A pile-beam structure integrated tower crane foundation structure and its construction method

A tower crane foundation and construction method technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of not meeting the requirements of the construction period and saving land, materials, pile foundation construction period, long intermittent time, etc., to reduce coverage blind spots, The construction operation is simple and the effect of saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] A pile-beam structure integrated tower crane foundation structure:

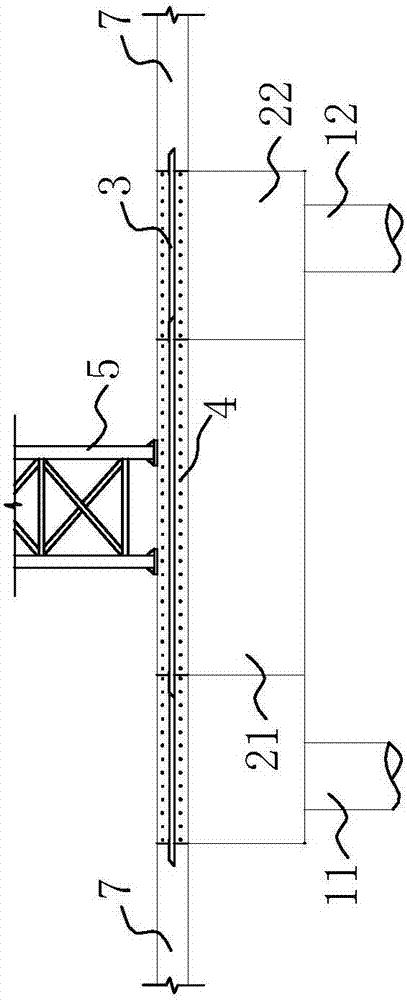

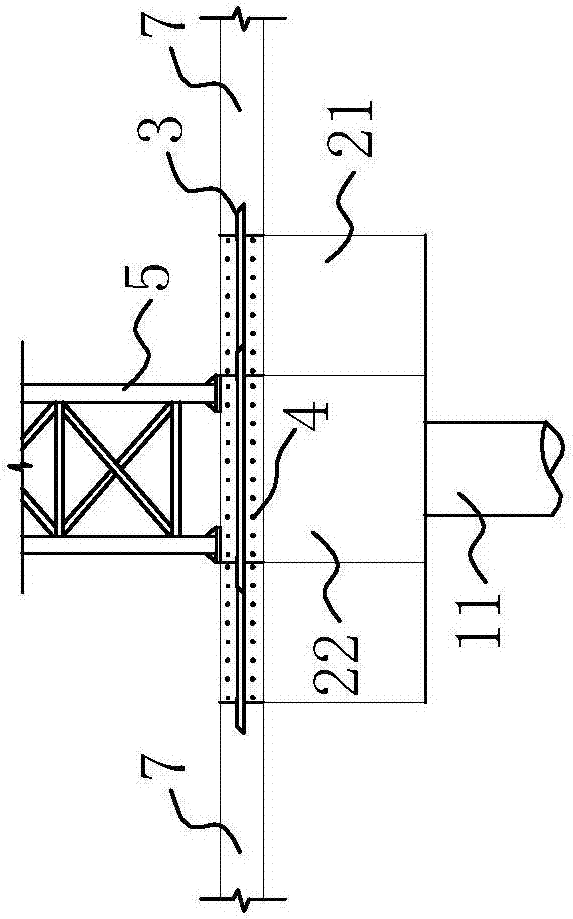

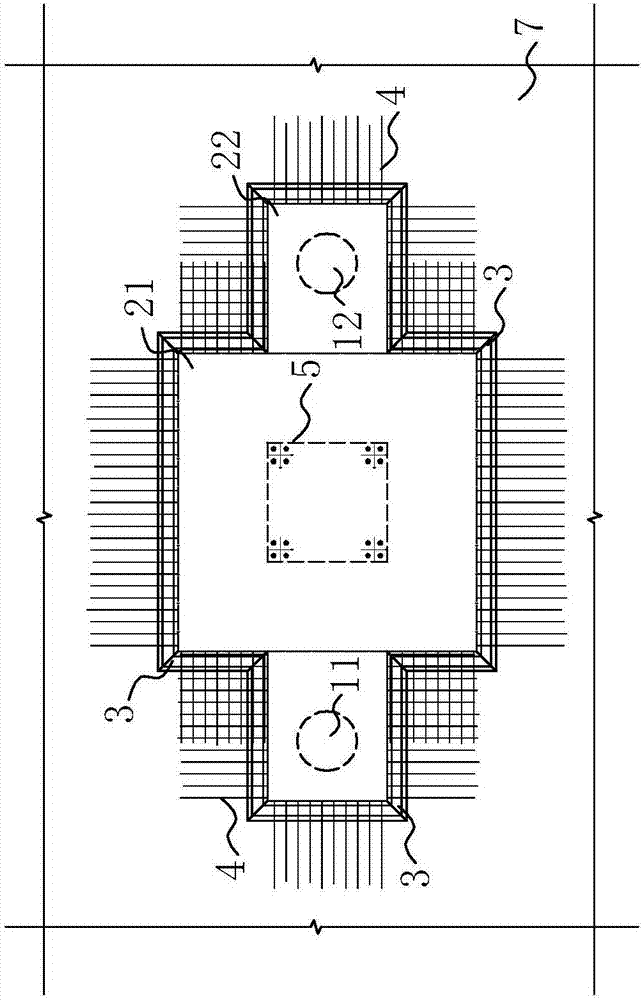

[0081] Such as Figure 1-Figure 4 As shown, the pile-beam structure integrated tower crane foundation structure includes the design engineering pile system, the cross foundation beam 2, the waterproof steel plate 3, the reserved rib 4 and the basement floor 7;

[0082] The design engineering pile system has two design engineering piles 11, 12, the two design engineering piles and the cross foundation beam 2 form a pile-beam structure integrated tower crane foundation, and the excess bearing capacity of the design engineering piles is used to bear the upper load and transfer the load to the foundation;

[0083] The cross foundation beam 2 is cross-shaped, comprising tower crane cap 21 and inter-pile connecting beam 22, consisting of cross foundation beam cushion 23, cross foundation beam reinforcing bar 24 and The brick tire mold 25 located at the edge of the cross foundation beam is composed of; the ...

Embodiment 2

[0089] A construction method for a pile-beam structure-integrated tower crane foundation structure, which is a construction method for realizing the pile-beam structure-integrated tower crane foundation structure described in Embodiment 1. The construction method uses BIM technology for three-dimensional modeling and assists in selecting the type and position of the tower crane. , using the excess bearing capacity of the design engineering piles, a cast-in-place reinforced concrete cross foundation beam is set between the two design engineering piles, and a water-stop steel plate and reserved reinforcement are set between the cross foundation beam and the basement floor, and the cross foundation beam It is poured together with the basement floor to form a joint force-bearing whole, thus forming a new type of pile-beam structure integrated tower crane foundation structure;

[0090] The construction process is as follows: selection of tower crane placement plan → universal founda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com