Fixing structure and mode of glass fiber pathway bushing brick

A technology of glass fiber and fixed structure, applied in the field of glass fiber passage bushing brick fixing structure and its fixing method, can solve the problems of affecting the uniformity of molten glass, operator safety accidents, cracks in bushing bricks, etc., and achieve fast and accurate The effect of replacement installation, reduction of operators, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

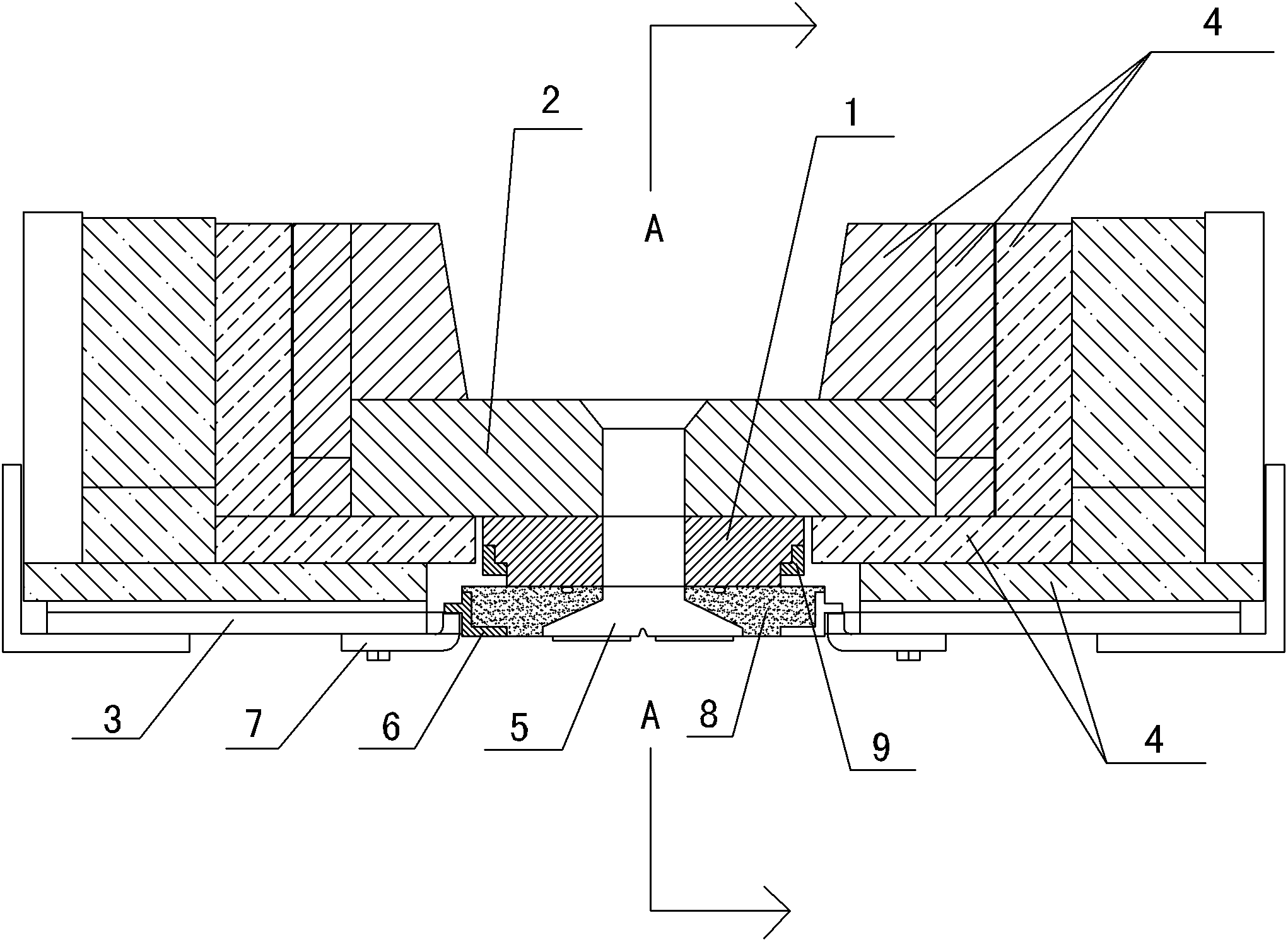

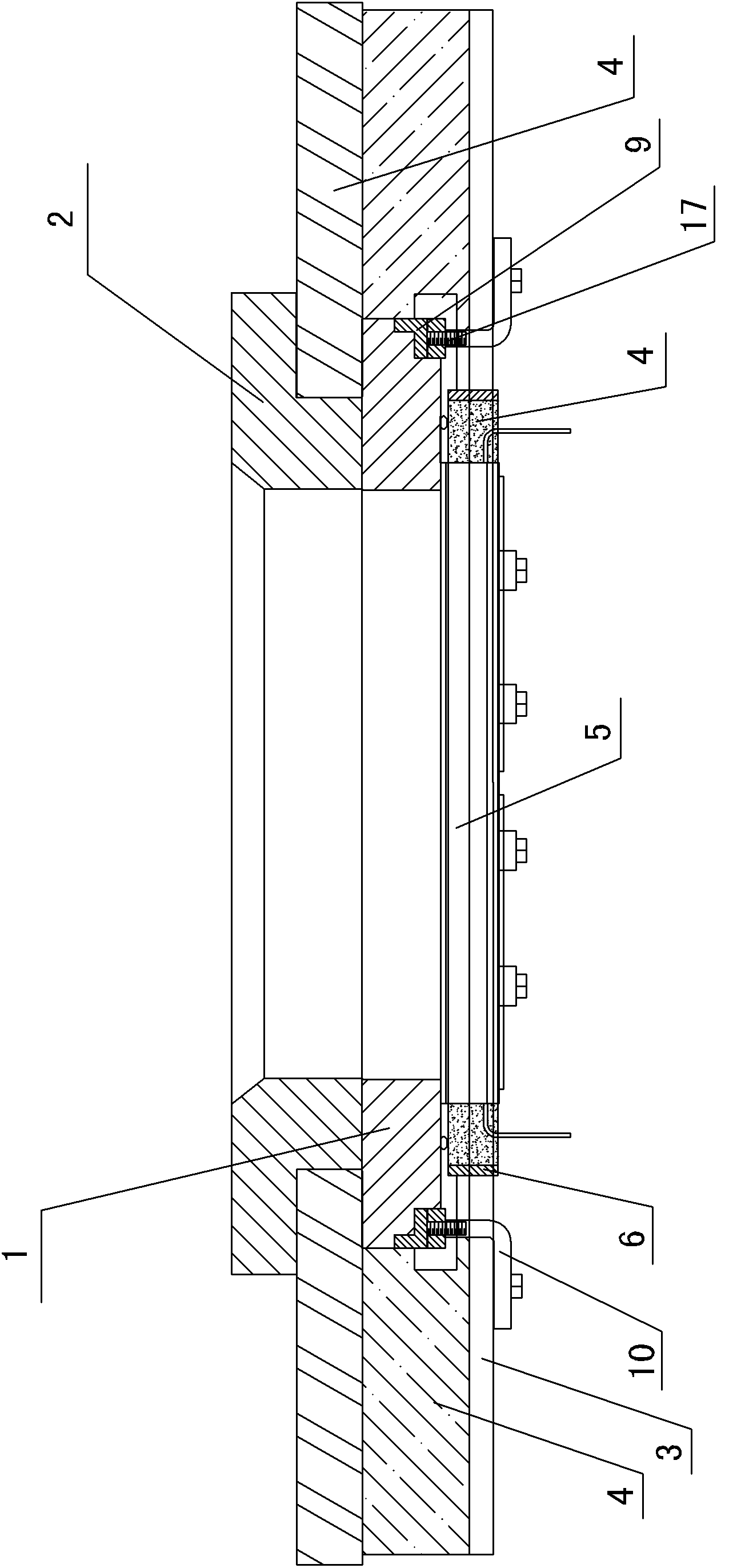

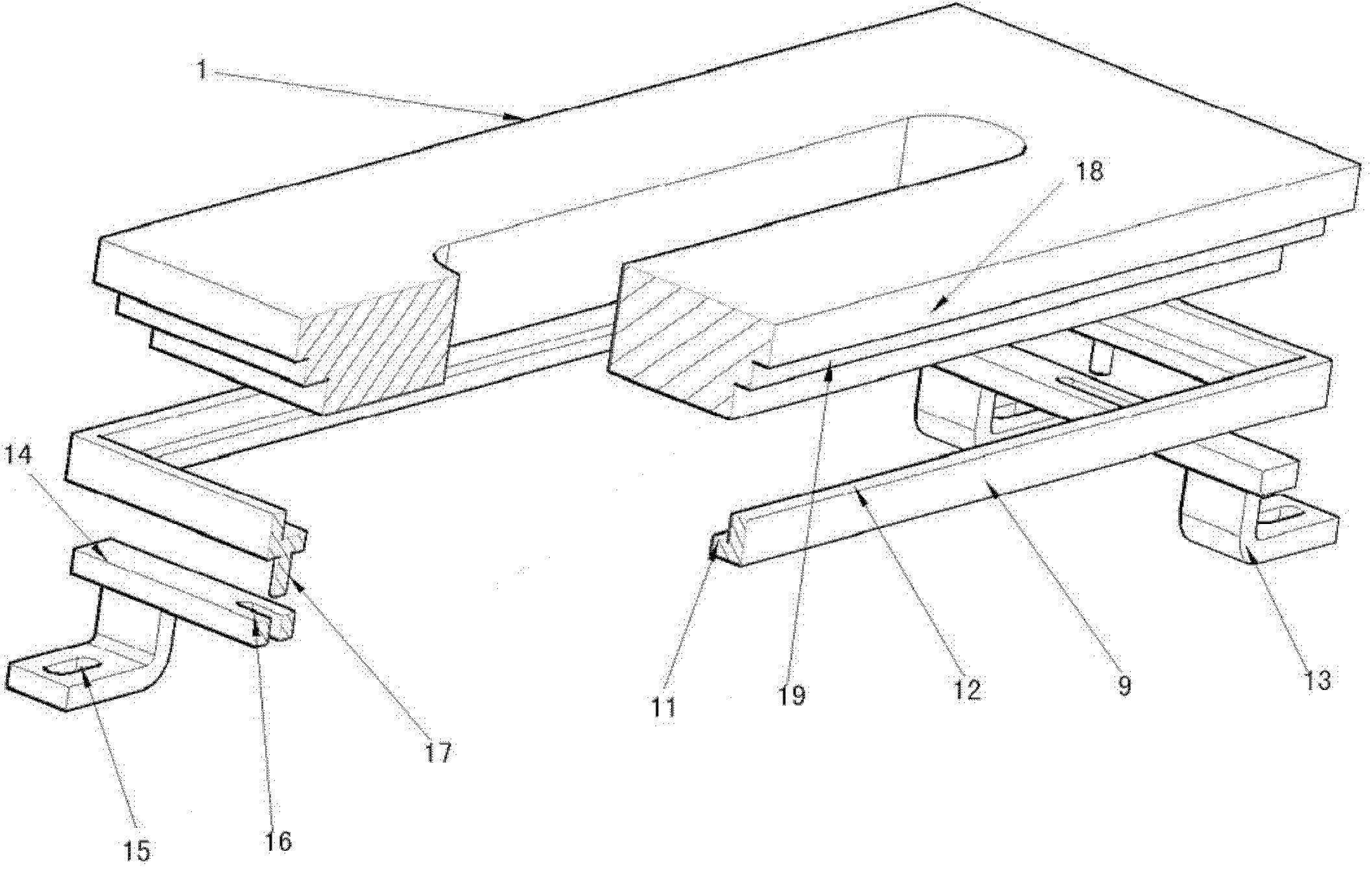

[0029] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

[0030] Such as Figure 1~3 As shown, the fixed structure of the glass fiber channel slab brick includes a slab system, a channel main body, and a slab brick 1 installed between the slab system and the channel main body. The channel main body includes a flow brick 2, a channel substrate 3 and a refractory brick 4. , The slat system includes slat 5, slat frame 6, slat frame support hook 7 and casting material 8. slat brick frame 9 is placed at the bottom of slat tile 1, and the outer periphery of slat tile 1 is double stepped Structure, the top periphery of the slat brick frame 9 is a corresponding single-layer stepped structure, and the bottom of the two ends of the slat brick frame 9 are connected with slat brick frame holders 10, and the slat brick frame 9 is fixed by the slat brick frame holders 10 On the lower surface of the via substrate 3.

[0031]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com