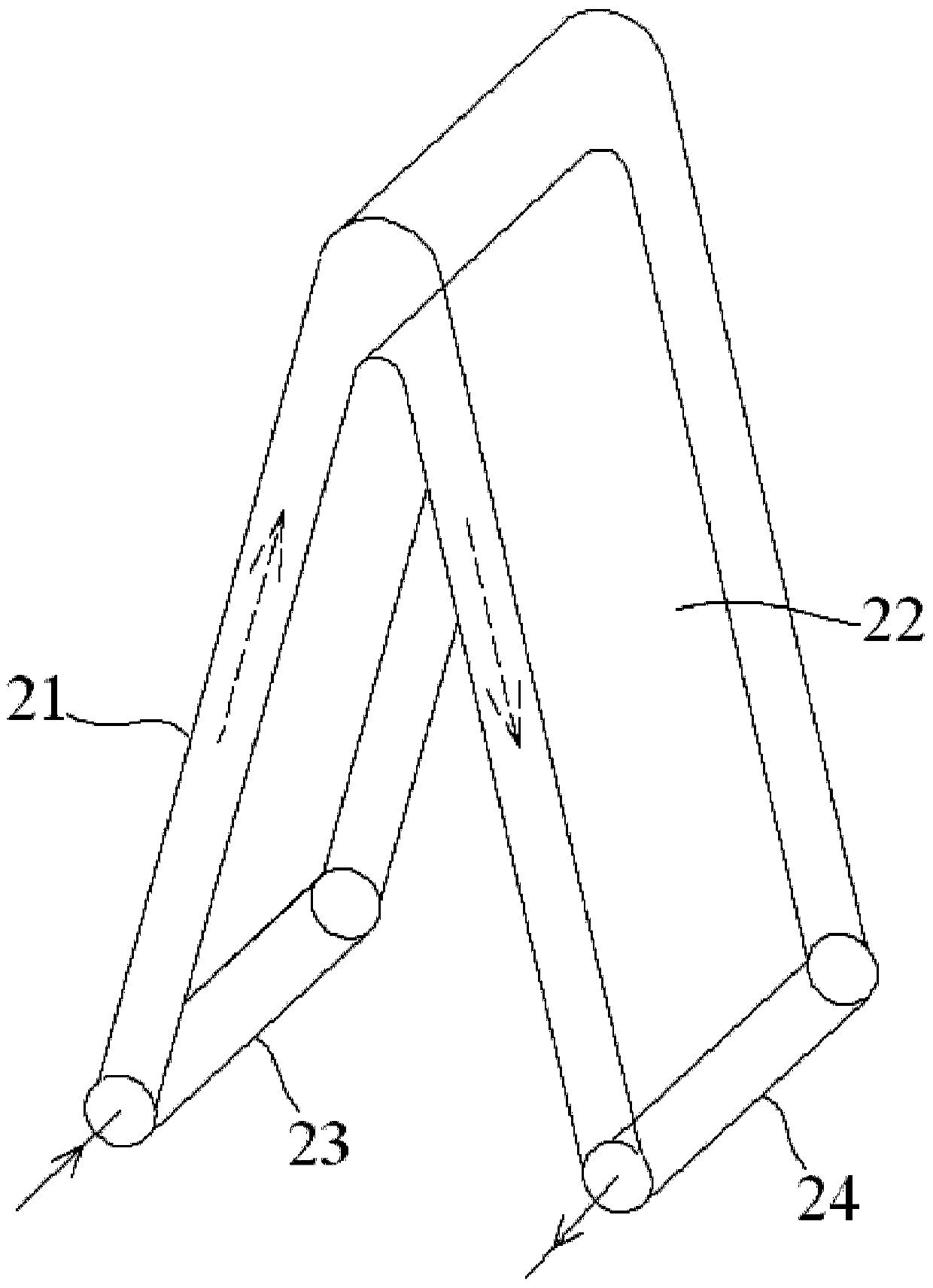

[0071] Figure 7 A schematic perspective view showing a heat exchanger according to a second embodiment of the present invention; Figure 8 show Figure 7 An enlarged schematic view of the connecting component 240 in .

[0072] In the second embodiment of the present invention, as Figure 7 As shown, a heat exchanger is disclosed, which mainly includes two heat exchange units 210, 220 (the first heat exchange unit 210 and the second heat exchange unit 220). Each heat exchange unit 210, 220 includes a first tube 210a, 220a, a second tube 210b, 220b and an intermediate communication tube 211, 221 connecting the first tube 210a, 220a and the second tube 210b, 220b. In the illustrated embodiment, the intermediate communication pipes 211 and 221 are twisted flat pipes.

[0073] In one embodiment of the present invention, as Figure 7 and Figure 8 As shown, the communication part 240 includes a first branch pipe 241 , a second branch pipe 242 and a third branch pipe 243 which...

no. 3 example

[0086] Figure 11 shows a schematic diagram of a heat exchanger according to a third embodiment of the present invention; and Figure 12 show Figure 11 The enlarged schematic diagram of the communication part 340 in and the header 310 connected with the communication part 340 .

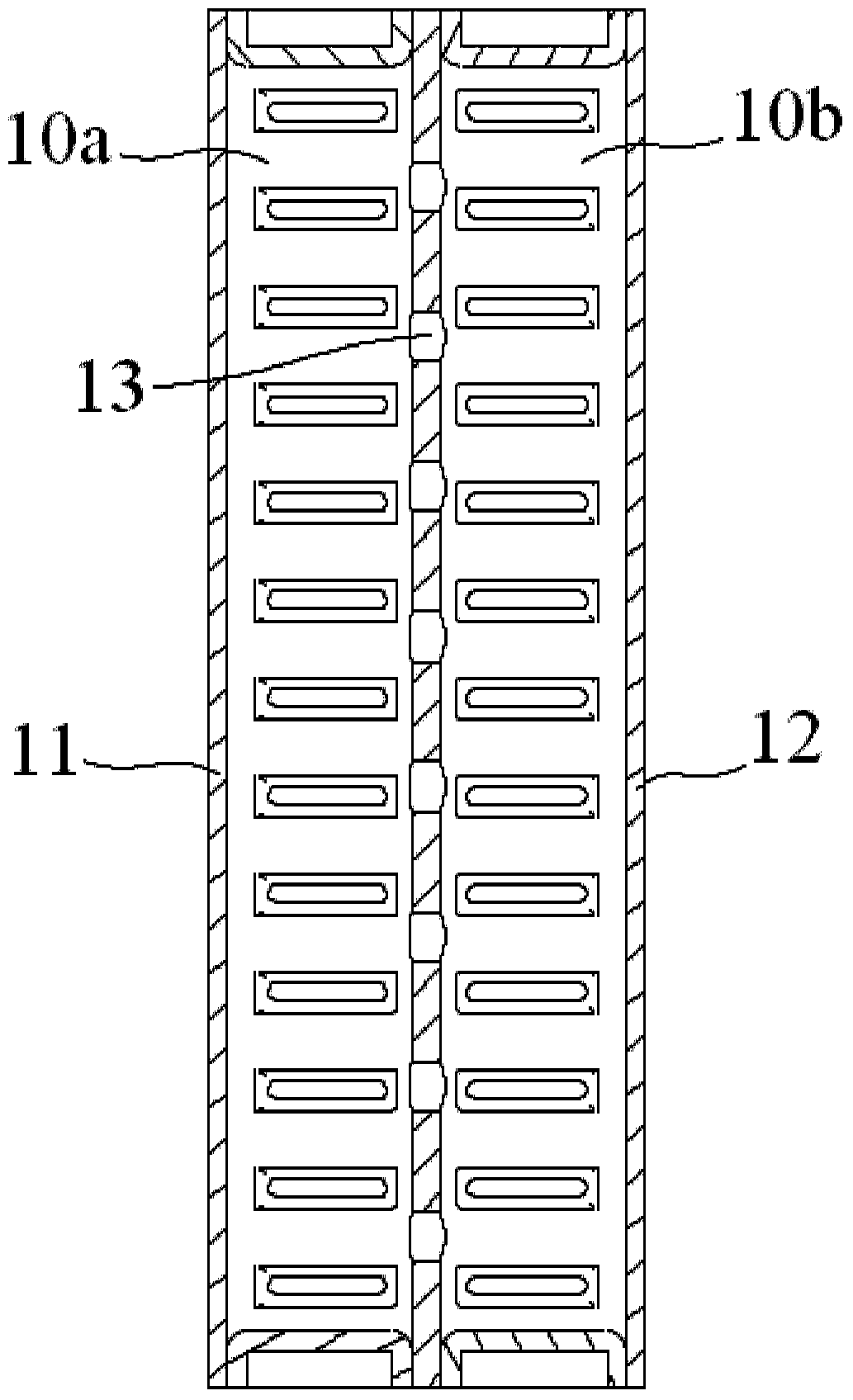

[0087] Such as Figure 11 and Figure 12 As shown, in the third embodiment, a heat exchanger is disclosed, which mainly includes a first header 310 , a second header 320 , a plurality of flat tubes 330 and a communication part 340 .

[0088] In one embodiment of the present invention, as Figure 11 and Figure 12 As shown, the inner space of the first header 310 is divided into a first chamber a, a second chamber b and a third chamber c by two partition plates 311, 312, wherein the third chamber c is located at the Between the first chamber a and the second chamber b.

[0089] In one embodiment of the present invention, as Figure 11 and Figure 12 As shown, the first chamber a, the second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com