Circuit board cutting machine and cutting method

A circuit board and cutting machine technology, applied in cocoa, grain processing, food science, etc., can solve the problems of increased equipment cost, inconvenient installation, and low crushing efficiency, and achieve the effect of preventing dust and facilitating disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

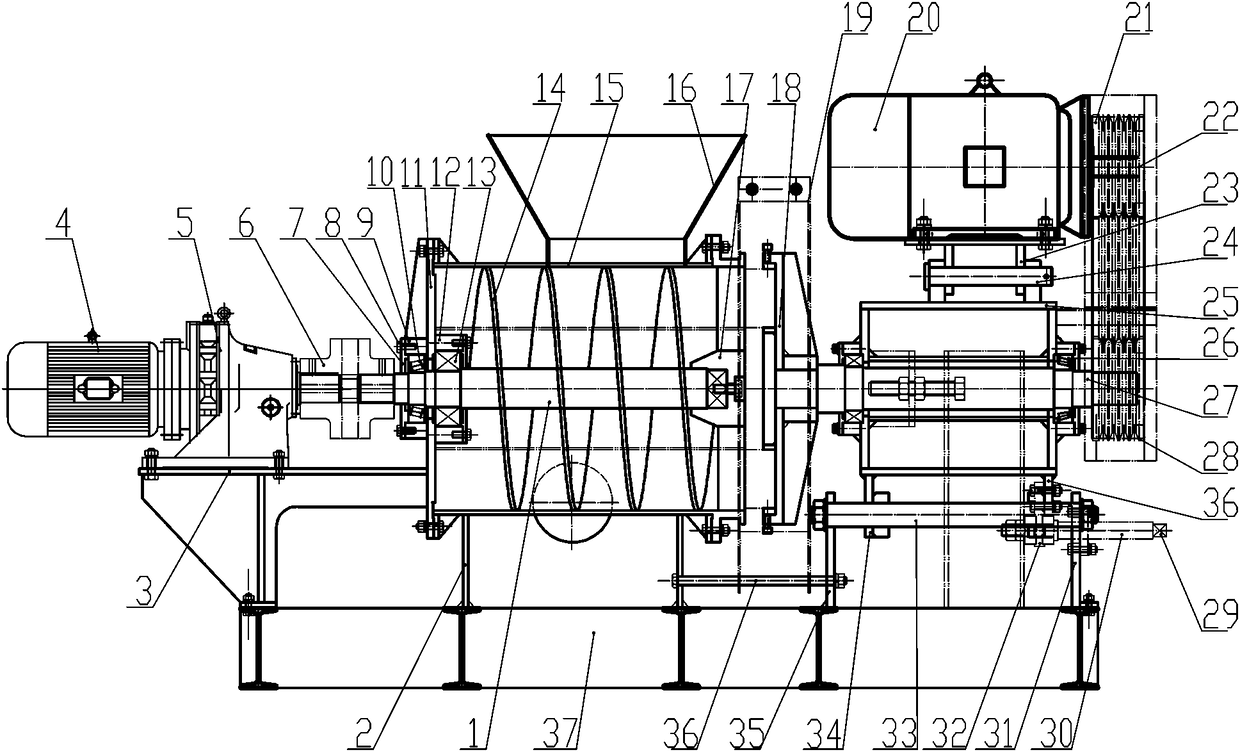

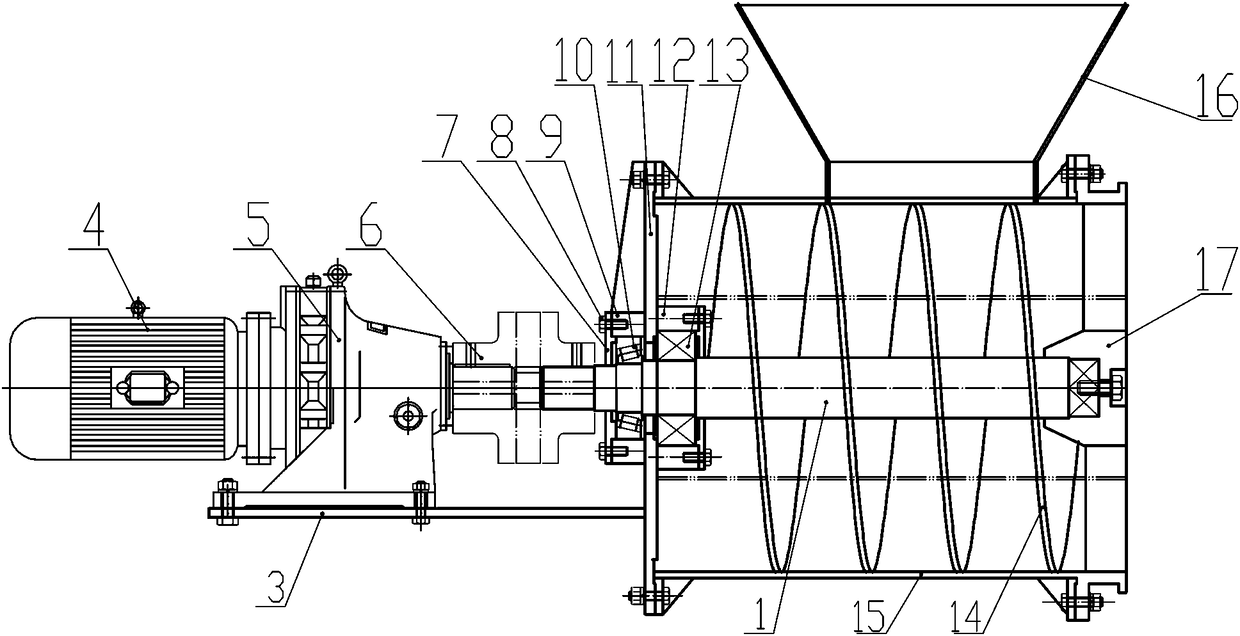

[0050] The method for cutting a circuit board by using a circuit board cutting machine comprises the following steps:

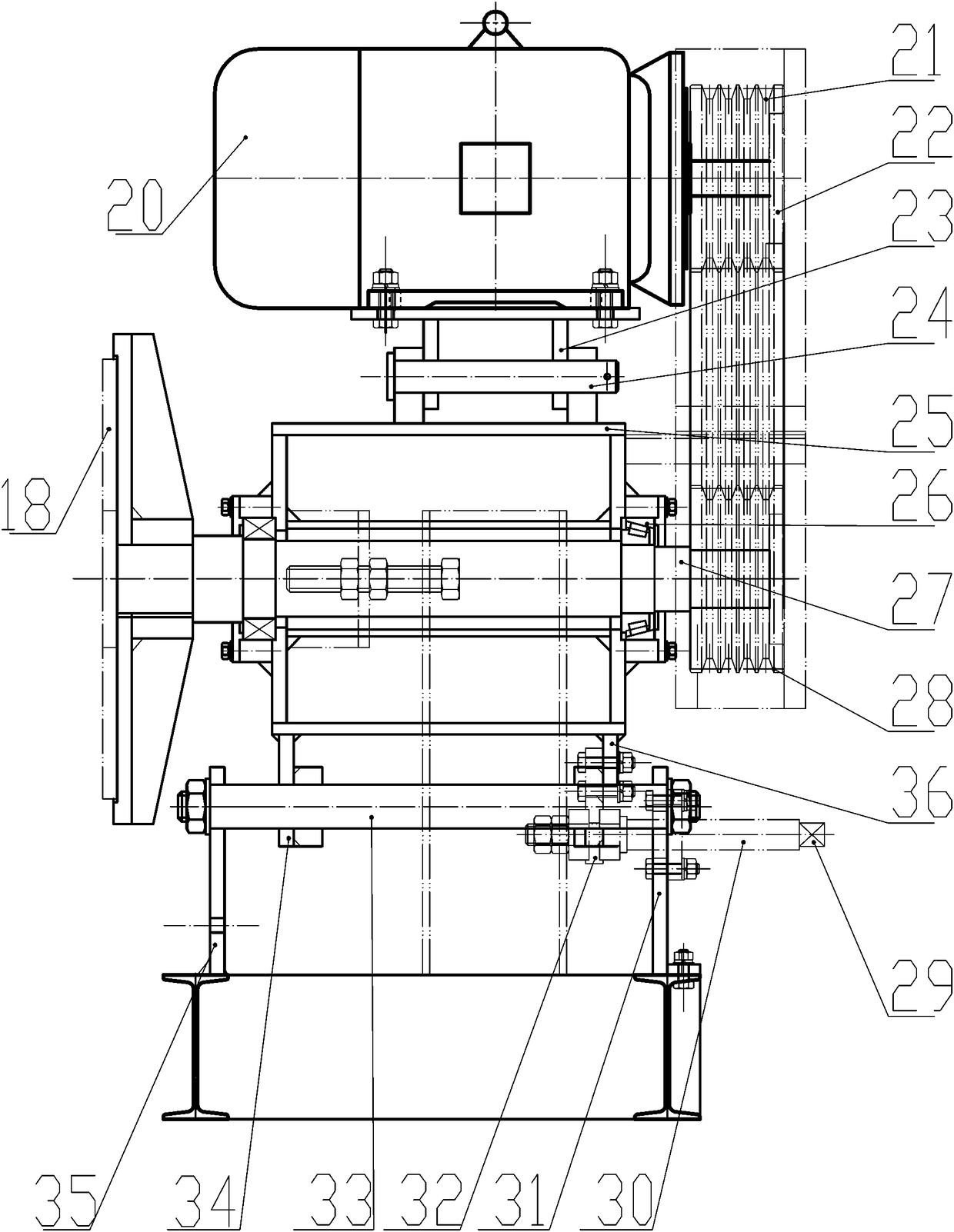

[0051] 1) Start the screw-in motor 4 and the high-speed motor 20 respectively, and then put the waste circuit boards from the feeding funnel 16 into the inside of the feeding barrel 15, and the screw-in spindle 1 inside the feeding barrel 15 drives the pressing screw structure 14 to remove the waste circuit boards. The circuit board is transported to the right side of the feeding cylinder 15, and reaches the low-speed cutting disc 17 for preliminary cutting of the waste circuit board, and presses the waste circuit board to the wear-resistant toothed disc 18;

[0052] 2) Driven by the high-speed motor 20, the wear-resistant toothed disc 18 performs secondary grinding and crushing on the waste circuit board, and injects water into the inside of the feeding cylinder 15 through the feeding funnel 16, and the water is pushed by the pressing screw structure 14 Go d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com