An anti-slide pile structure with multi-area joint drainage function and its construction method

An anti-slide pile, multi-area technology, applied in the direction of foundation structure engineering, excavation, construction, etc., can solve the problems of reduced bending and shear resistance, cumbersome construction steps, and small bearing capacity of round piles, so as to improve the shear resistance , excellent drainage function, and the effect of improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the embodiments and accompanying drawings. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

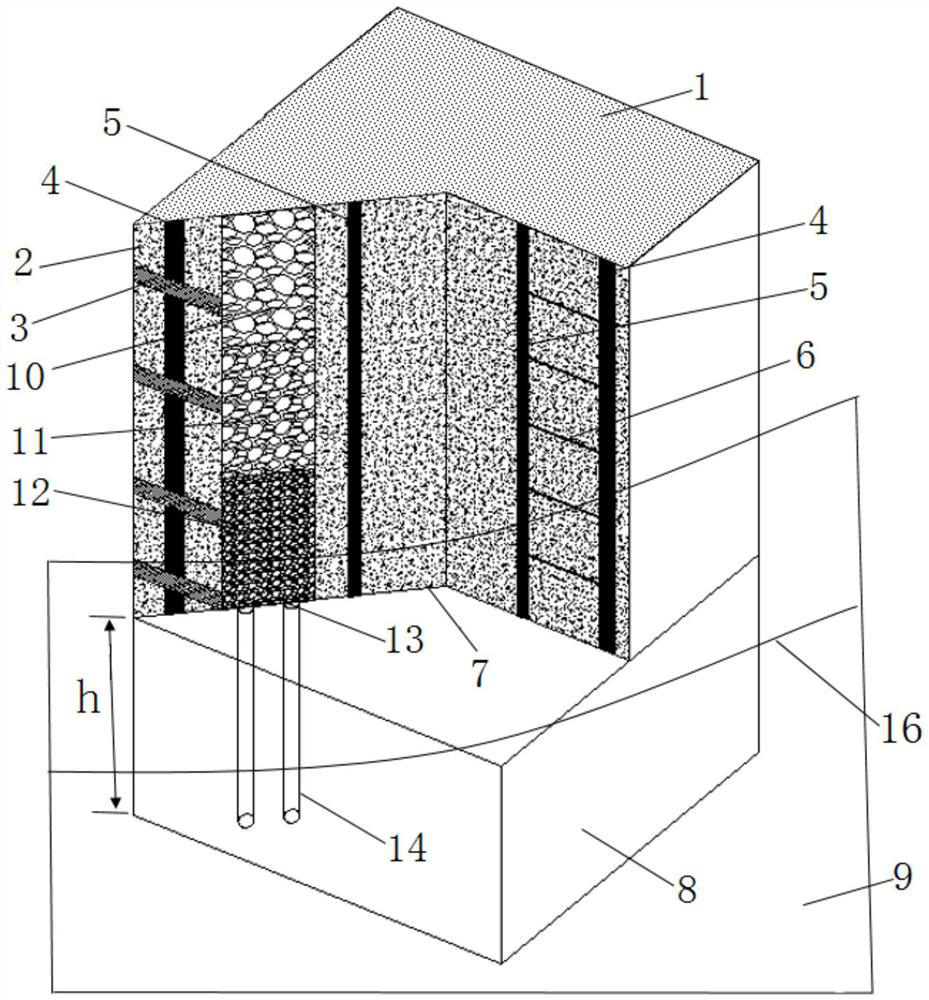

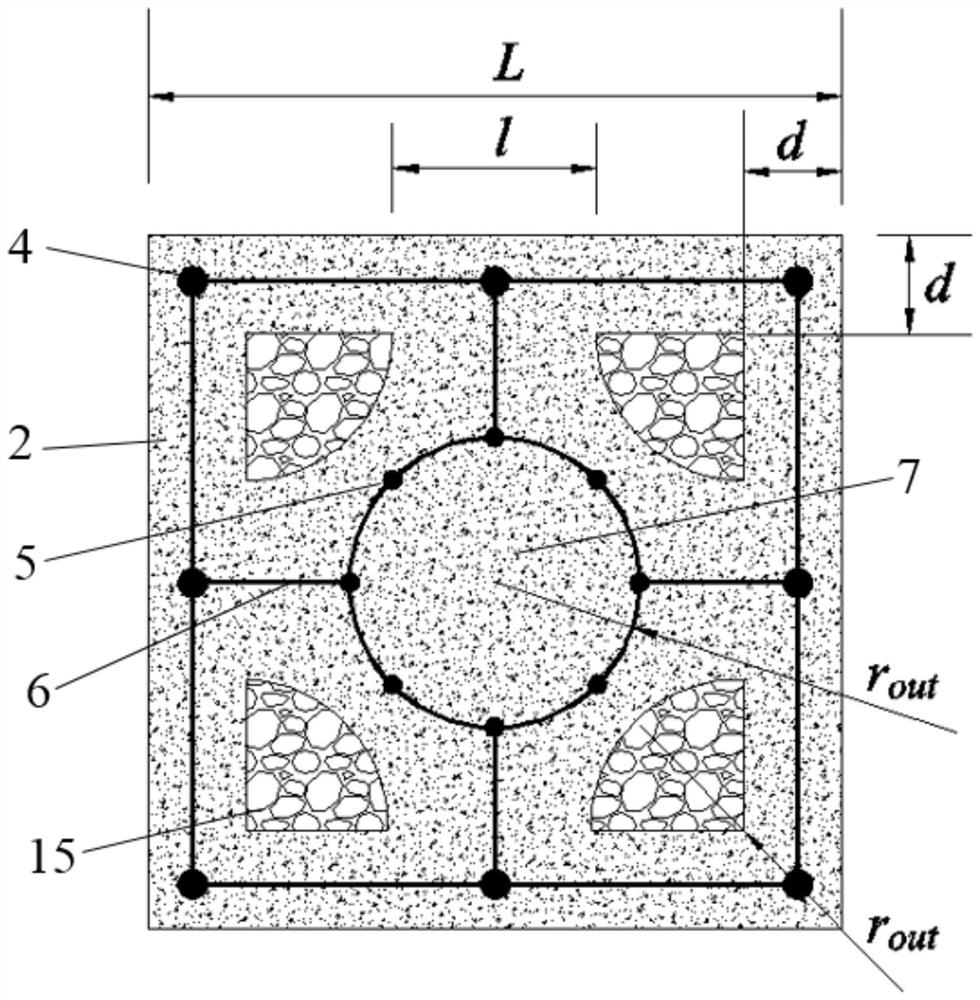

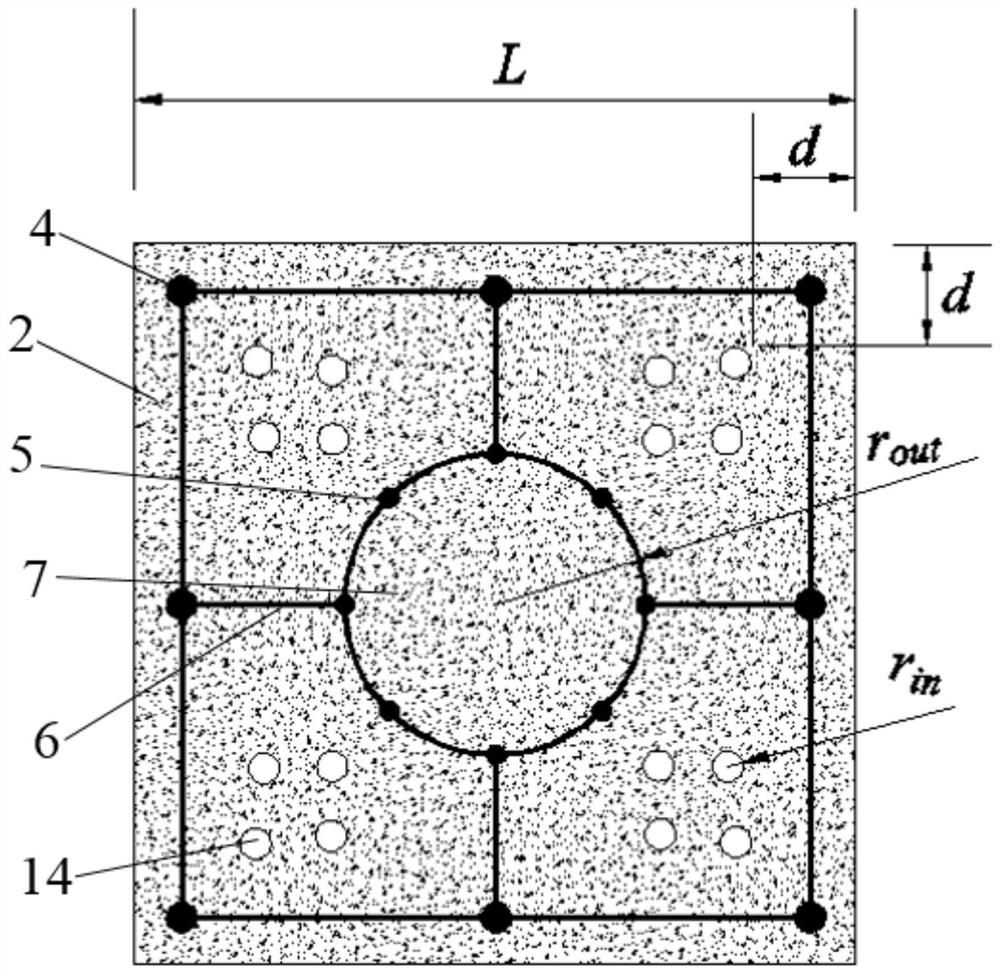

[0036] The invention provides an anti-slide pile structure (referred to as anti-slide pile, see Figure 1-3 ), the anti-sliding pile includes a lower pile bottom structure, an upper pile body structure and a steel cage as a whole; it is characterized in that the lower pile bottom structure and the upper pile body structure are connected as a whole through the overall reinforcement cage by the integral pouring method;

[0037] The overall reinforcement cage includes an inner circular reinforcement cage 5 and an outer square reinforcement cage 4 from the inside to the outside; the inner circular reinforcement cage 5 and the outer square reinforcement cage 4 are welded and connected as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com