Striped subsoiling ridge-cleaning straw-mixing combined operation machine

A combined operation machine and subsoiling technology, applied in the field of agricultural machinery, can solve the problems of reduced cultivated land quality, weakened soil buffer capacity, and shallow soil penetration of straw returning to the field, and achieve the effect of preventing burning and enhancing soil organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

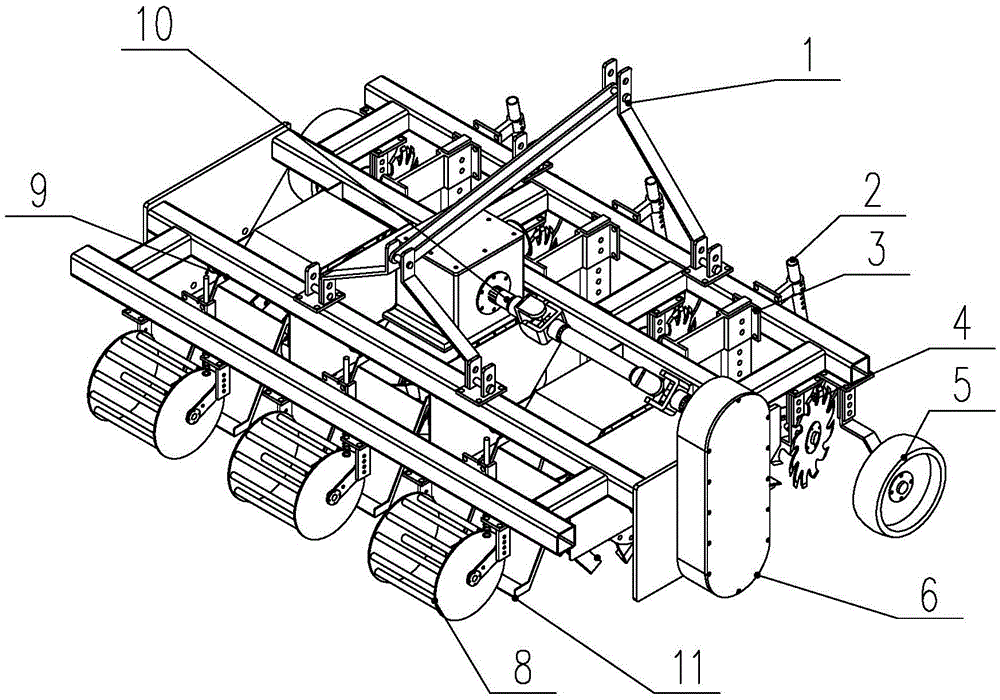

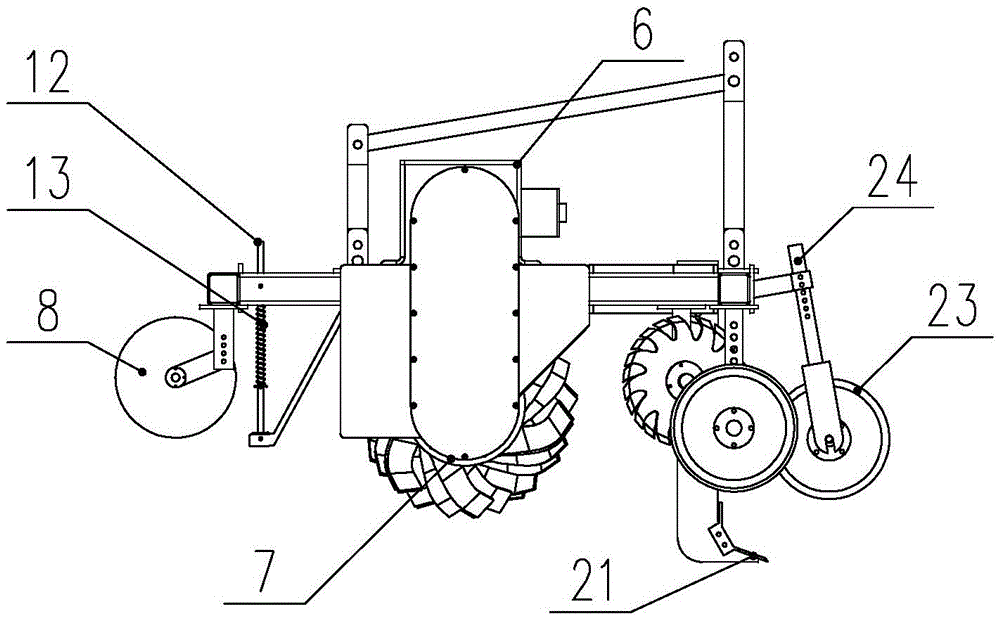

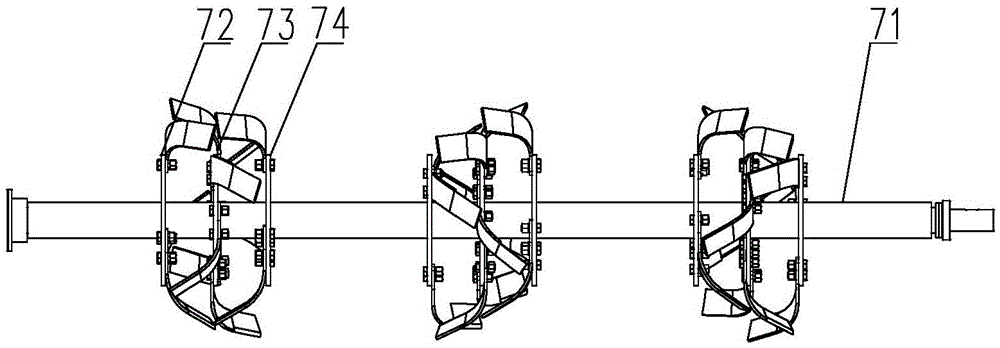

[0035] Example: such as figure 1 As shown, the present invention is a strip subsoiling ridge clearing straw mixing combined operation machine, including a frame 9, a gearbox 6, a transmission device, and a subsoiling device 2 installed on the frame 9 from the working front end to the rear end in sequence. , ridge clearing device 4, mixing device 7 and suppressing device 8, the subsoiling shovel of subsoiling device 2 and the cutter head group of mixing device 7 are placed in the furrow, ridge clearing device 4 is placed at the side of the ridge, and the mixing device The through shaft 71 of 2 is connected the output shaft of gearbox 6 by transmission.

[0036] Such as Figure 4 As shown, the working front end of the subsoiling device 2 is also provided with an anti-winding disc knife 23 . Disc knife 23 is connected at the working front end of subsoiling shovel by knife rest 24. The subsoiling device 2 is to subsoil the mixed furrows. Due to soil compaction, hardening and gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com