Device and method for testing adsorption heat effect of adsorbent

A testing device and testing method technology, applied in the direction of measurement device, material thermal development, instrument, etc., can solve the problems such as the patent report of the adsorbent thermal effect testing device that has not yet been seen, and achieve the effect of simple device setup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0044] This patent takes activated carbon as an adsorbent to adsorb toluene as an example to measure the thermal effect of activated carbon adsorption;

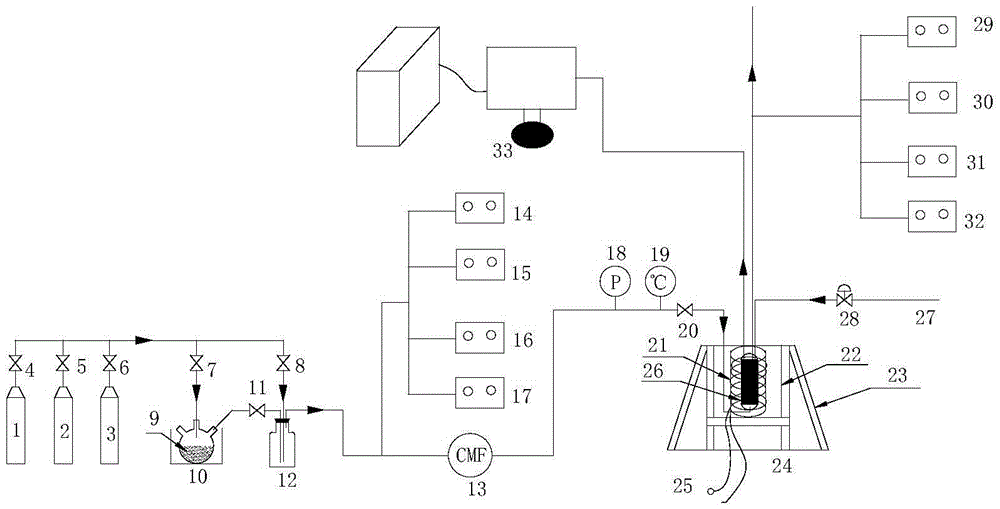

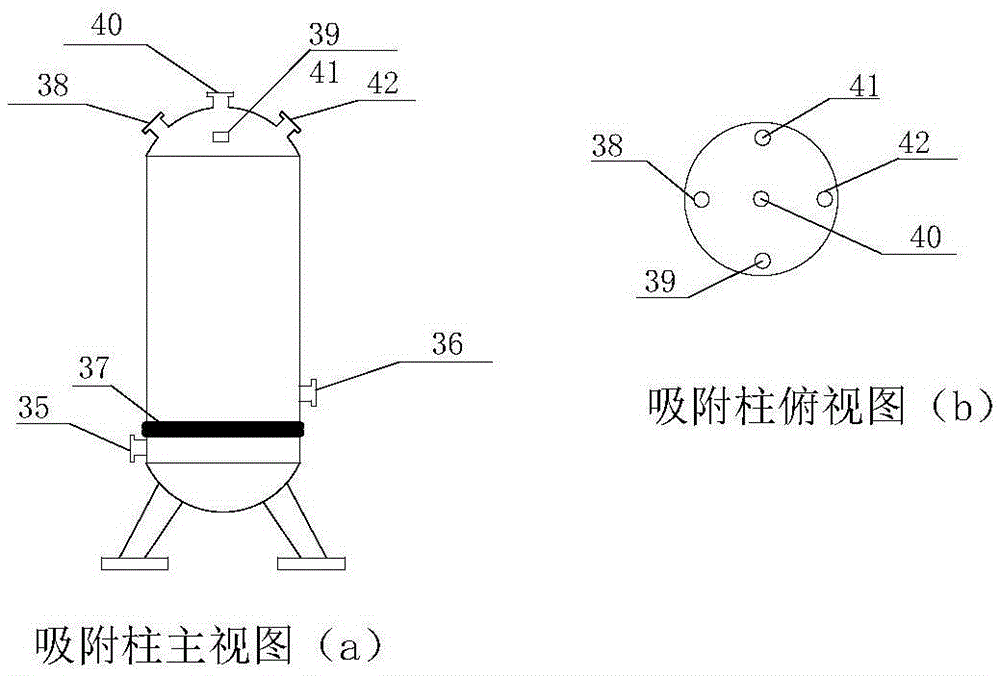

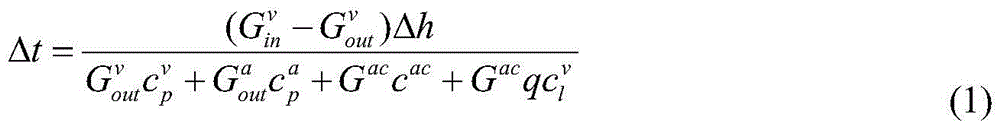

[0045] 1 cylinder N 2 bottle(1), air bottle(2), O 2 The bottle (3), the organic liquid bottle (9), and the gas buffer bottle (12) are connected in sequence through pipelines; the mass flow meter (13), pressure gauge (18), and thermometer (19) are connected to the gas buffer bottle (12) in sequence On the subsequent pipeline, the import CO concentration detector (14), the import CO 2 Concentration measuring instrument (15), import O 2 The concentration detector (16) and the imported VOCs concentration detector (17) are connected to the pipeline respectively; then the pipeline is connected from the bottom of the adsorption column (26), and the sensor (33) of the multi-channel temperature tester is put into the adsorption column (26); outlet CO concentration detector (29), outlet CO 2 Concentration measuring instrument (30),...

Embodiment example 2

[0055] This patent takes activated carbon as an adsorbent to adsorb toluene as an example, and measures the ignition temperature of activated carbon;

[0056] 1 cylinder N 2 bottle(1), air bottle(2), O 2 The bottle (3), the organic liquid bottle (9), and the gas buffer bottle (12) are connected in sequence through pipelines; the mass flow meter (13), pressure gauge (18), and thermometer (19) are connected to the gas buffer bottle (12) in sequence On the subsequent pipeline, the import CO concentration detector (14), the import CO 2 Concentration measuring instrument (15), import O 2 The concentration detector (16) and the imported VOCs concentration detector (17) are connected to the pipeline respectively; then the pipeline is connected from the bottom of the adsorption column (26), and the sensor (33) of the multi-channel temperature tester is put into the adsorption column (26); outlet CO concentration detector (29), outlet CO 2 Concentration measuring instrument (30), o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com