Test box and system capable of simulating mechanical property of test piece under freeze-thaw temperature load

A test box and test piece technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of engineering practical application errors and inaccurate test results, and achieve the benefits of accuracy, efficiency and convenience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

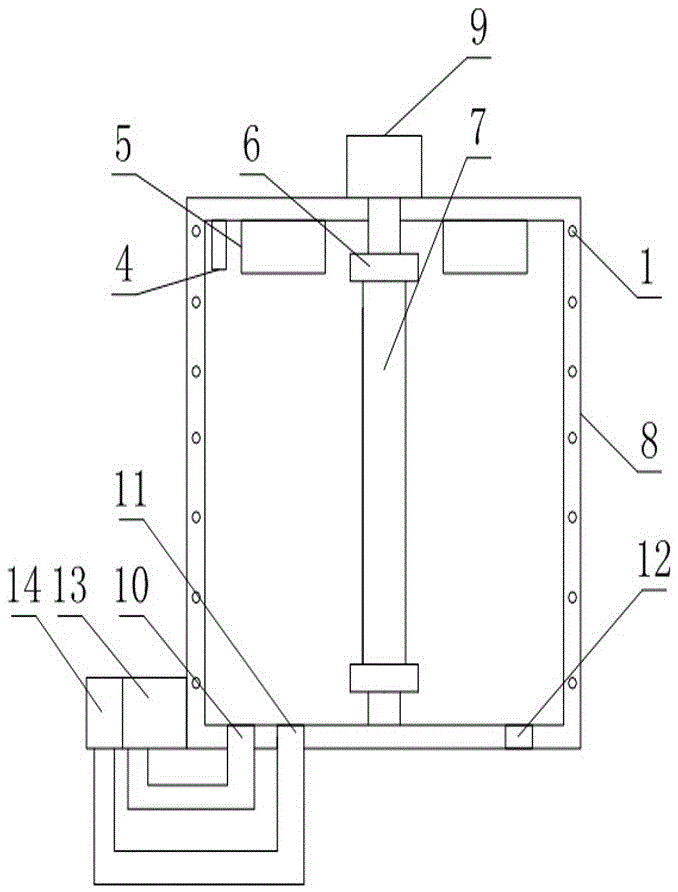

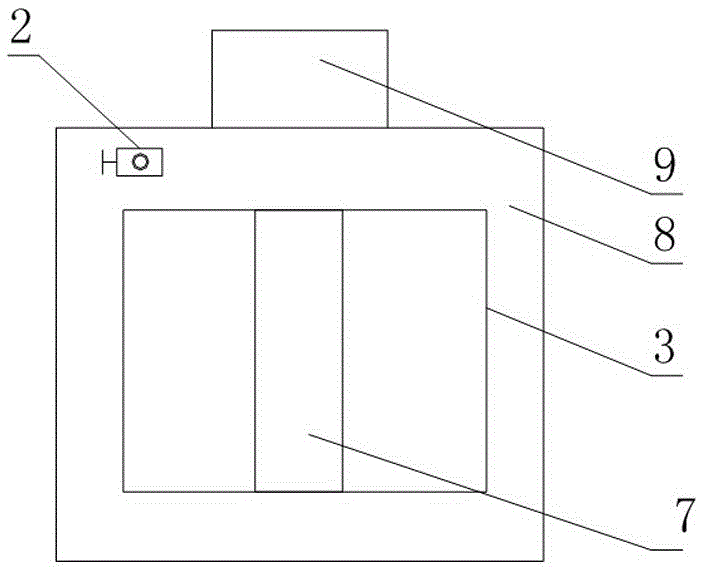

[0038] Such as Figure 1 to Figure 2 As shown, a test chamber capable of simulating the mechanical properties of specimens under freeze-thaw temperature loads includes a case body 8, a refrigeration device 1 arranged in the case body 8, and a cooling device 1 arranged on the case wall of the case body 8 The atomizing liquid inlet 10 or the atomizing device 13 arranged in the box body 8 .

[0039] Specifically, various components in a freeze-thaw environment are subject to various complex loads: mechanical loads and alternating loads, while the humidity level in the air and whether acid rain has corrosion properties have a great impact on the durability of the components. In the prior art, for the mechanical performance experiment of specimen 7 under freeze-thaw temperature load, stress loading was carried out respectively when specimen 7 was below 0°C and above 0°C, and the final freeze-thaw temperature load was completed through repeated temperature rise and fall. Determinat...

Embodiment 2

[0046] Such as Figure 1 to Figure 2 As shown, this embodiment is further limited on the basis of Embodiment 1: in order to adjust the humidity and temperature in the box body 8 in a timely, efficient and accurate manner, the wall of the box body 8 is also provided with a dry gas Inlet 11 and air convection hole 12. The above dry gas inlet 11 is used to pass dry gas into the box body 8, and the above air convection holes 12 are used for the box body 8 to exhaust from inside to outside. In this solution, the dry gas inlet 11 is connected to a blast drying device 14, and the blast drying device 14 includes an air compressor and a drying tank, the outlet of the air compressor is connected to the inlet of the drying tank, and the drying tank is provided with As the filler of alumina particles, the drying tank is also provided with an alumina heating regeneration device, and the outlet of the drying tank is connected with the drying gas inlet 11 .

[0047] In order to facilitate ...

Embodiment 3

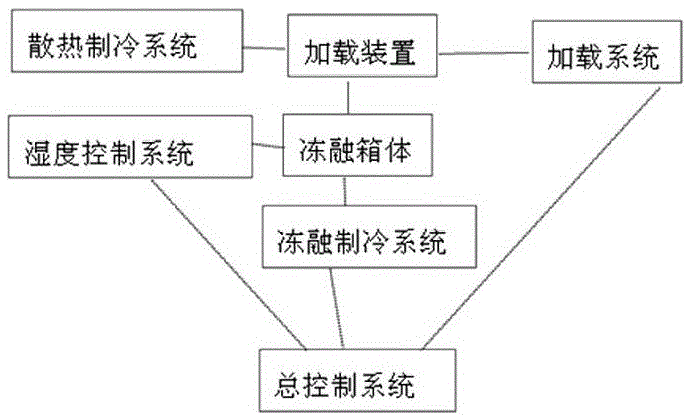

[0052] A system that can simulate the mechanical properties of specimens under freeze-thaw temperature loads, such as Figure 1 to Figure 3 As shown, the system includes a stress loading device 9 and any test chamber provided in any one of the above embodiments. The specimen fixing end of the stress loading device 9 is located inside the box body 8 .

[0053] In the above-mentioned system that can simulate the mechanical properties of the test piece under the freeze-thaw temperature load, the set stress loading device 9 is used to apply the stress that needs to be simulated to the test piece 7, and the above stress loading device 9 is used to apply the stress to the test piece 7. Load tensile stress, compressive stress, alternating stress, etc., such as using the end of the piston rod of a pneumatic cylinder or a hydraulic cylinder to act on the test piece 7, and using a piezoelectric transducer, a displacement amplifier connected in series, and an ultrasonic signal generator a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com