Rock pyrologger and pyrolytic analysis method

An analyzer and pyrolysis technology, which is applied in the field of rock pyrolysis and component analysis, can solve the problems of unmeasured content subdivision, and achieve high stability, high detection accuracy, and high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

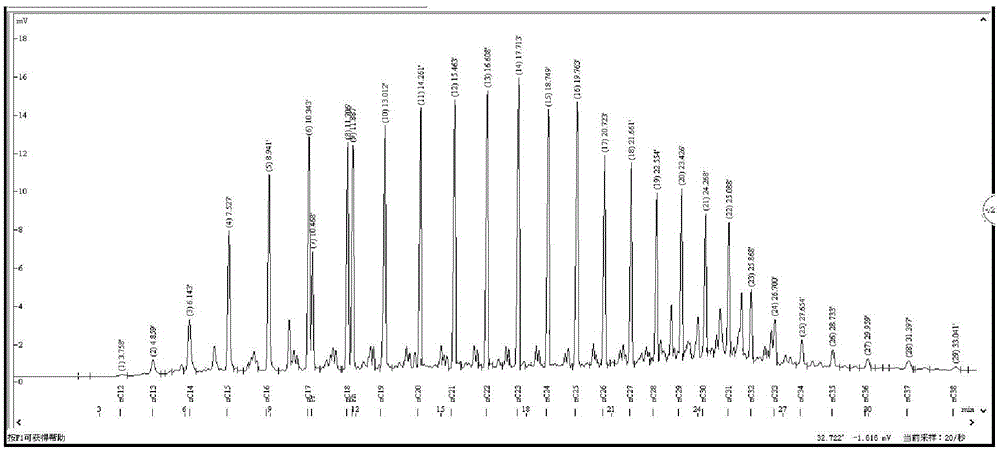

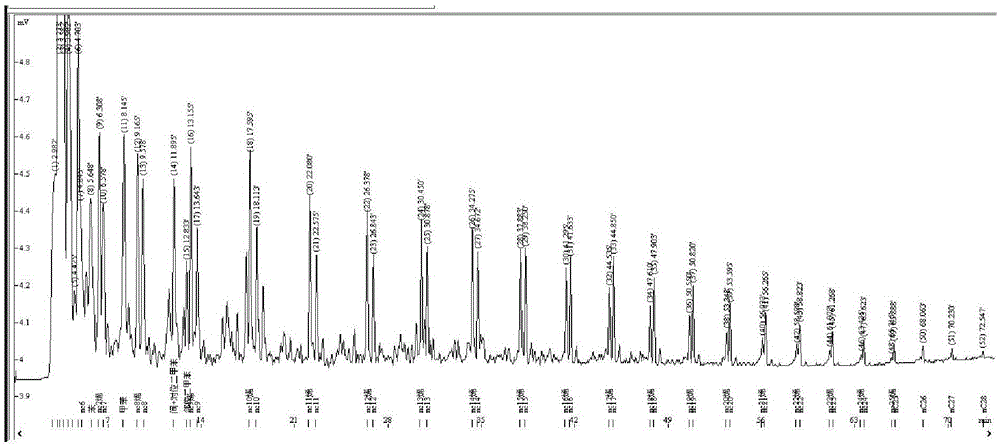

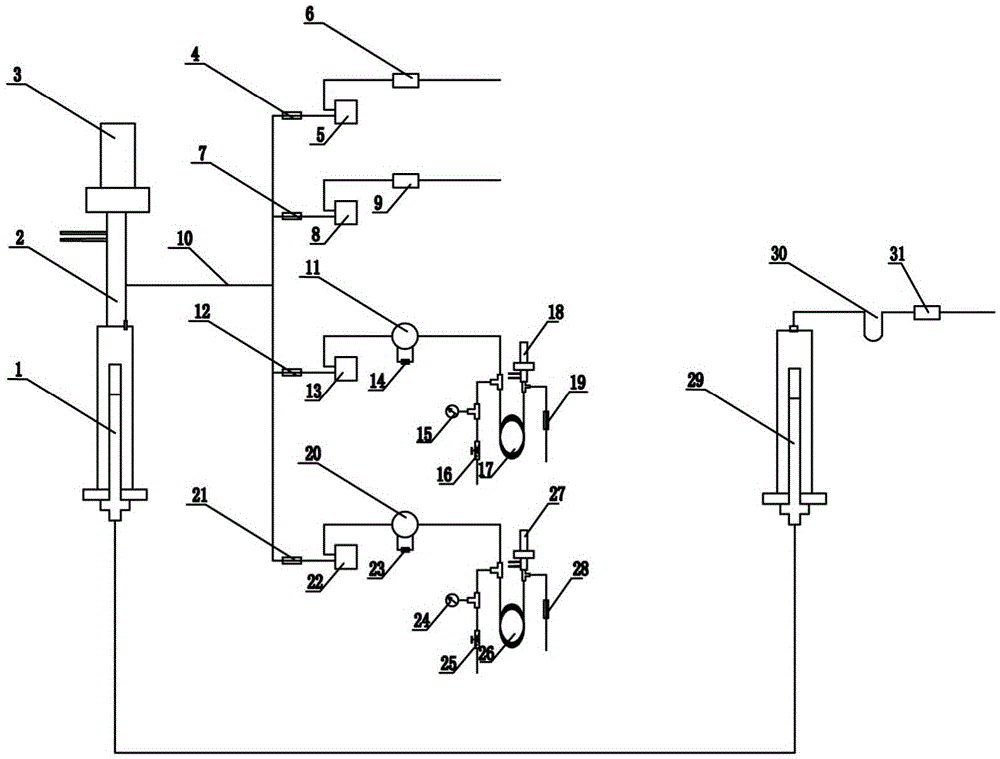

[0046] (1) Sample pyrolysis detection

[0047] (a) The pyrolysis furnace 1 heats the sample entering its interior from room temperature to 800 ° C, so that the hydrocarbons contained in A (source rock) in the sample are evaporated and cracked, and enter the FID detector I3 along the gas pipeline I2 , so as to detect the S contained in A (source rock) in the sample 0 , S 1 , S 2 content and the maximum cracking temperature Tmax value, as shown in Table 1;

[0048] Table 1

[0049] Sample basic parameters

[0050]

[0051] (b) The pyrolysis furnace 1 heats the sample entering its interior from room temperature to 800°C, so that the hydrocarbons contained in B (reservoir rock) in the sample are evaporated and cracked, and enter the FID detector I3 along the gas pipeline I2 , so as to detect the hydrocarbons S contained in B (reservoir rock) in the sample 0 , S 11 , S 21 , S 22 , S 23 content, as shown in Table 2;

[0052] Table 2

[0053]

[0054] (2) Pyrolysis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com