Determination method of permeability rule of crack surrounding rock bolting and grouting in underground engineering

A technology for underground engineering and fractures, which is applied in the directions of measuring devices, permeability/surface area analysis, suspension and porous material analysis, etc. It can solve the problems of waste of resources, lack of data and data reference, etc., and achieve comprehensive and reliable data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0031] The method for measuring the seepage law of bolting and grouting in the surrounding rock of the crack in the underground engineering comprises the following steps:

[0032] Step 1: Collect large-scale rocks and rocks at the underground engineering site, use this as the research object to simulate the rock mass environment in the underground engineering, measure the degree of cracks in the large rocks, and obtain the crack density;

[0033] Step 2: Design an orthogonal test scheme for anchoring and grouting seepage in the surrounding rock for filling through fractures;

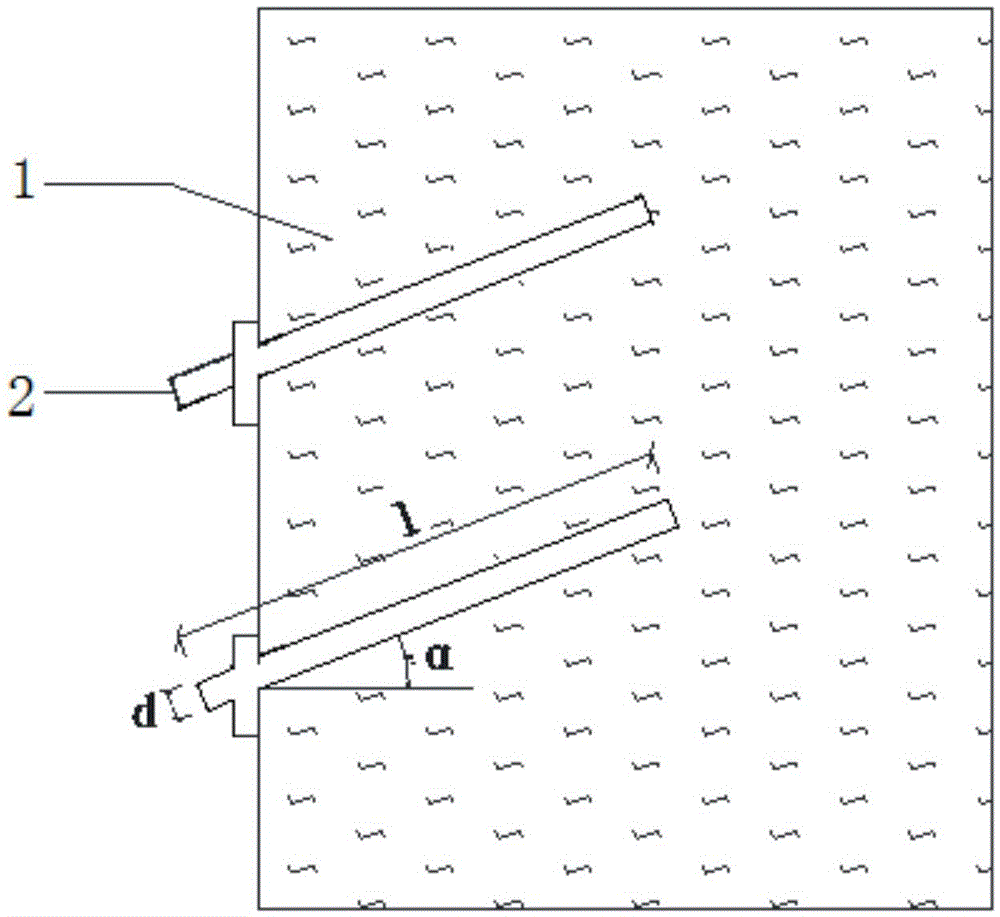

[0034] Orthogonal test scheme for anchoring and grouting seepage in surrounding rock filled through cracks, the process is as follows: borehole length l, borehole diameter d, inclination angle α, filler gradation ε, cement strength grade ω, water-cement ratio as n, grouting press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com