Rapid assembly type steel corrugated plate arch bridge adaptable to large foundation displacement

A corrugated plate and assembled technology, which is applied in the field of fast-assembled steel corrugated plate arch bridges, can solve problems that affect the performance of corrugated steel culverts, poor adaptability of concrete foundations, and damage to steel bellows, so as to facilitate stacking and bundling and simple construction , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in combination with specific embodiments.

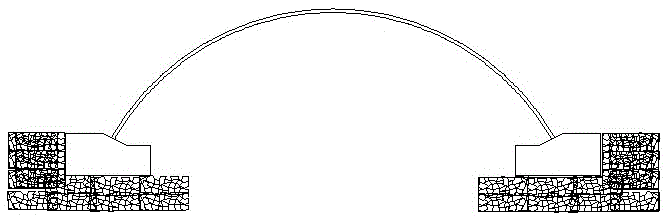

[0030] The invention relates to a rapidly assembled steel corrugated plate arch bridge that can adapt to large displacements of the foundation, comprising an arched culvert body and a concrete foundation. The arched culvert body is arc-shaped (low arc or high arc) or gate-shaped.

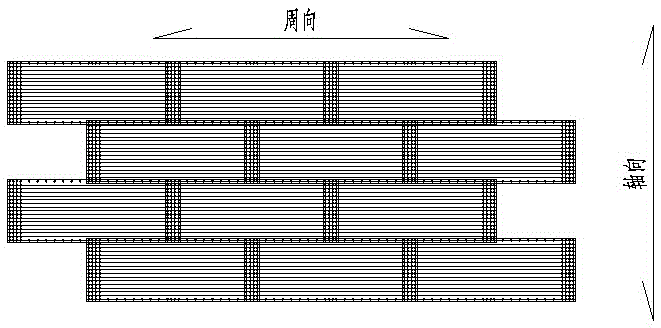

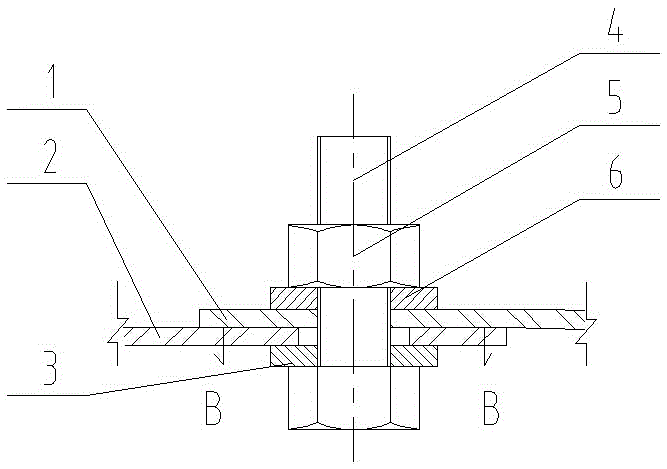

[0031] The arched culvert body is composed of multi-section corrugated plates circumferentially assembled into arch culvert units, and then composed of multiple arch culvert units axially connected, which increases the strength of the corrugated plate culvert, reduces manufacturing costs, and makes the overall construction simple and efficient. fast. The connection positions between two adjacent arch culvert units in the axial direction are arranged in a staggered manner. Corrugated plate pins are arranged at the bottom of both ends of the arch culvert unit, and a base 7 is arranged on the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com