A real-time quality management system for steel pipe circulation process using rfid

A quality management and RFID tag technology, applied in the field of real-time quality management system, can solve problems such as difficulty in finding the cause of problems in real time, waste of management resources and production resources, unstable production process, etc., to improve management efficiency and production efficiency, The effect of reducing defective rate and high real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

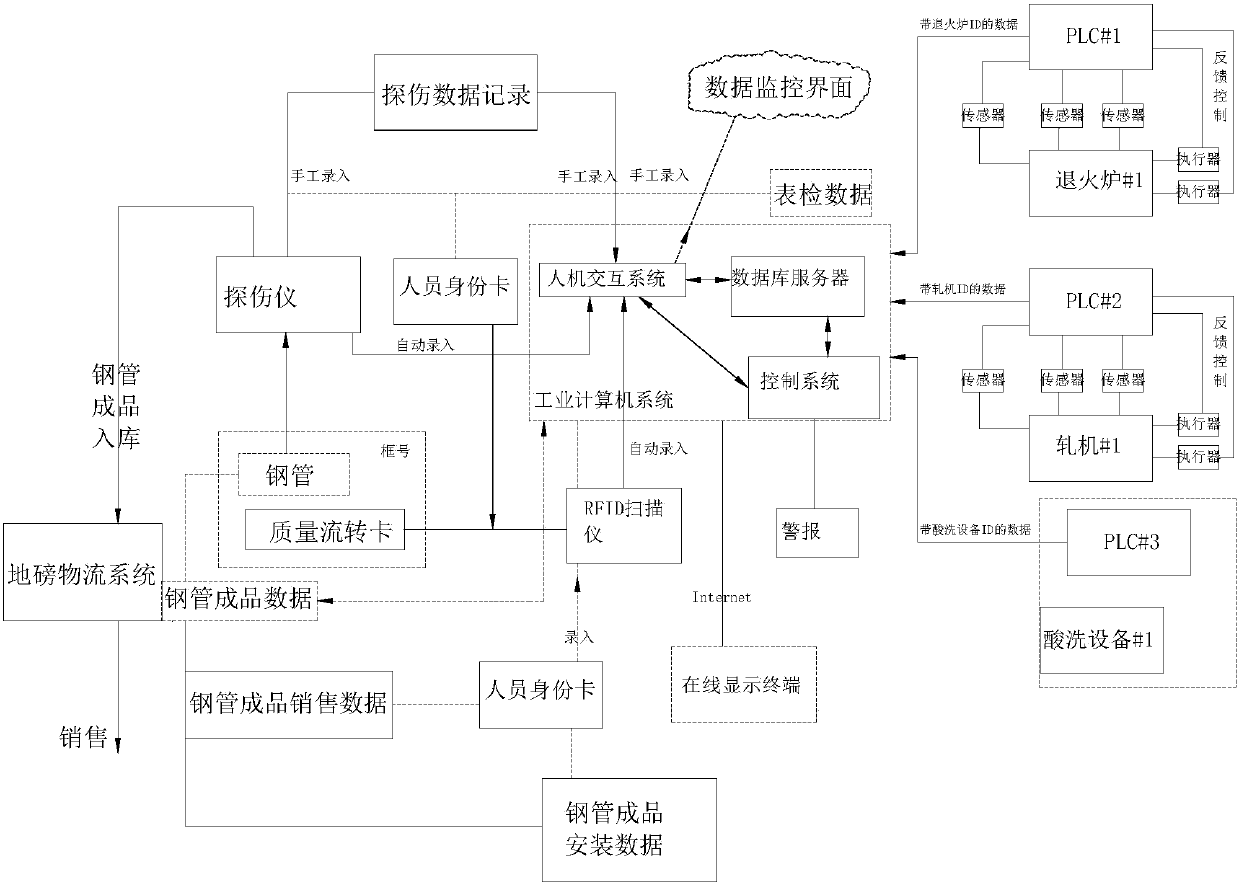

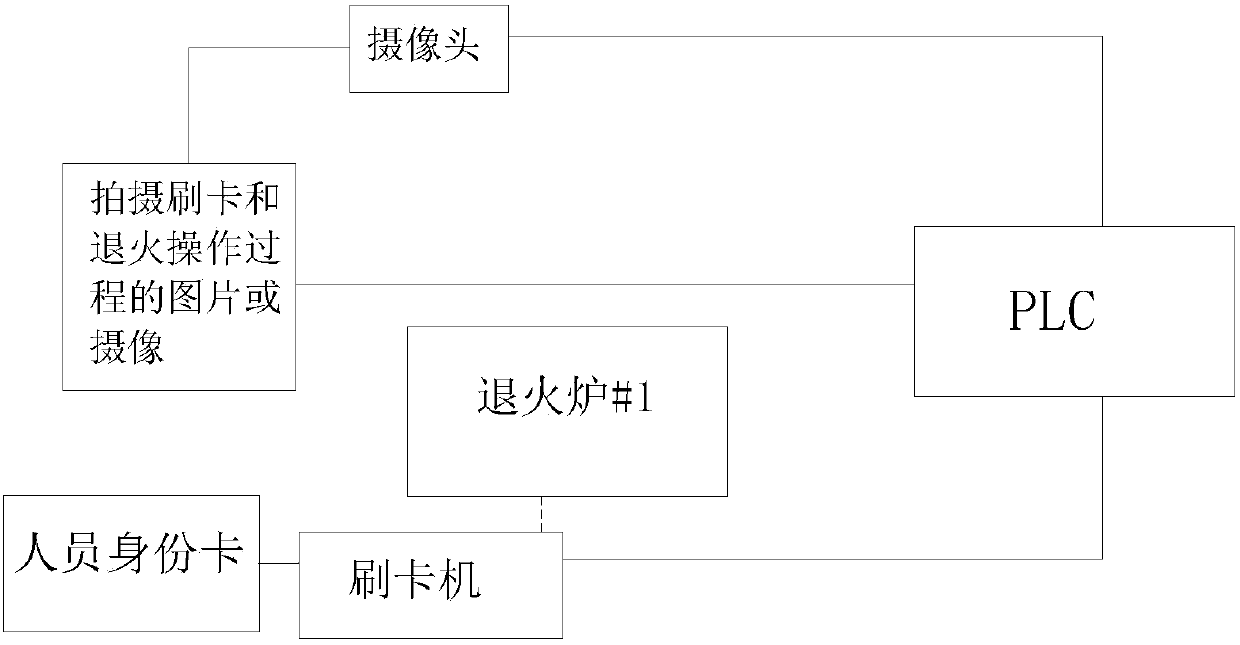

[0035] Such as figure 1 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment also includes a finished steel pipe quality management system, and the finished steel pipe quality management system includes finished steel pipes with RFID tags, a database server that pre-stores finished steel pipe data, remote RFID scanning instrument and remote input terminal; RFID personnel identification cards also include sales personnel identification cards and installation personnel identification cards. The sales data of the finished steel pipe is entered into the remote input terminal through the identity card of the salesperson behind the remote RFID scanner, and the remote input terminal is connected to the industrial computer system. figure 1 The remote RFID scanner is not shown in the figure, and the RFID scanner of Embodiment 1 is used instead. The installation data of the finished steel pipe is entered into the remote input terminal after the inst...

Embodiment 3

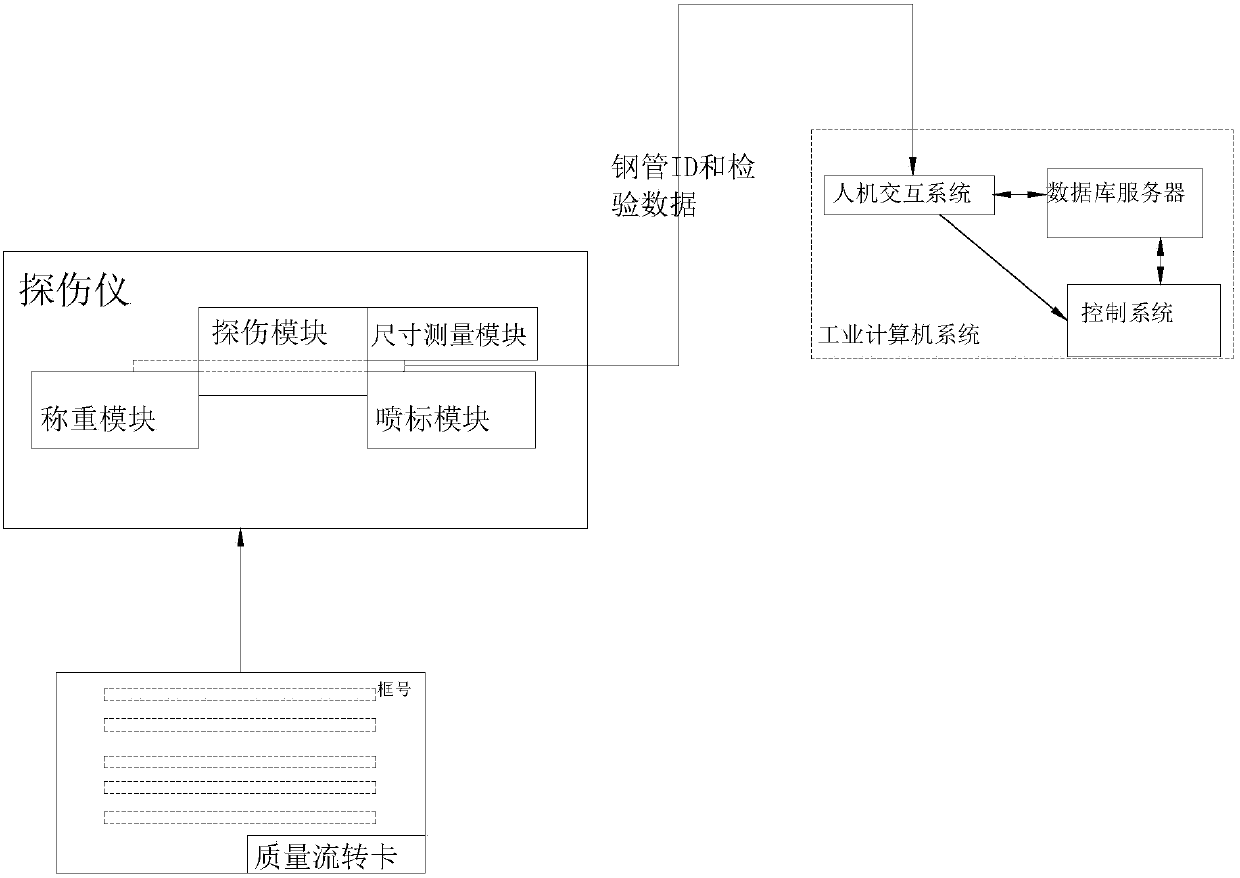

[0038] Such as figure 1 and figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the flaw detector of this embodiment is an integrated flaw detector, which includes a flaw detection module, a weighing module, a size measurement module and a labeling module, and the labeling module includes an ID spraying module. and the scale spraying module, and the scale spraying module is connected to the dimension measuring module for signals. The output end of the above-mentioned flaw detector is connected to the industrial computer system, and the ID and inspection data of each steel pipe are input into the database. When the steel pipes are fed into the flaw detector successively from the frame, the flaw detector uses the flaw detection module to detect flaws, the weighing module to weigh, and the size measurement module to measure the length and diameter of a single steel pipe, and finally uses the ID spraying module to mark the ID number on the surface ...

Embodiment 4

[0041] Such as figure 1 and Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment also includes a weighbridge logistics system, and the weighbridge logistics system includes an entry information entry system 1, an export information confirmation system 3, a loading system 2, an access control system, a weighbridge system, Information card with RFID tags 4, RFID personnel identification card, RFID scanner, data center, control center and online display terminal, access control system includes storage access control and storage access control, and the weighbridge system includes the double-weighing mechanism of the empty scale mechanism. The data center connects, collects and processes the feedback data of the RFID scanning machine, the empty scale mechanism and the double scale mechanism, and the data center connects with the control center and sends the control signal to the control center. The control center is connected to and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com