Fast dehydration type straw cleaning mechanism capable of recycling cleaning water

A fast dehydration and cleaning mechanism technology, applied in the field of cleaning, can solve the problems of time-consuming and complicated manual management, and achieve the effects of reducing water pollution, speeding up dehydration and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

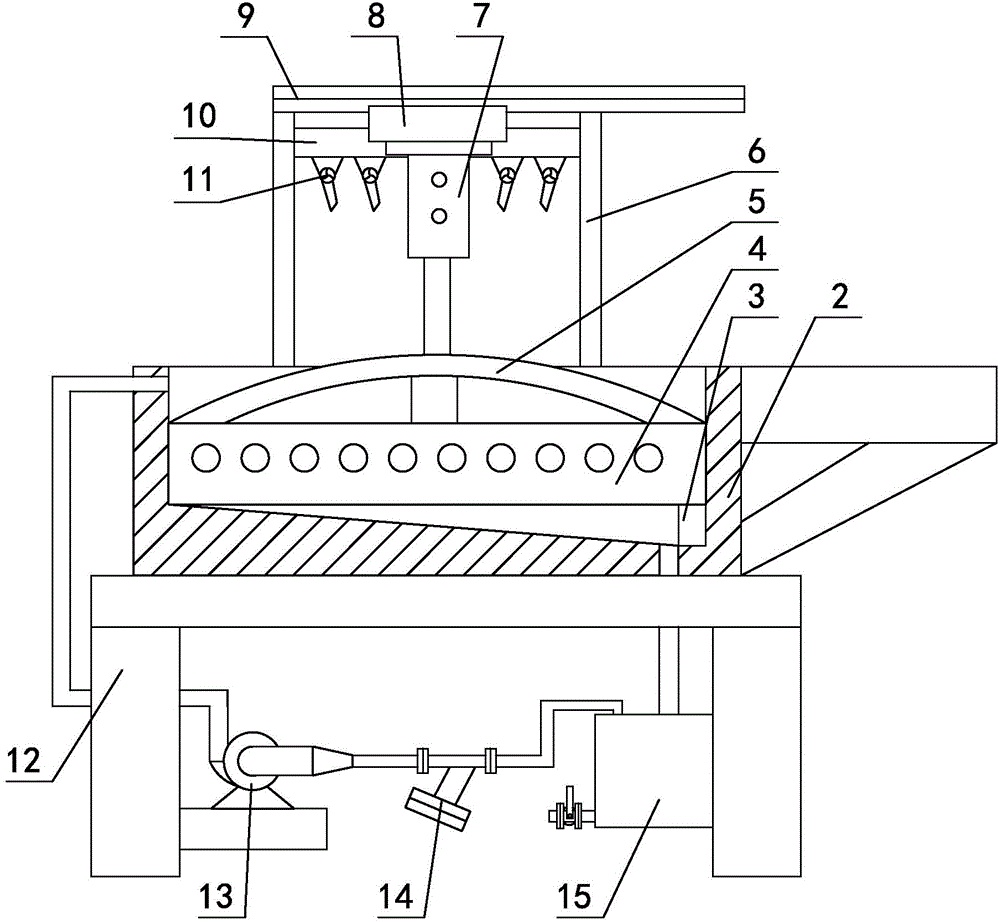

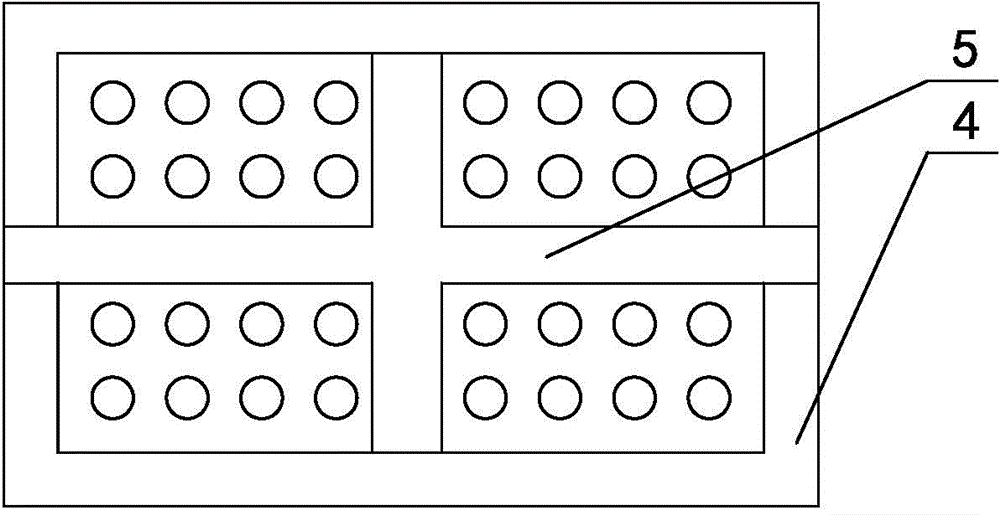

[0022] like figure 1 , figure 2 As shown, the fast dehydration straw cleaning mechanism with flushing water recovery includes a cleaning tank 2, and a cleaning tank 4 for placing straws that moves up and down in the cleaning tank 2 is provided. The bottom and side walls of the cleaning tank 4 are provided with There is a water leakage hole, and the inner side wall of the cleaning tank 2 at the bottom of the cleaning tank 4 is fixed with a stopper 3 for preventing the bottom of the cleaning tank 4 from contacting the bottom of the cleaning tank 2, and a bracket 6 is installed on the top of the cleaning tank 2, and the bracket 6 is set horizontally There is a slide rail 9 on which a slider 8 sliding left and right is installed, and the bottom of the slider 8 is installed with a power mechanism 7 for cleaning the tank 4 to move up and down, and the right side wall of the cleaning tank 2 is provided with an unloading table for convenient unloading 1. The slide rail 9 extends to ...

Embodiment 2

[0026] A change is made on the basis of Embodiment 1, the power mechanism 7 is a cylinder, the cylinder body of the cylinder is installed on the bracket 6, and the piston rod of the cylinder is connected with the handle 5; the inclination angle of the inclined surface is changed to 20 degrees. Others are the same as embodiment one.

Embodiment 3

[0028] Changes are made on the basis of Embodiment 1. The power mechanism 7 includes a screw and a nut that cooperate with each other. The lower end of the screw is vertically fixed on the handle 5, and the upper end passes through the bracket 6 independently. The nut is arranged above the bracket 6. The gear set is connected with the power transmission of the motor; the inclination angle of the inclined surface becomes 16 degrees. Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com