Drive circuit with ripple current elimination and reduced power consumption

A ripple current and drive circuit technology, applied in the direction of lamp circuit layout, electric light source, light source, etc., can solve the problems of increased power consumption, visual fatigue, increased circuit area and cost, etc., to increase power consumption and eliminate current ripple wave effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The implementation of the present invention is described below with specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification. The present invention can also be implemented or applied through other different specific embodiments.

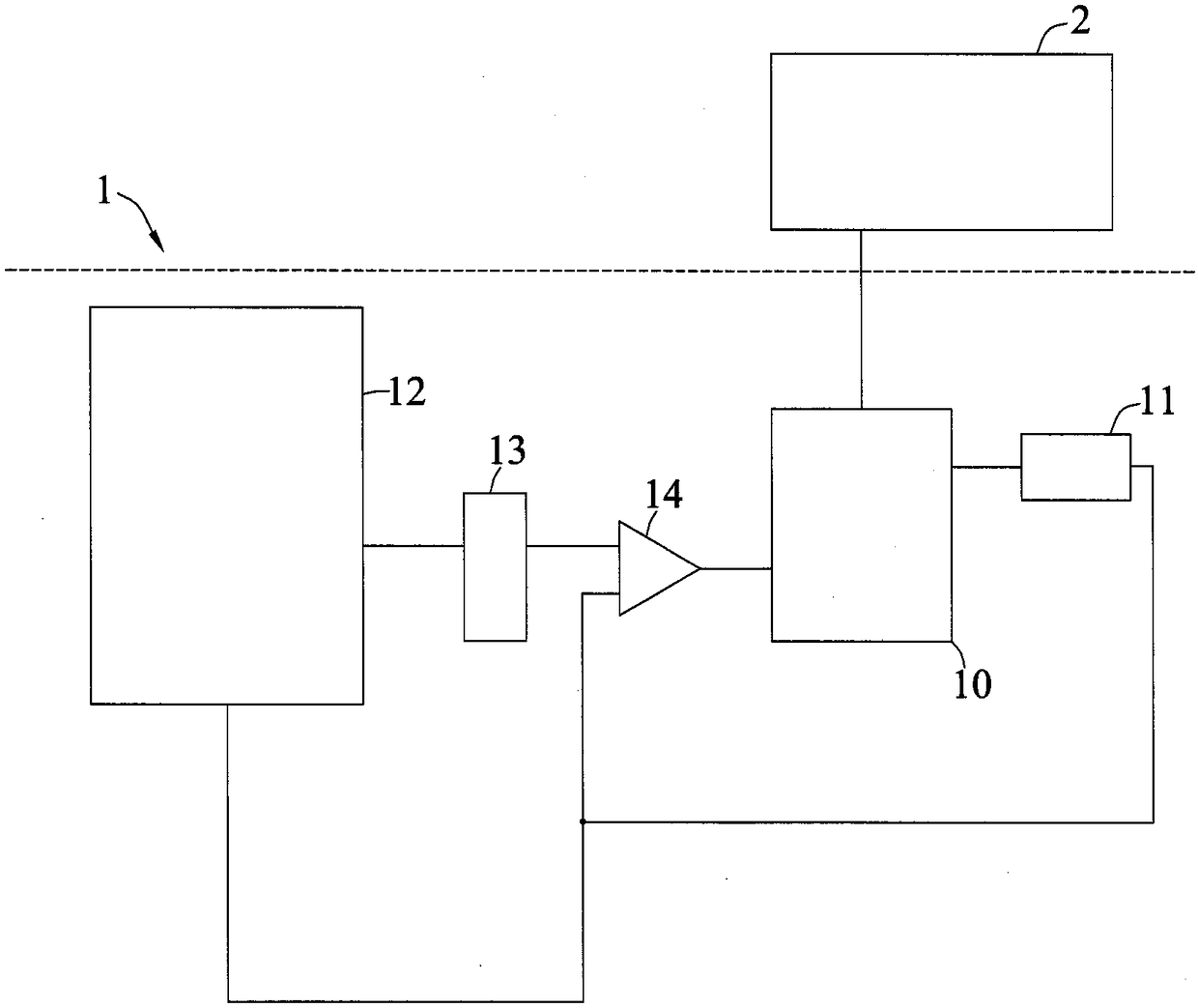

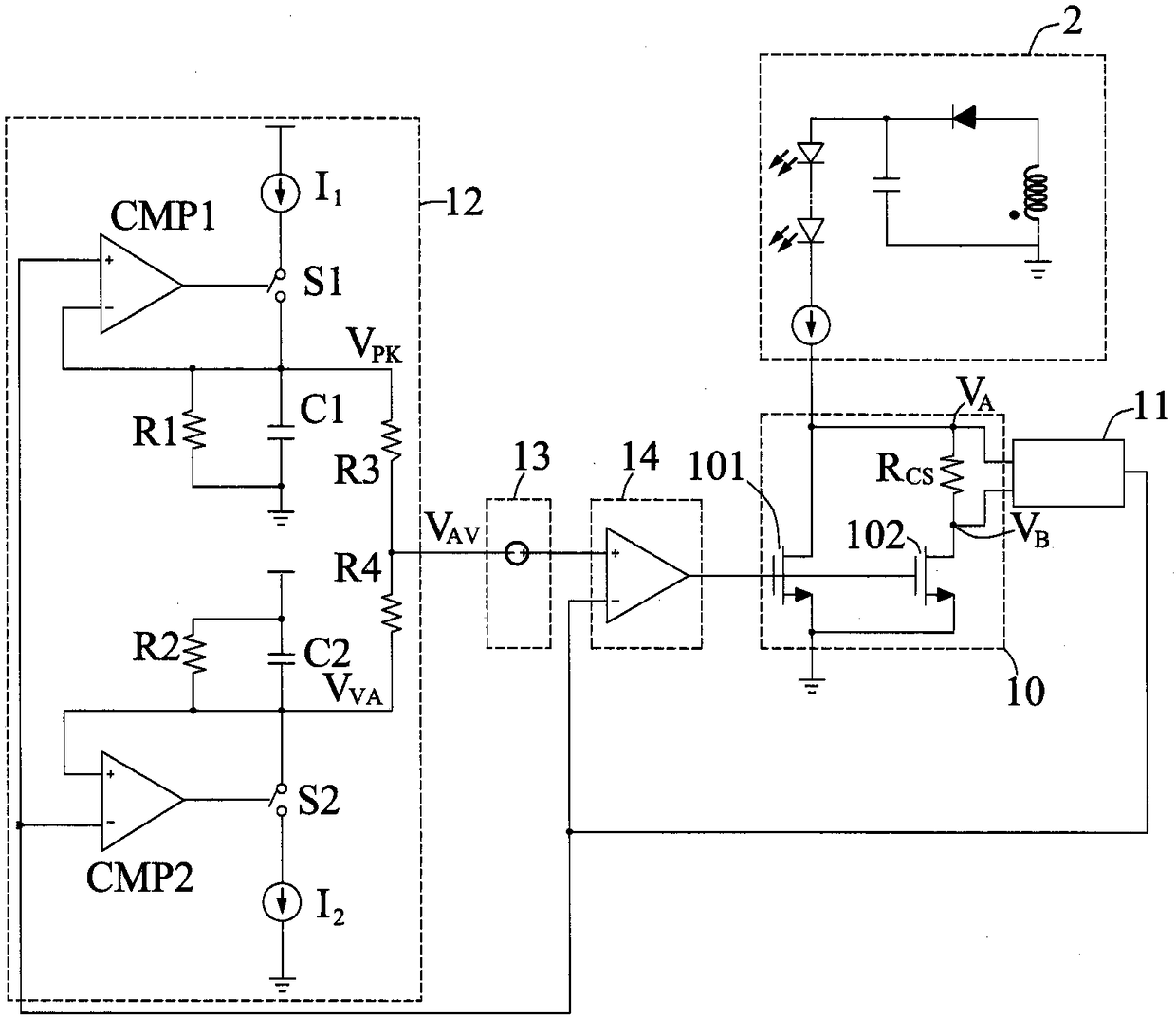

[0046] see figure 1 , which is a schematic structural diagram of a driving circuit with ripple current elimination and power consumption reduction in the present invention. Such as figure 1 As shown, the drive circuit 1 with ripple current elimination and power consumption reduction of the present invention is connected with an external circuit 2 with current ripple, and is characterized in that it includes an output power module 10, a high-side current detection module 11, an average value A sampling module 12 , a bias voltage module 13 and an operational amplifier 14 .

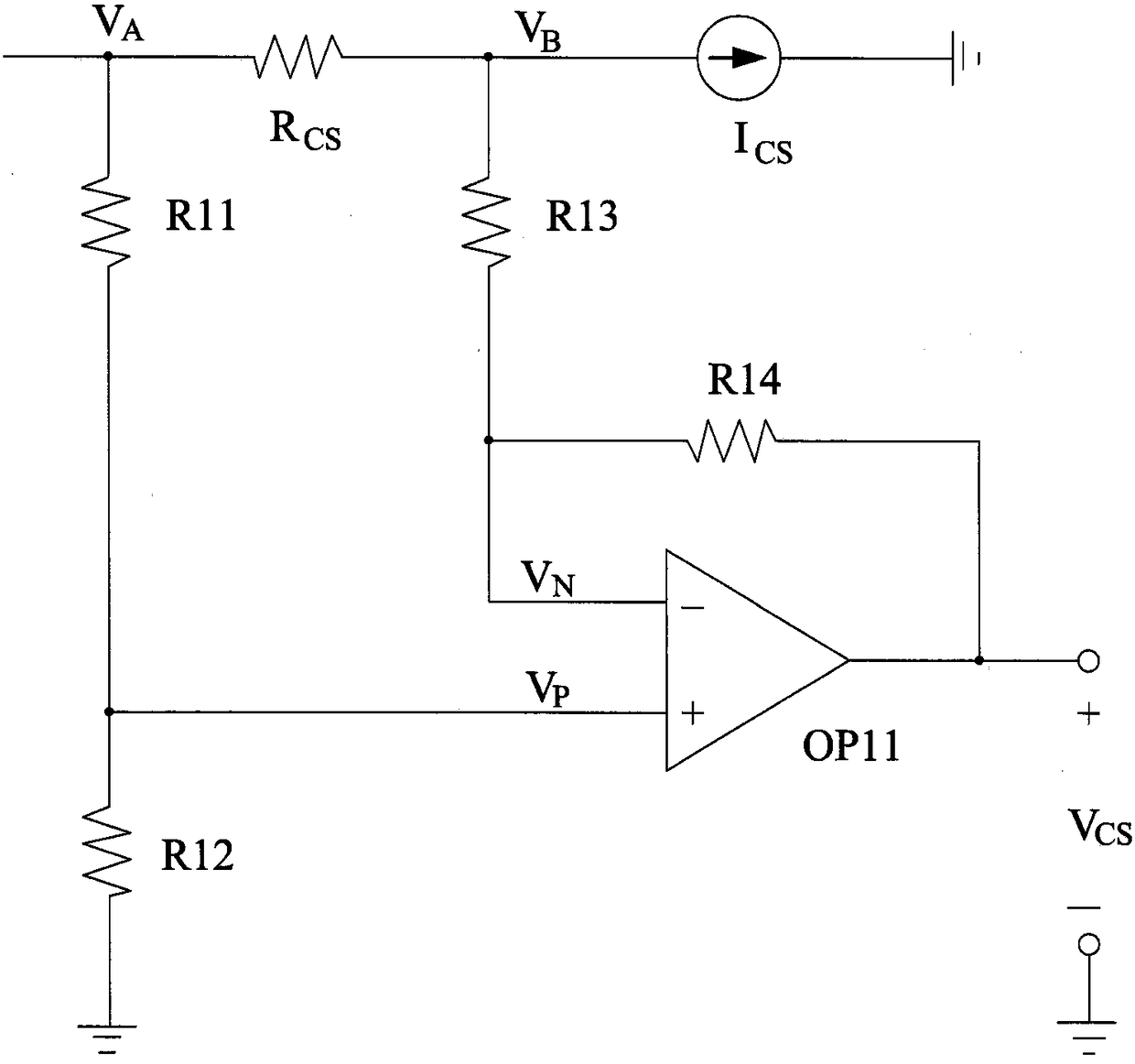

[0047] The output power module 10 is used to be connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com