High-water textured protein processing method for wheat

A processing method and high-moisture technology, applied in the fields of vegetable protein processing, food ingredients, food science, etc., can solve the problems of high viscosity of wet gluten, energy waste, dense texture and difficult to mix with other materials, etc., to achieve good results and save energy costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

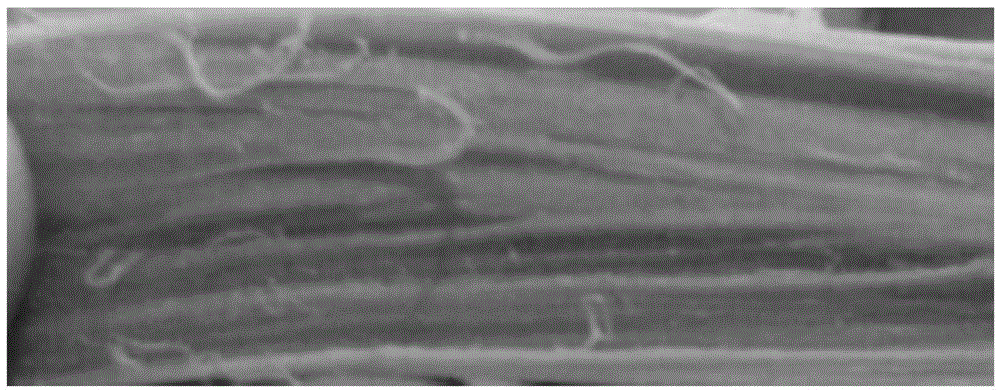

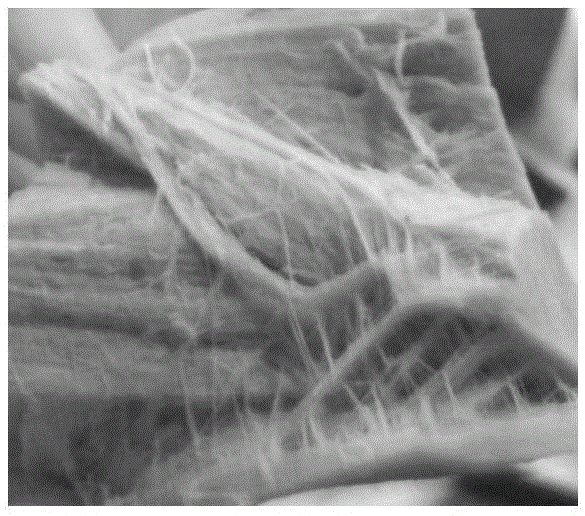

Image

Examples

Embodiment 1

[0027] Embodiment 1: pure wheat protein processing method

[0028] Using wet gluten, a by-product of wheat starch processing, as the main processing raw material, adding gluten powder to prepare high-moisture textured protein, including the following steps:

[0029] Chop and mix: After washing 1 mass part of wheat wet gluten twice, shake off the surface free water and pour it into a chopping machine, add 1 mass part of gluten powder, chop and mix for 5 minutes until evenly mixed, then place in ground meat Twist into strips in the machine.

[0030] Organization: Feed the strip filling into the extruder with cooling extension, set the extrusion temperature at 60-90-160-130-120°C, the screw speed at 300r / min, the extrusion die head temperature The temperature is 130°C, the pressure is 4.5MPa, and the temperature in the cooling section is 60°C.

[0031] Cutting: The material coming out of the extruder is cut to 10cm with a cutter, which is the high-moisture textured protein prod...

Embodiment 2

[0035] Example 2: Processing method of high-moisture textured protein from grain bean

[0036] A method for processing grain and bean high-moisture textured protein, using wet gluten as a main processing raw material by-product of wheat starch processing, adding peanut protein and pea protein to prepare high-moisture textured protein, comprising the following steps:

[0037] Chop and mix: wash 1 mass part of wheat wet gluten three times, shake off the surface free water and pour it into a chopping machine (moisture content 50%), add 0.5 mass part of peanut protein powder and 0.5 mass part of pea protein powder , chopped and mixed for 5 minutes until evenly mixed, then placed in a meat grinder and twisted into strip-shaped fillings (moisture content 50%).

[0038] Texturization: Feed the strip filling into the extruder with cooling extension, set the extrusion temperature to 70-100-170-140-130°C, the screw speed to 300r / min, and the temperature of the extrusion die The tempera...

Embodiment 3

[0041] Embodiment 3: Wheat high-moisture textured protein processing method

[0042] A method for processing wheat high-moisture textured protein, using wheat starch processing by-product wet gluten as the main processing raw material, adding soybean protein powder to prepare high-moisture textured protein, comprising the following steps:

[0043] Chop and mix: wash 3 parts by mass of wheat wet gluten for 3 times, shake off the free water on the surface and pour it into a chopping machine (moisture content 50%), add 3 parts by mass of soybean protein powder, chop and mix for 5 minutes until evenly mixed Finally, place it in a meat grinder and twist it into strip-shaped stuffing (moisture content 50%).

[0044] Organization: Feed the strip filling into the extruder with cooling extension, set the extrusion temperature to 70-100-170-140-130°C, the screw speed to 200r / min, the temperature of the extrusion die at 120°C,

[0045] Cutting: The material coming out of the extruder i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com