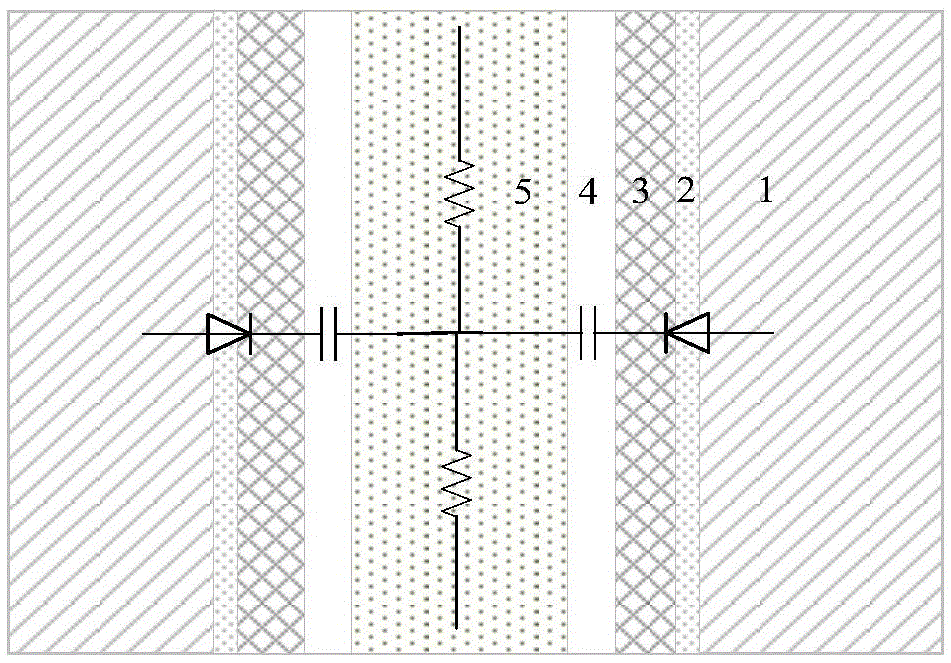

PN junction based through-silicon-via structure and manufacturing method therefor

A fabrication method and technology of PN junction, which are applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as troublesome use and grounding, reduce the use of metal, improve thermomechanical reliability, and achieve high performance. The effect of frequency signal integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

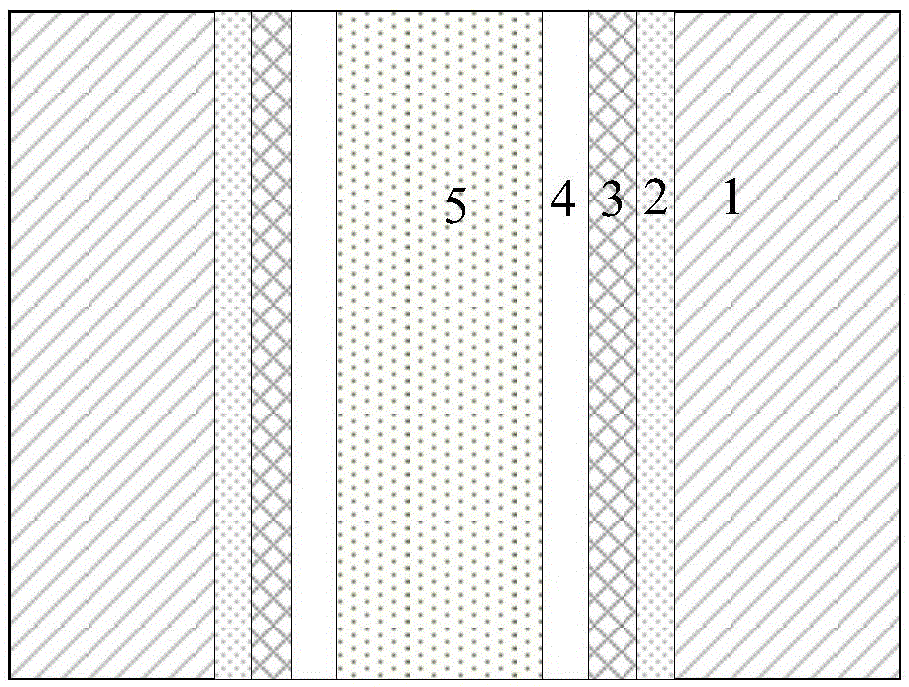

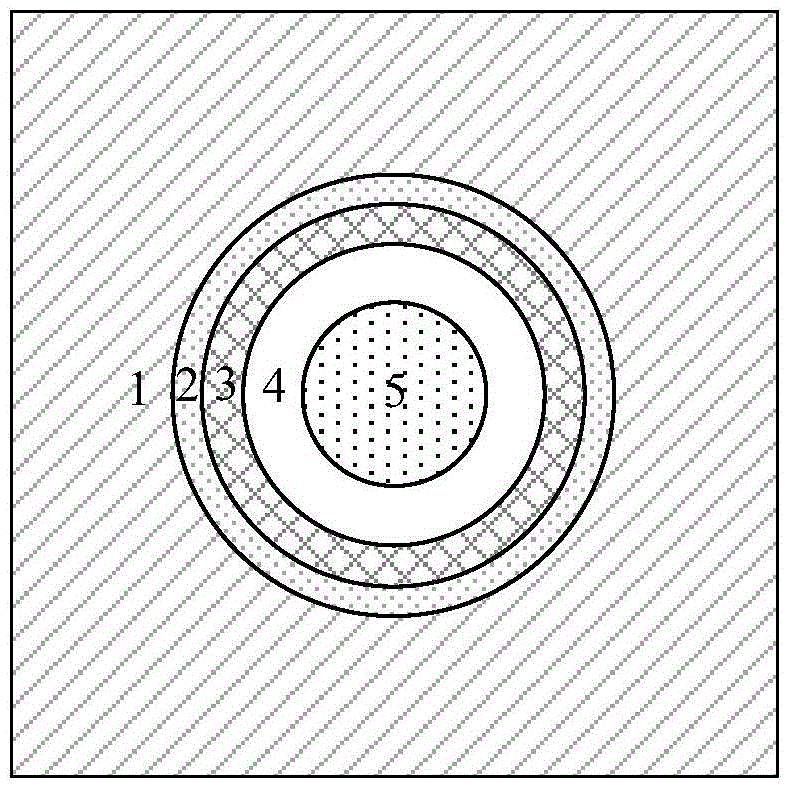

[0058] Step 1. Select a P-type doped silicon substrate as the substrate 1;

[0059] Step 2. Using a reactive ion method to etch through holes that penetrate the upper and lower surfaces of the substrate 1 on the substrate 1, with a radius of 2.6 μm;

[0060] Step 3. Prepare an N-type doped layer 3 on the inner surface of the through hole formed by etching in Step 2;

[0061] Follow the steps below:

[0062] Step 3.1, using a constant surface source diffusion method to deposit impurity atoms on the inner surface of the through hole formed by etching in step 2;

[0063] Step 3.2. Use the finite surface source diffusion method to put the substrate 1 on which the impurity atoms are deposited in step 3.1 into a horizontal diffusion furnace. The furnace temperature of the horizontal diffusion furnace is 950°C, so that the impurity atoms deposited in step 3.1 are further toward The substrate 1 is diffused to form an N-type doped layer 3, and the surface concentration and doping depth of the N...

Embodiment 2

[0068] Step 1. Select a P-type doped silicon substrate as the substrate 1;

[0069] Step 2. Using a reactive ion method to etch through holes that penetrate the upper and lower surfaces of the substrate 1 on the substrate 1, with a radius of 4 μm;

[0070] Step 3. Prepare an N-type doped layer 3 on the inner surface of the through hole formed by etching in Step 2;

[0071] Follow the steps below:

[0072] Step 3.1, using a constant surface source diffusion method to deposit impurity atoms on the inner surface of the through hole formed by etching in step 2;

[0073] Step 3.2. Use the finite surface source diffusion method to put the substrate 1 on which the impurity atoms are deposited in step 3.1 into a horizontal diffusion furnace. The furnace temperature of the horizontal diffusion furnace is 1000°C, so that the impurity atoms deposited in step 3.1 are further directed toward The substrate 1 is diffused to form an N-type doped layer 3, and the surface concentration and doping depth ...

Embodiment 3

[0078] Step 1. Select a P-type doped silicon substrate as the substrate 1;

[0079] Step 2. Using a reactive ion method to etch through holes that penetrate the upper and lower surfaces of the substrate 1 on the substrate 1, with a radius of 6 μm;

[0080] Step 3. Prepare an N-type doped layer 3 on the inner surface of the through hole formed by etching in Step 2;

[0081] Follow the steps below:

[0082] Step 3.1, using a constant surface source diffusion method to deposit impurity atoms on the inner surface of the through hole formed by etching in step 2;

[0083] Step 3.2. Use the finite surface source diffusion method to put the substrate 1 on which the impurity atoms are deposited in step 3.1 into a horizontal diffusion furnace. The furnace temperature of the horizontal diffusion furnace is 1050°C, so that the impurity atoms deposited in step 3.1 are further toward The substrate 1 is diffused to form an N-type doped layer 3, and the surface concentration and doping depth of the N-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com