A ternary boride reinforced Ti(c,n)-based cermet material and its preparation method

A technology of ternary borides and ceramic materials, which is applied in the field of metal matrix composite materials, can solve the problems of excessive particle size, insufficient liquid phase filling, and deterioration of material properties, so as to achieve enhanced wear resistance and toughness, and uniform surface properties Consistent, friction-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

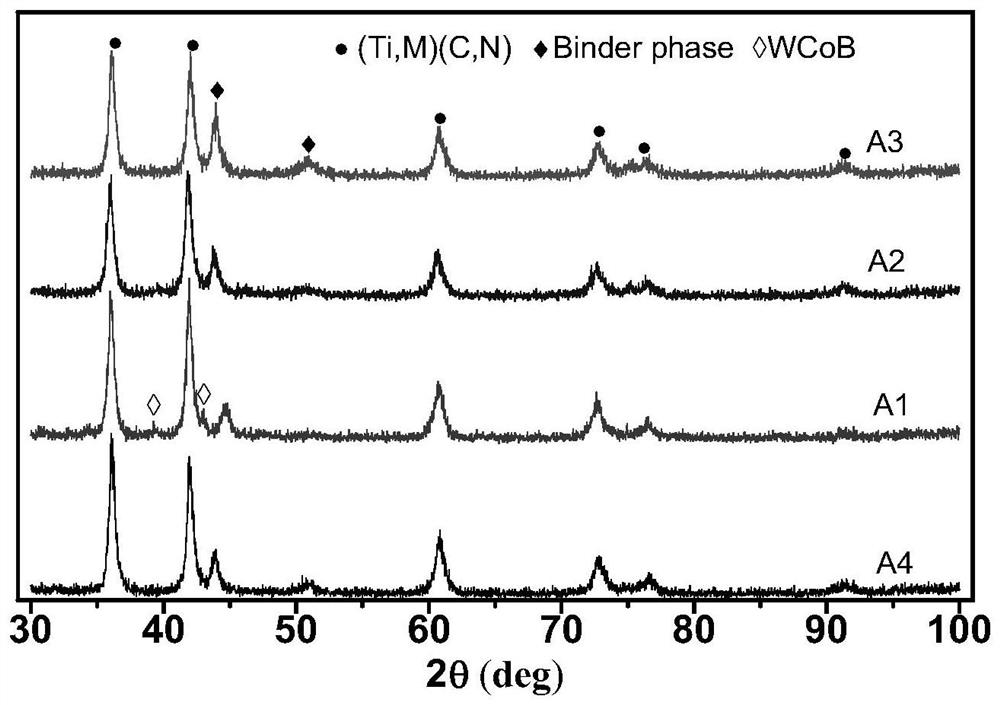

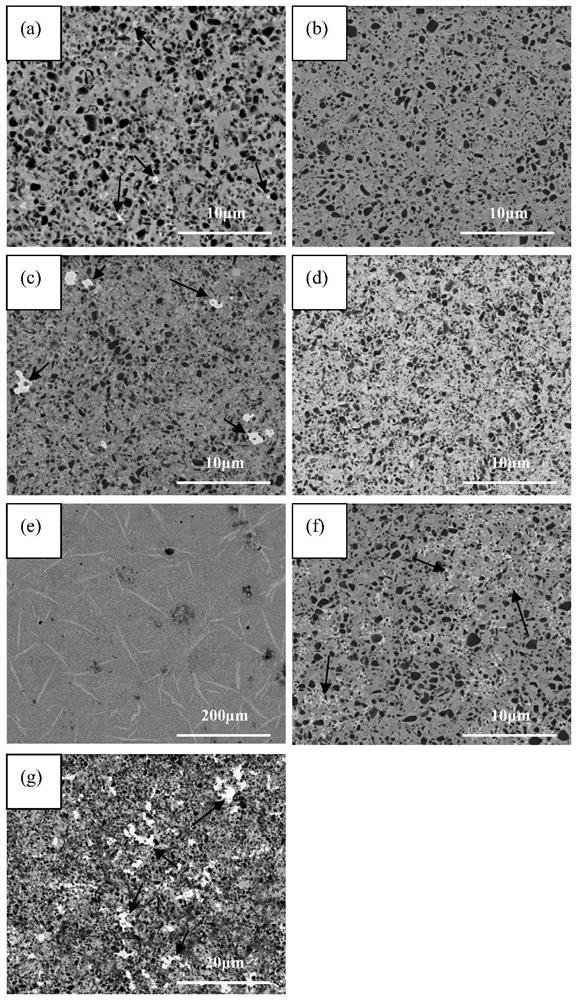

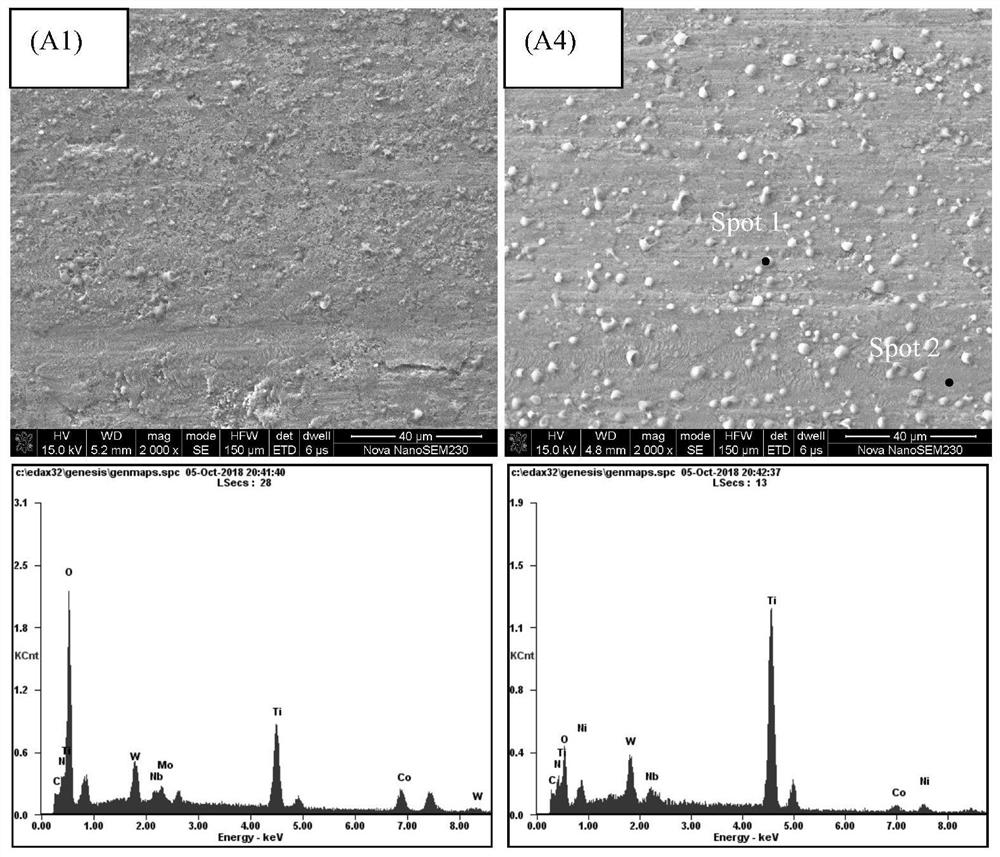

Embodiment 1

[0074] Weigh Ti(C,N) 49g, WC 16g, MoC 4g, TaC 8g, WB 2 3g, Co 11g, Ni 9g, carbon powder 1g, molding agent (paraffin) 4g; the particle sizes of each powder are Ti(C,N) 2.28μm, WC 3.66μm, MoC 2μm, TaC 3.4μm, WB 2 0.5μm, Co 7.5μm, Ni 8.9μm, carbon powder 11.4μm. Carbide balls are grinding balls, the ball-to-material ratio is 5:1, absolute ethanol is 70mL, and the weighed 3gWB 2 Mix the powder with 20mL of absolute ethanol and place in a closed container, which will contain WB 2 Place the container of the mixed solution with absolute ethanol in the ultrasonic cleaner, place the temperature measuring instrument in the water outside the container, turn on the ultrasonic cleaner, and when the temperature reaches 40°C, take out the container, replace it with cold water, and then put it into the container to continue Ultrasound, and then repeat the operation of changing the cold water when the temperature reaches 40°C until the total ultrasonic time reaches 24h. The mixing time is...

Embodiment 2

[0077] Weigh respectively Ti(C,N) 51g, WC 16g, MoC 4g, TaC 8g, WB 2 1g, Co 11g, Ni 9g, carbon powder 1g, molding agent 4g; the particle size of each powder is Ti(C,N) 2.28μm, WC 3.66μm, MoC 2μm, TaC 3.4μm, WB 2 0.5μm, Co 7.5μm, Ni 8.9μm, carbon powder 11.4μm. Mix the weighed 1g of WB2 powder with 20mL of absolute ethanol, put it in a closed container, place the container containing the mixed solution of WB2 and absolute ethanol in an ultrasonic cleaner, and place the temperature measuring instrument in the water outside the container , Turn on the ultrasonic cleaning machine, when the temperature reaches 40°C, take out the container, replace with cold water, put it into the container to continue ultrasonication, and then repeat the operation of replacing cold water when the temperature reaches 40°C until the total ultrasonic time reaches 24h. The cemented carbide ball is a grinding ball, the ball-to-material ratio is 5:1, add 50mL of absolute ethanol, and then add the disper...

Embodiment 3

[0080] Weigh 51g of Ti(C,N), 16g of WC, 4g of MoC, 8g of TaC, 1g of MoB, 11g of Co, 9g of Ni, 1g of carbon powder, and 4g of forming agent; the particle diameters of each powder are respectively Ti(C,N ) 2.28 μm, WC 3.66 μm, MoC 2 μm, TaC 3.4 μm, MoB 3 μm, Co 7.5 μm, Ni 8.9 μm, carbon powder 11.4 μm.

[0081] Mix the weighed 1g of MoB powder with 20mL of absolute ethanol, put it in a closed container, place the container containing the mixed solution of MoB and absolute ethanol in an ultrasonic cleaner, and place the temperature measuring instrument in the water outside the container , Turn on the ultrasonic cleaning machine, when the temperature reaches 40°C, take out the container, replace with cold water, put it into the container to continue ultrasonication, and then repeat the operation of replacing cold water when the temperature reaches 40°C until the total ultrasonic time reaches 24h. The cemented carbide ball is a grinding ball, the ball-to-material ratio is 5:1, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com