Low-sugar peach syrup and preparation method thereof

A technology for pear paste and pear juice, which is applied to the field of low-sugar pear paste and its preparation, can solve the problems of difficult industrial production, general taste of pear paste, and many process steps, and achieves the effects of low cost, simple and feasible process steps, and sweet and delicious taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

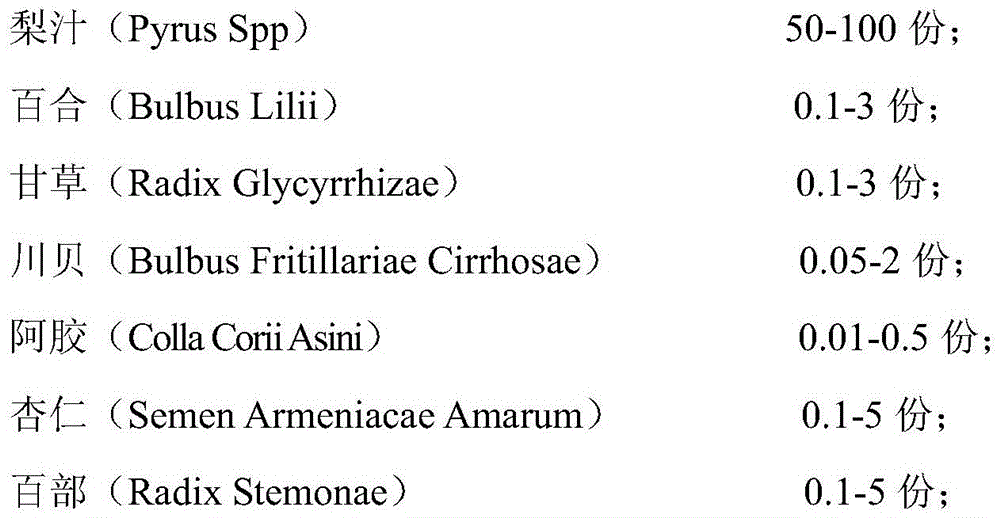

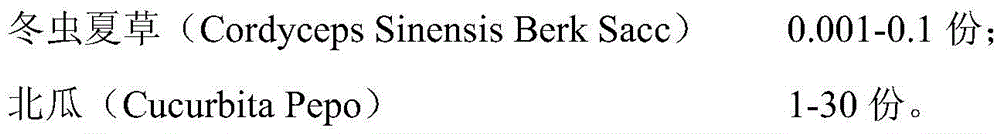

Method used

Image

Examples

Embodiment 1

[0041] After cleaning the pears, take 90g of pure pear juice after squeezing the juice, add 0.3g of lily, 0.2g of licorice, 0.1g of Chuanbei, 0.2g of almond, and 0.2g of Baibu respectively. After the first boiling, cool, precipitate, Filtration, boiling temperature is 800 ℃, time is 4 hours. In the filtered pear juice, add 0.02g of donkey-hide gelatin, 0.01g of cordyceps sinensis, 10g of pumpkin, if necessary, add 2g of mushroom mother, mix and then boil for the second time, cool, settle, and collect the juice. 700°C for 3 hours. That is the pear paste sample 1#.

Embodiment 2

[0043] After cleaning the pears, take 80g of pure pear juice after squeezing the juice, add 0.5g of lily, 0.5g of licorice, 0.2g of Chuanbei, 0.3g of almond, and 0.3g of Baibu, and cool, precipitate, Filtration, boiling temperature is 1000 ℃, time is 3 hours. In the filtered pear juice, add 0.03g of donkey-hide gelatin, 0.02g of cordyceps sinensis, and 8g of pumpkin, and if necessary, add 3g of mushroom mother, mix and then boil for the second time, cool, settle, and collect the juice. 800°C for 4 hours. That is, pear paste sample 2#.

Embodiment 3

[0045] After cleaning the pears, take 60g of pure pear juice after squeezing, add 1g of lily, 1g of licorice, 0.5g of Chuanbei, 1g of almond, and 1g of Baibu respectively. After the first boiling, cool, precipitate, filter, and boil The temperature is 1200°C and the time is 2 hours. In the filtered pear juice, add 0.1g of donkey-hide gelatin, 0.04g of cordyceps sinensis, 15g of pumpkin, and 10g of mushroom mother if necessary, mix and then boil for the second time, cool, settle, and collect the juice. 800°C for 3 hours. That is the pear paste sample 3#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com