Segregation-resistant circular stock bin

An anti-segregation and silo technology, which is applied in the field of anti-segregation silos, can solve the problems that the length of the feeding channel cannot be adjusted, the material feeding is not blocked, and the feeding is affected, so as to achieve smooth and uniform feeding and reduce The effect of segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

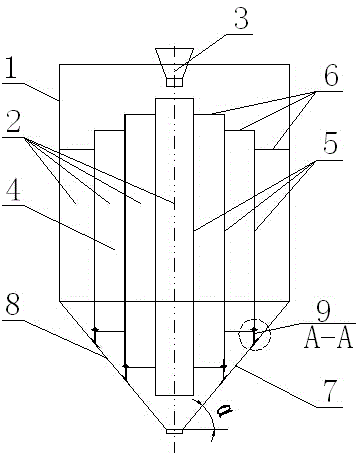

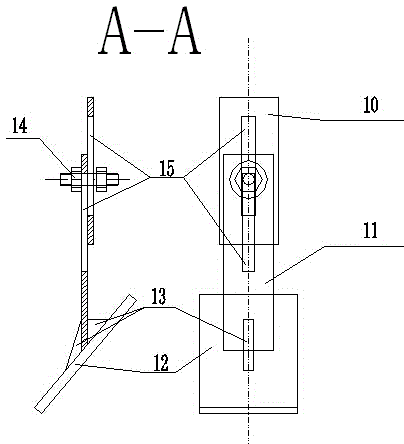

[0017] The present invention includes a feeding port 3 located on the upper part of the silo body 1 and a frustum outlet 8 located at the lower part of the silo body 1. The silo body 1 is provided with an anti-segregation device 4, and the anti-segregation device 4 includes The feature is that the concentric cylinder 5 and the partition plate 6 are divided into several feeding channels 2. The anti-segregation device 4 stands on the inclined surface of the frustum body 8 by the support frame 9 located at the lower part. The support frame consists of an upper sliding support plate 10 The lower sliding support plate 11 is fixed to the bottom of the anti-segregation device 4 by bolts and nuts, and the angle between the frustum section 7 of the frustum body 8 and the horizontal plane should be greater than the maximum angle of repose of the material.

[0018] The anti-segregation device 4 is divided into several feeding channels 2 by several concentric cylinders 5 and partitions 6 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com