High-strength hard polyurethane foamed plastic and preparation method thereof

A technology of rigid polyurethane and foam plastics, applied in the manufacture and application of rigid polyurethane foam plastics, in the field of polyurethane, can solve the problems of low connection strength and insufficient structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

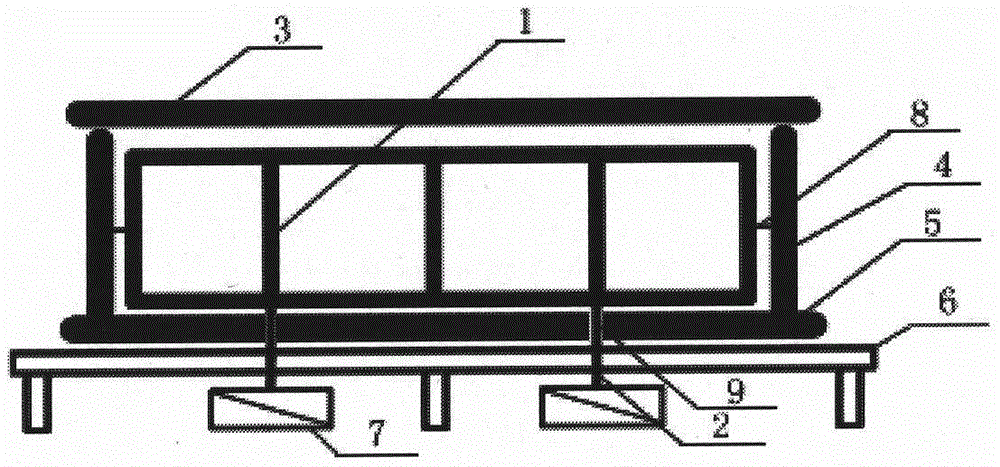

[0033]This example explains the preparation method of the flexural test block used for production testing. When manufacturing other products, the external dimensions of the mold, the type and specification of the material used for the metal frame, and the density of the rigid polyurethane foam body need to be based on the force of the product being produced. The calculation and adjustment of the situation, the preparation method, steps and principle are the same, and the corresponding adjustment can be made according to the preparation process of the following example.

[0034] (1) Product specifications: 550MM*150MM*150MM

[0035] (2) The isocyanate and polyether polyol are combined to make foaming raw materials, and the flame retardant grade is B1.

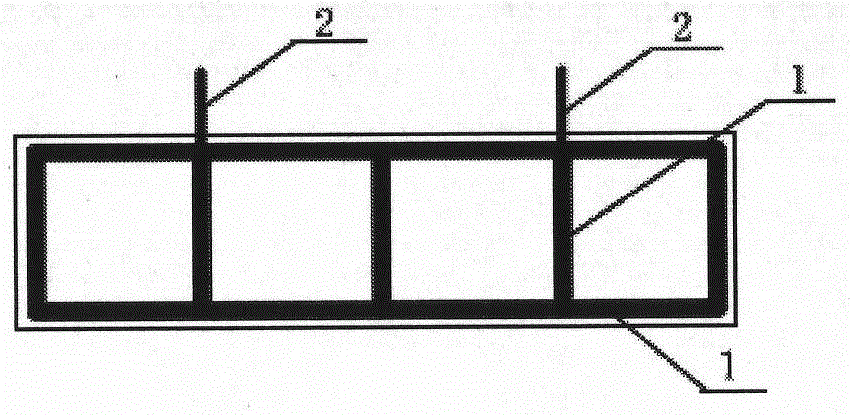

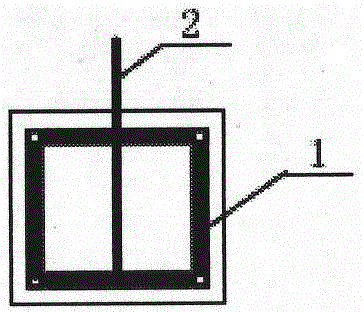

[0036] (3) Weld the 20MM*20MM*1.0MMQ235 steel square tube into the frame (1).

[0037] (4) Two stainless steel materials are made into bolt-shaped embedded parts (2).

[0038] (5) The aluminum alloy material is made into 4 lon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com