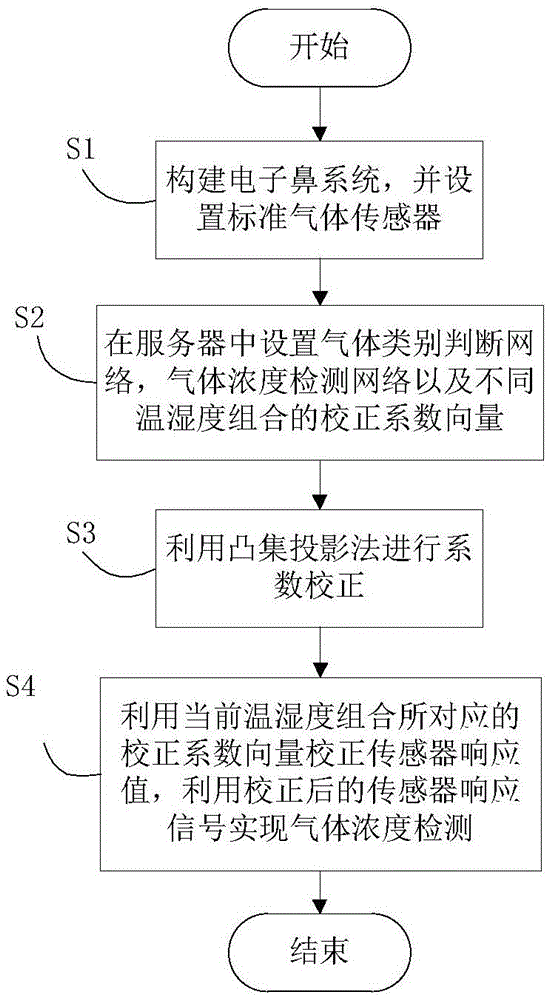

Concentration detection precision correction method based on projection onto convex set in electron nose system

A convex set projection and concentration detection technology is applied in the field of concentration detection accuracy correction based on convex set projection in the electronic nose system, which can solve the problems of sensor drift and sensor array difference, improve the detection accuracy, and solve the problem between electronic nose terminal boards. Differences and Effects of Long-Term Drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

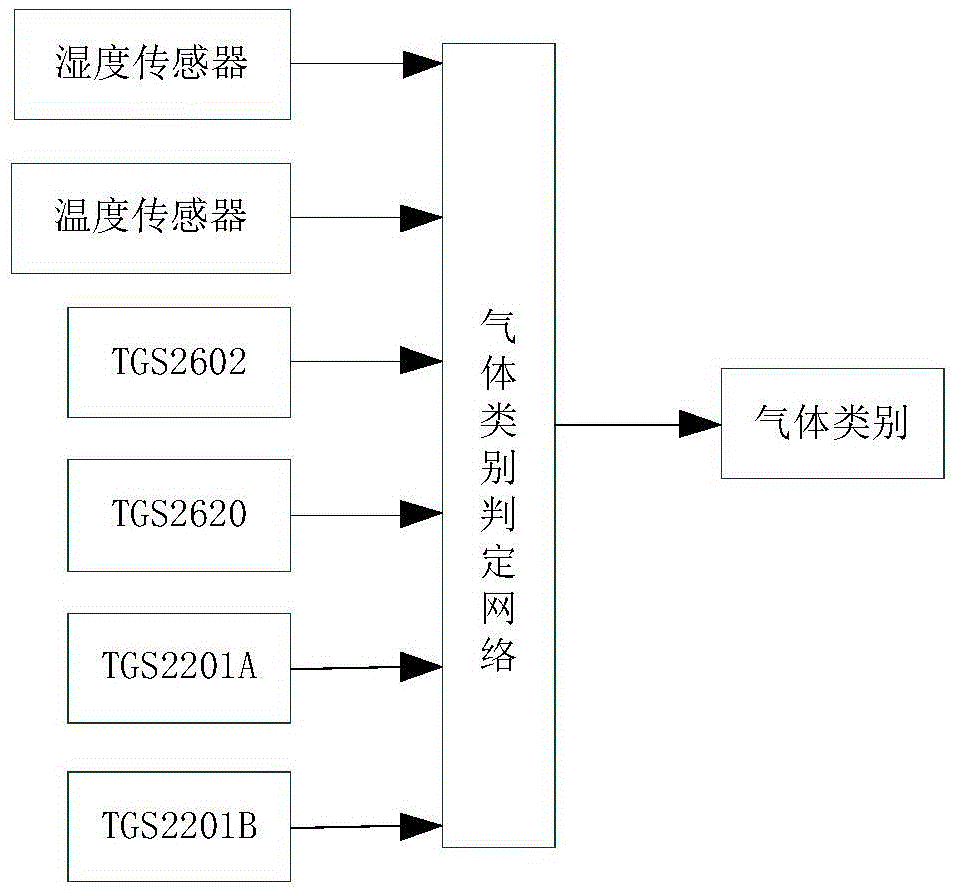

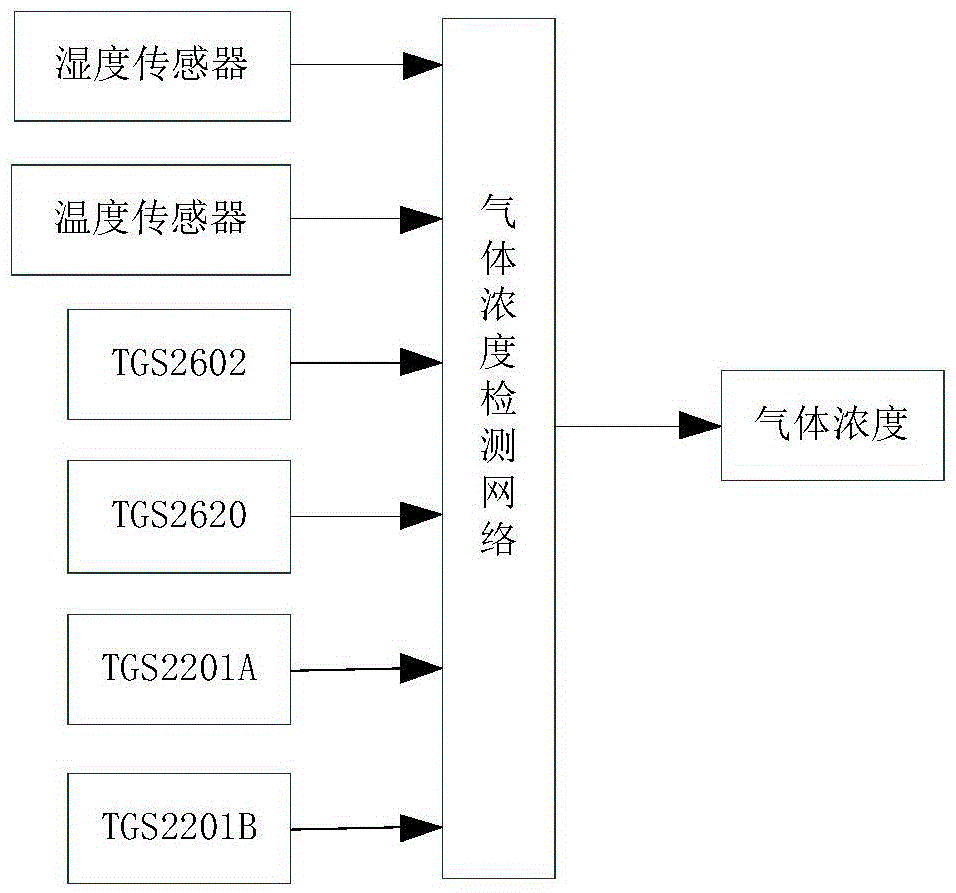

[0031] In this embodiment, the gas types to be detected by the electronic nose include formaldehyde, benzene, toluene, carbon monoxide, nitrogen dioxide and ammonia, and formaldehyde is set as the standard gas, and benzene, toluene, carbon monoxide, nitrogen dioxide and ammonia are the gases to be tested , The standard gas sensor is a high-precision electrochemical formaldehyde sensor, and the gas sensor signals to be corrected are TGS2602 response signal, TGS2620 response signal, TGS2201-A output signal and TGS2201-B output signal.

[0032] The electronic nose terminal is also provided with a microprocessor, an A / D conversion module, a communication module, a storage module, and a power supply module, and the sensor array converts the detected gas information into an electrical signal and then inputs it to the A / D conversion module , the A / D conversion module converts the analog signal into a digital signal and then inputs it to the microprocessor, the temperature signal and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com