Stone polishing powder

A technology for polishing powder and stone, which can be applied to polishing compositions containing abrasives and other directions, and can solve the problems of insufficiency, environmental pollution, dry luster, etc.

Active Publication Date: 2016-06-08

SHANGHAI OBVIATE ENVIRONMENTAL ENG LTD

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Oxalic acid, green silicon carbide, alumina, etc. are all traditional stone polishing materials, but they cannot meet the needs of modern high-quality customers

Oxalic acid can polish stone, but it needs a lot of water. A large amount of polishing slurry will pollute the environment, and the gloss will disappear quickly. Although green silicon carbide and alumina can also polish stone, it will leave fine scratches and dry luster

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

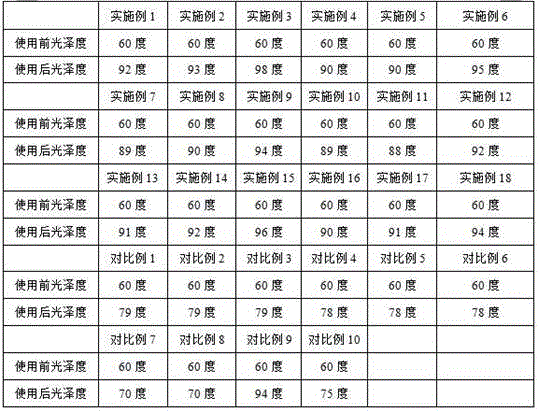

Effect test

Embodiment approach 1

[0088] Embodiment 1, a stone polishing powder is characterized in that it is at least composed of oxalic acid, abrasive grains, hydrogen oxalate, and iron oxide.

Embodiment approach 2

[0089] Embodiment 2 is the same as Embodiment 1, except that the molar ratio of oxalic acid and hydrogen oxalate is 1:2-5.

Embodiment approach 3

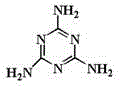

[0090] Embodiment 3 is the same as Embodiment 1, except that the polishing powder also includes melamine.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

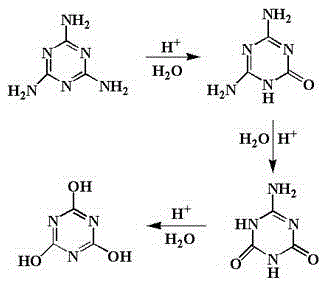

The invention relates to a stone polishing powder which is composed of oxalic acid, abrasive grains, bioxalate, iron oxide and melamine, wherein the mole ratio of the bioxalate to the oxalic acid is 1:(2-5), and the mole ratio of the melamine to the oxalic acid is 1:(5-10). The preparation method comprises the following steps: pouring the oxalic acid and abrasive grains, stirring uniformly, adding the bioxalate, continuing stirring uniformly, adding the iron oxide, reacting until the color is uniform under the action of the iron oxide, and finally, adding the melamine to synthesize the stone polishing powder. The oxalic acid is gradually hydrolyzed into other substances in the polishing process, thereby performing the polishing function and well protecting the stone from being corroded by the oxalic acid.

Description

technical field [0001] The invention relates to stone surface treatment technology, more specifically, the invention relates to a stone polishing powder. Background technique [0002] Oxalic acid, green silicon carbide, alumina, etc. are all traditional stone polishing materials, but they cannot meet the needs of modern high-quality customers. Oxalic acid can polish stone, but it needs a lot of water. A large amount of polishing slurry will pollute the environment, and the gloss will disappear quickly. Although green silicon carbide and alumina can also polish stone, it will leave fine scratches And dry luster. [0003] Modern customers demand both high gloss and oily feel, and long-lasting gloss without fine scratches. To meet market demand, the present invention provides a high-end stone polishing powder with long-lasting high gloss and oily feeling. Contents of the invention [0004] In order to solve the above problems, the invention provides a stone polishing p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09G1/02

CPCC09G1/02

Inventor 陈孝章陈应挺陈华实

Owner SHANGHAI OBVIATE ENVIRONMENTAL ENG LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com