LNG pipeline crossing embankment system and its construction method

A construction method and pipeline technology, applied in the LNG transportation system and its construction field, to achieve the effects of easy control of the construction period, mature construction method and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

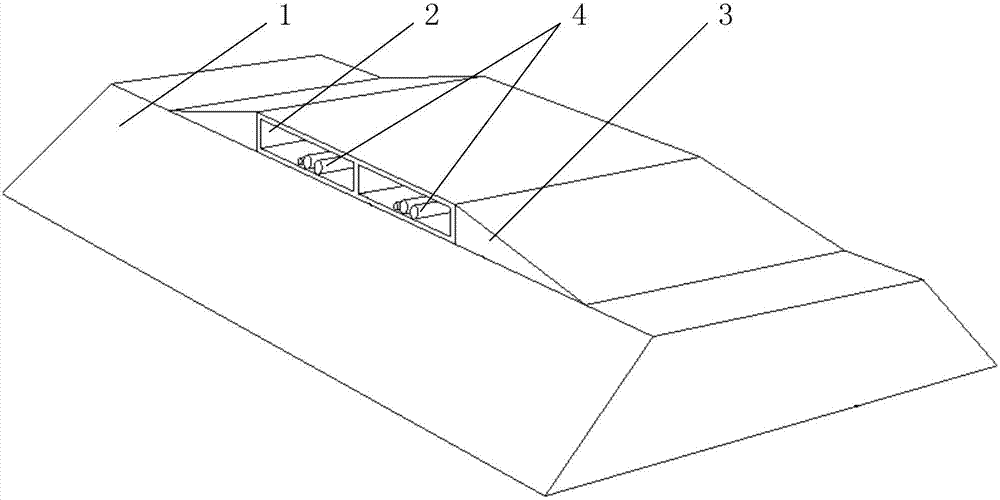

[0049] Such as figure 1 , Figure 4 with Figure 5 As shown, the LNG pipeline embankment system provided in this embodiment includes a dike 1, a box culvert 2, a slope 3, an LNG pipeline 4, an electric heating system 5, a cushion (not shown in the figure) and a waterproof layer 6, wherein , the box culvert 2 is stacked on the top of the dam 1, the slope 3 is set on both sides of the box culvert 2, and the LNG pipeline 4 passes through the dam 1 from the box culvert 2; Between the bottom plates of the box culvert 2, the waterproof layer 6 is arranged outside the box culvert 2.

[0050] In this embodiment, the dam 1 may be an earth dam, a stone dam or a concrete dam.

[0051] In this example, if Image 6 As shown, the LNG pipeline 4 includes an inner pipe wall 41 , a heat insulating layer 42 and an outer pipe wall 43 , wherein the heat insulating layer 42 is made of a cold-insulating material.

[0052] The construction method of the LNG pipeline crossing embankment system o...

Embodiment 2

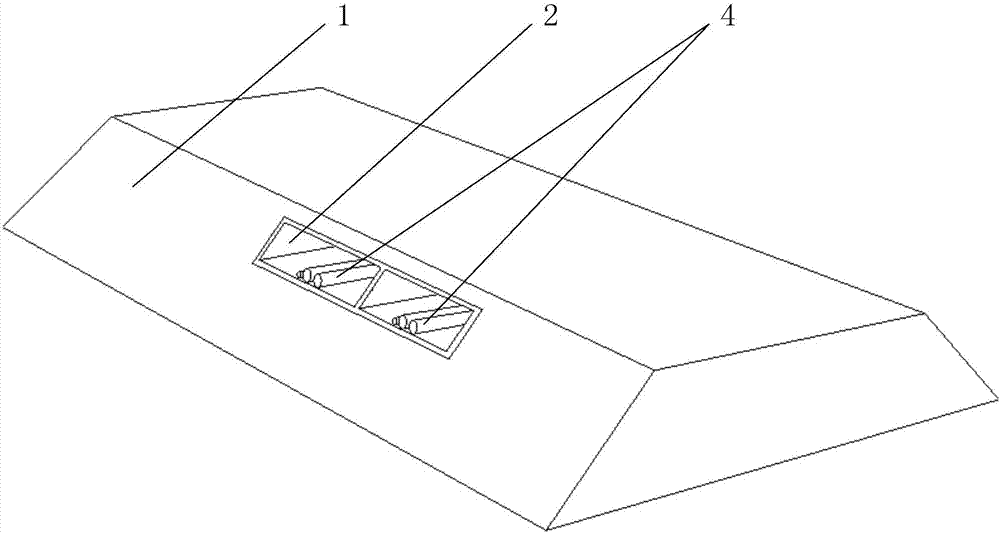

[0065] Such as figure 2 , Figure 4 with Figure 5 As shown, the LNG pipeline embankment system provided in this embodiment includes an embankment 1, a box culvert 2, an LNG pipeline 4, an electric heating system 5, a cushion (not shown in the figure) and a waterproof layer 6, wherein the box culvert 2 is set inside the embankment 1 and passes through the embankment 1, the LNG pipeline 4 passes through the embankment 1 from the box culvert 2, the electric heating system 5 and the cushion are sequentially arranged between the soil inside the embankment 1 and the bottom plate of the box culvert 2, waterproof The layer 6 is arranged outside the box culvert 2 .

[0066] In this embodiment, the dam 1 may be an earthen dam.

[0067] In this example, if Image 6 As shown, the LNG pipeline 4 includes an inner pipe wall 41 , a heat insulating layer 42 and an outer pipe wall 43 , wherein the heat insulating layer 42 is made of a cold-insulating material.

[0068] The construction ...

Embodiment 3

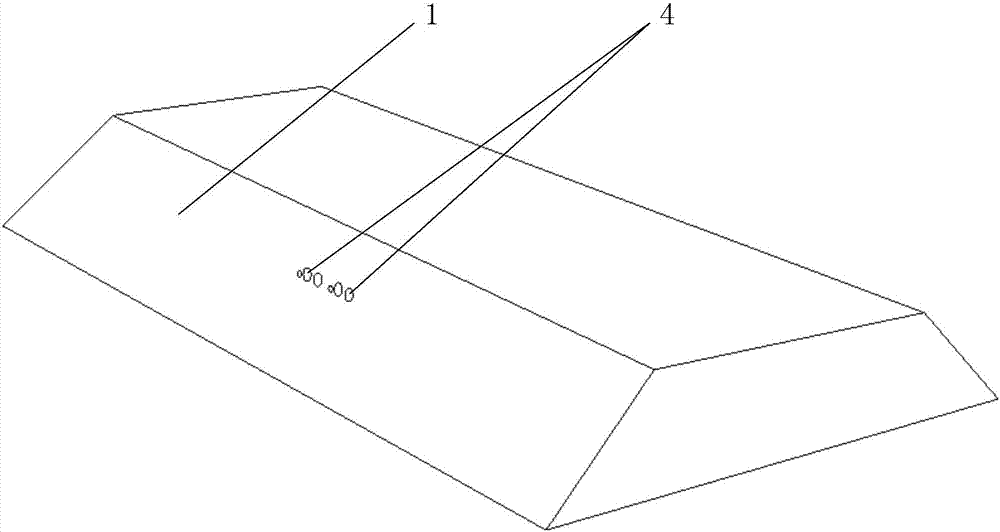

[0081] Such as image 3 with Figure 7 As shown, the LNG pipeline passing system provided in this embodiment includes a dam 1, an LNG pipeline 4 directly passing through the inside of the dam 1, and a waterproof pad 7 wrapping the outside of the LNG pipeline 4; wherein, the dam 1 can be an earthen dam; The LNG pipeline 4 includes an inner pipe wall 41, a heat insulating layer 42 and an outer pipe wall 43, the heat insulating layer 42 is made of a cold insulation material; the waterproof pad 7 can be a concrete layer or a metal material layer, and is used to reduce the water permeability of the LNG pipeline 4 .

[0082] The construction method of the LNG pipeline crossing embankment system of the present embodiment specifically comprises the following steps:

[0083] 1) Testing of the bearing capacity of embankment 1: Estimate the soil bearing capacity of each soil layer of embankment 1 after the construction of the LNG pipeline crossing embankment system. If the estimated so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com