Optical Sensing 3D High Precision Contact Scanning Measuring Probe

A measuring probe and sensing technology, applied in the field of micro-nano testing, can solve the problems of difficult assembly and adjustment, low detection sensitivity and accuracy of strain gauges, complicated decoupling, etc., to save probe space and cost, realize three-dimensional scanning measurement, The effect of high sensitivity and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

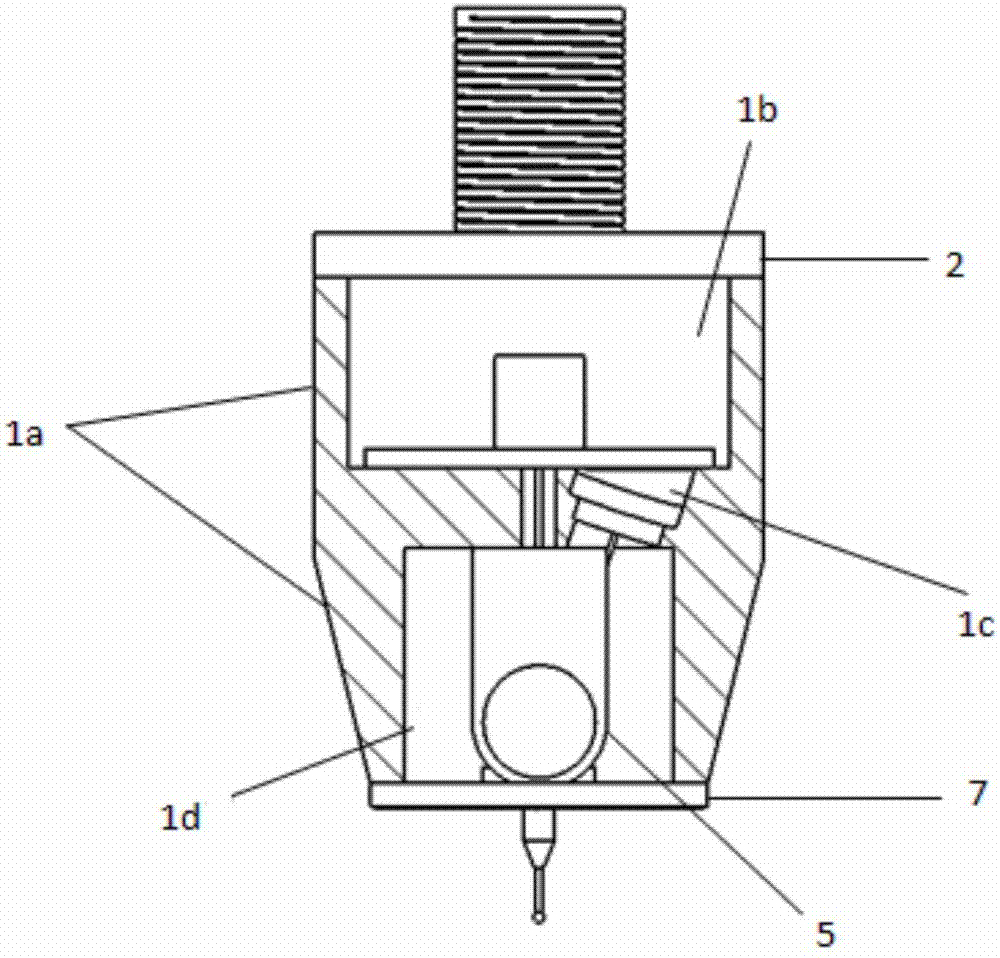

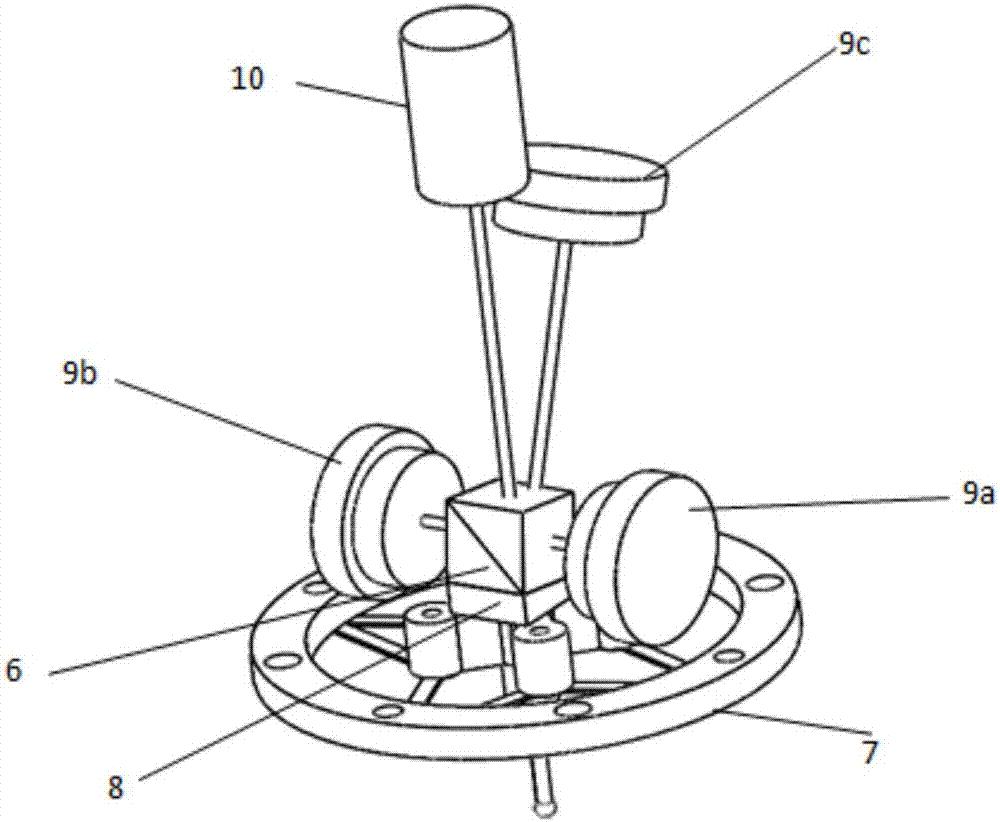

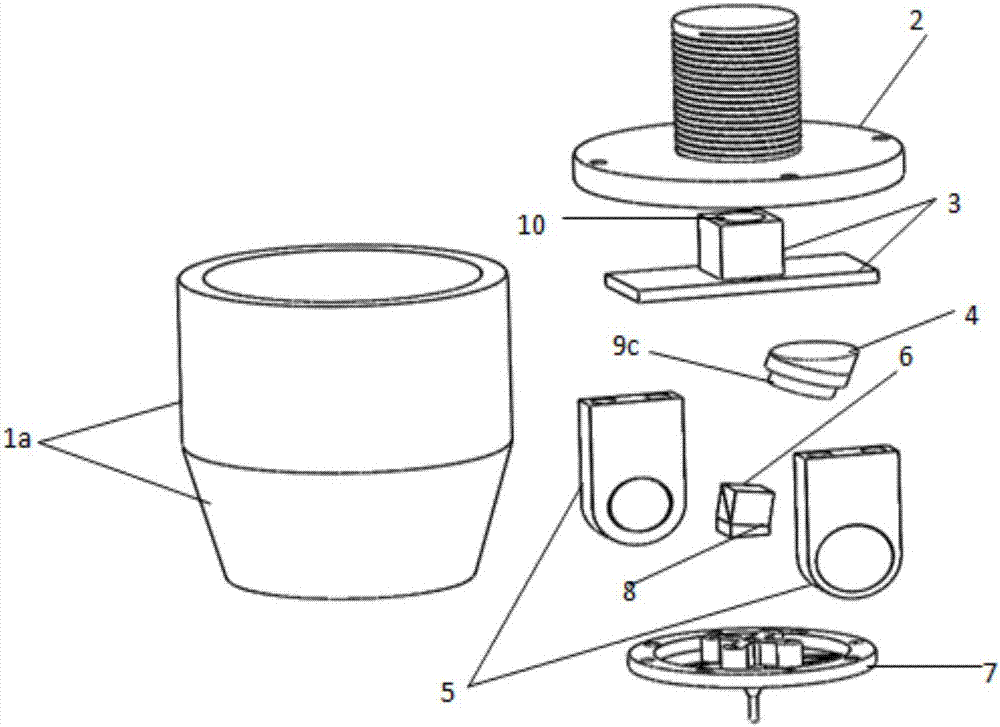

[0024] The structure of the optical sensing type three-dimensional high-precision contact scanning measurement probe in this embodiment is set as follows:

[0025] see figure 2 , Figure 4 and Figure 5 , the probe unit 7 is provided with a cross suspension piece 7b in the center of the ring seat 7a, each cantilever end of the cross suspension piece 7b is fixedly connected to the top of the "V" type cantilever reed 7c at the corresponding position, and the "V" type cantilever spring The two bottom ends of the sheet 7c are fixedly connected to the ring seat 7a to form the suspension structure of the cross suspension sheet 7b in the ring seat 7a; the upper surface of the cross suspension sheet 7b is fixedly arranged in the center of the cross suspension sheet 7b The wedge block 8 is bonded with NPBS6 on the top surface of the wedge block 8, coated with a reflective layer on the bottom surface of the wedge block 8, and fixedly connected with a measuring ball on the lower surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com